Hollowed-out base for liquid crystal display television

A technology for LCD TVs and substrates, which is applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., can solve the problems of short service life, high manufacturing cost, and heavy base weight, so as to reduce production costs, ensure bearing strength, and apply Sexually Enhanced Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

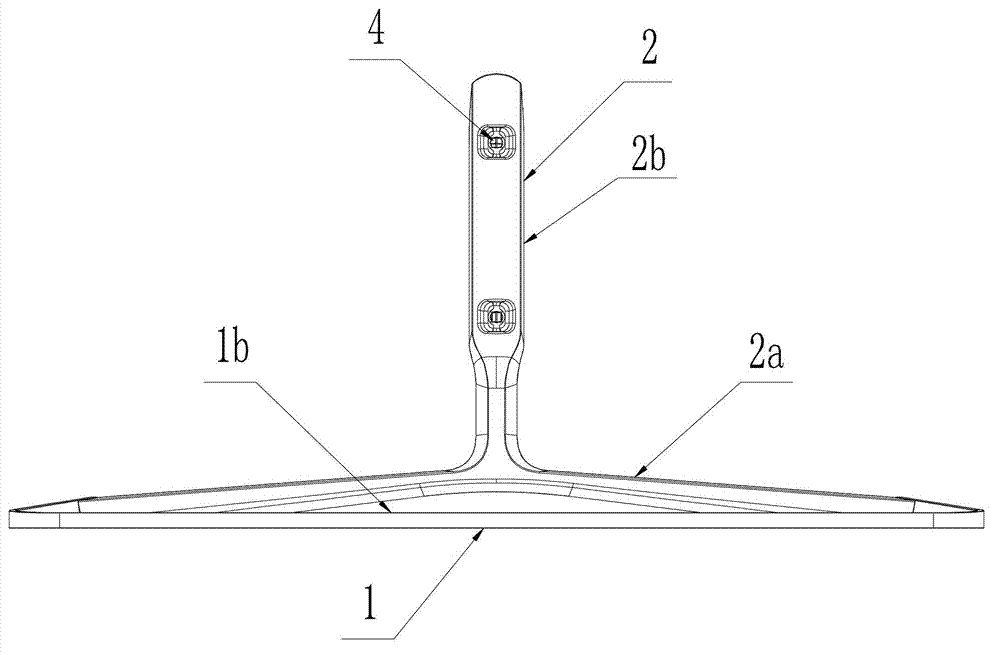

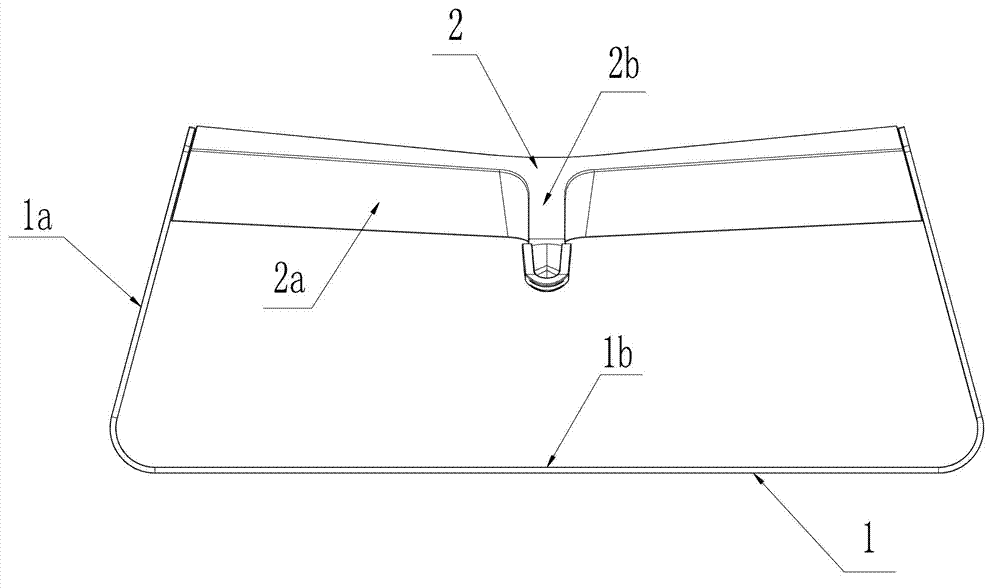

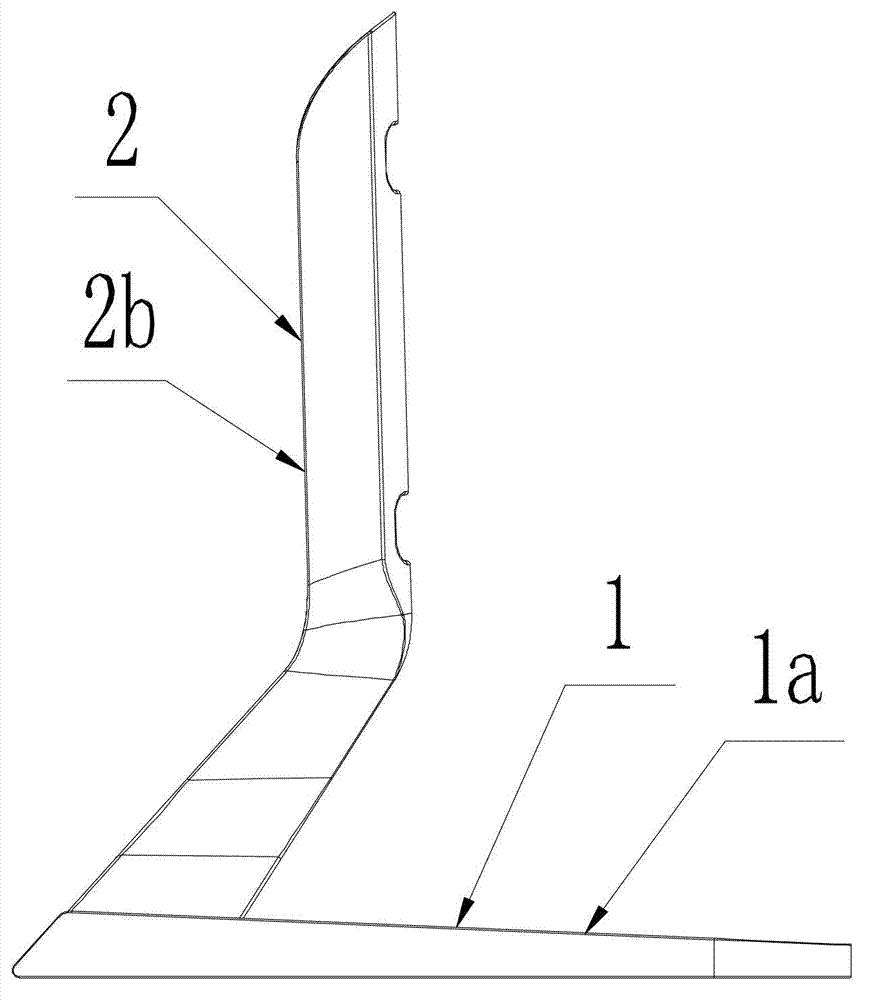

[0022] Example: Combine Figure 1 to Figure 5 As shown, the liquid crystal TV hollow base provided by the present invention is composed of a base and a support member fixed on the base as in the conventional technology, and the improvement of the present invention lies in that the base is a U-shaped metal folding base arranged laterally. The bending part 1, and the support member is an inverted T-shaped metal die-casting part 2 arranged longitudinally, and the two ends of the transverse part 2a of the inverted T-shaped metal die-casting part 2 are respectively connected to the two opposite sides 1a of the U-shaped metal bending part 1 fixed, and the vertical part 2b of the inverted T-shaped metal die casting 2 is used to fix the LCD TV.

[0023] In this embodiment, the U-shaped metal bending part 1 is a U-shaped iron bending part, and the inverted T-shaped metal die-casting part 2 is an inverted T-shaped aluminum die-casting part. Concrete combination Figure 5 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com