High weather-resistant cold heading steel for 12.9-grade fasteners and production method thereof

A production method and fastener technology, which is applied in the field of cold heading steel production, can solve the problems of low strength of high weather resistance cold heading steel, and achieve the effects of increasing corrosion resistance, reducing costs, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

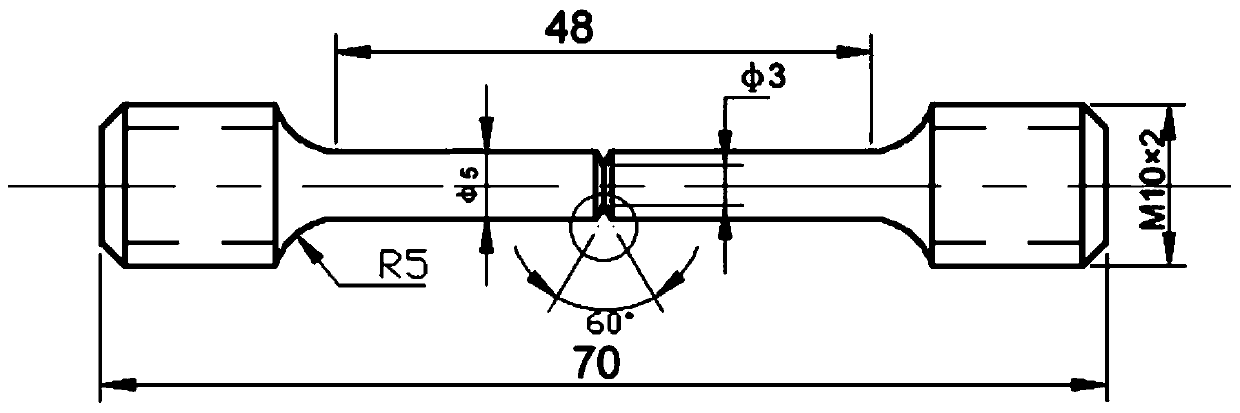

Image

Examples

Embodiment 1

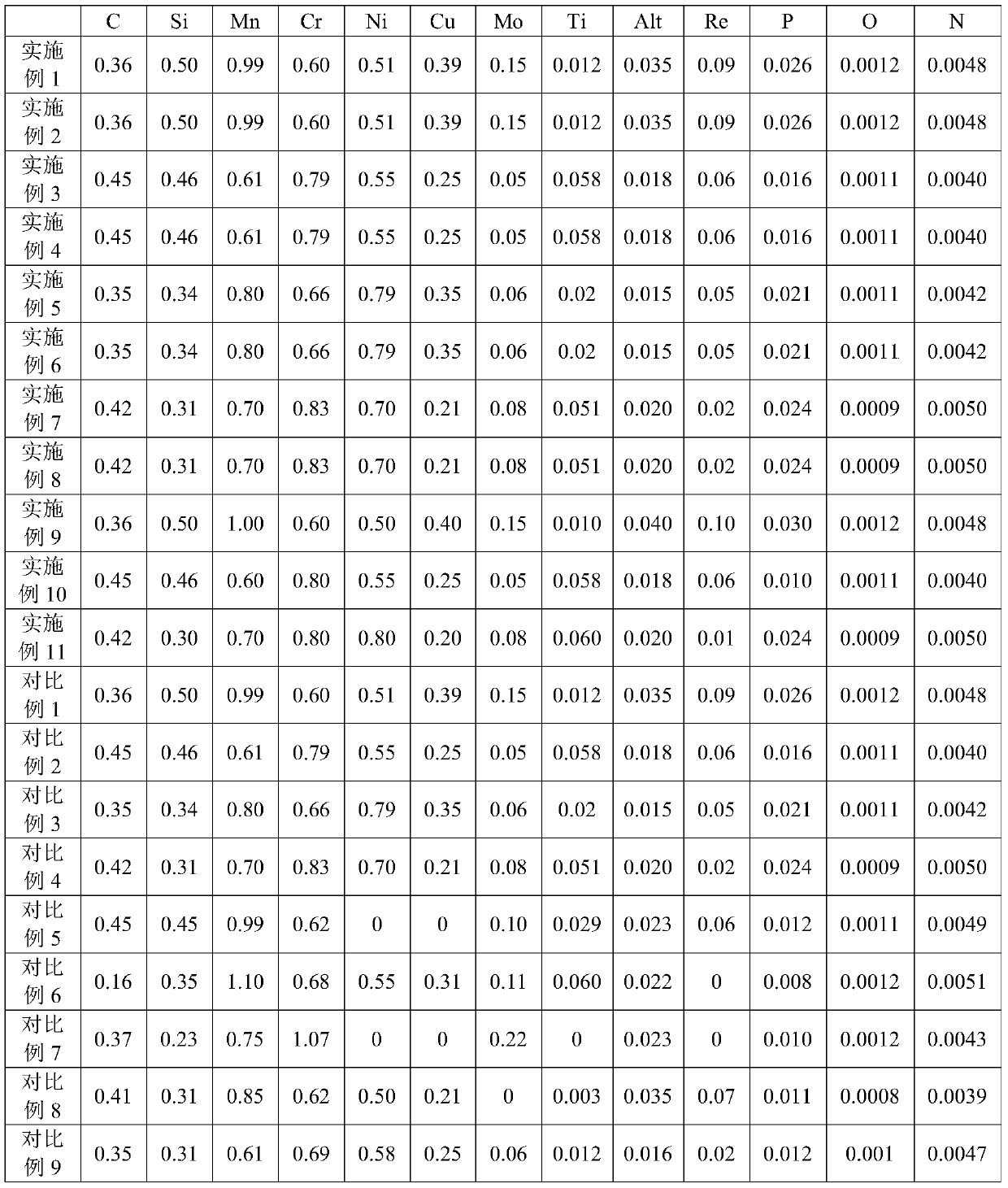

[0087] The main chemical components and mass percentages of the high weather-resistant cold heading steel for grade 12.9 fasteners in this embodiment are shown in Example 1 in Table 1.

[0088] A production method of high weather-resistant cold heading steel for 12.9 grade fasteners of this embodiment includes the following steps on the basis of the ingredients of this embodiment:

[0089] S1. Electric furnace smelting; during the smelting process, the oxygen is fixed before tapping, and the steel is left during the tapping process to avoid slag.

[0090] S2, LF furnace refining: during the LF furnace refining process, adjust elements such as C, Si, Mn, Cr, Ni, Cu, V, Re, P to the target value.

[0091] S3, RH vacuum degassing; degassing time ≥ 15 minutes, [H] content ≤ 1.5ppm after vacuum treatment, to avoid hydrogen embrittlement of bolts.

[0092] S4. Billet continuous casting; the temperature of the molten steel in the tundish is controlled at 10-40°C above the liquidus l...

Embodiment 2

[0101] The main chemical composition and mass percentage of the high weather-resistant cold heading steel for 12.9-grade fasteners in this embodiment are shown in Example 2 in Table 1.

[0102] A production method of high weather-resistant cold heading steel for 12.9 grade fasteners of this embodiment includes the following steps on the basis of the ingredients of this embodiment:

[0103] S1. Electric furnace smelting; during the smelting process, the oxygen is fixed before tapping, and the steel is left during the tapping process to avoid slag.

[0104] S2, LF furnace refining: during the LF furnace refining process, adjust elements such as C, Si, Mn, Cr, Ni, Cu, V, Re, P to the target value.

[0105] S3, VD vacuum degassing; degassing time ≥ 15 minutes, [H] content ≤ 1.5ppm after vacuum treatment, to avoid hydrogen embrittlement of bolts.

[0106] S4. Billet continuous casting; the temperature of the molten steel in the tundish is controlled at 10-40°C above the liquidus l...

Embodiment 3

[0115] The main chemical composition and mass percentage of the high weather-resistant cold heading steel for 12.9-grade fasteners in this embodiment are shown in Example 3 in Table 1.

[0116] A production method of high weather-resistant cold heading steel for 12.9 grade fasteners of this embodiment includes the following steps on the basis of the ingredients of this embodiment:

[0117] S1. Converter smelting; during the smelting process, the oxygen is fixed before tapping, and the steel is left during the tapping process to avoid slag.

[0118] S2, LF furnace refining: during the LF furnace refining process, adjust elements such as C, Si, Mn, Cr, Ni, Cu, V, Re, P to the target value.

[0119] S3, RH vacuum degassing; degassing time ≥ 15 minutes, [H] content ≤ 1.5ppm after vacuum treatment, to avoid hydrogen embrittlement of bolts.

[0120] S4. Billet continuous casting; the temperature of the molten steel in the tundish is controlled at 10-40°C above the liquidus line, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com