Small-sized LNG supplying system

A gas supply system, small technology, applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve problems such as inability to meet actual needs, and achieve the effect of reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

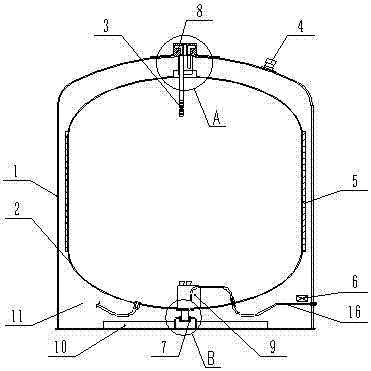

[0023] figure 1 It is a structural diagram of a small LNG gas supply system, including LNG cryogenic storage tanks and pipeline systems. The LNG cryogenic storage tank is a vertical double-cylinder high-vacuum multi-layer thermal insulation cryogenic tank structure, consisting of an outer tank 1 and an inner tank 2 Set composition. The outer tank body 1 is made of low-alloy steel plate, with an inner diameter of φ1850mm and a wall thickness of 8mm. The arc-shaped head at the bottom of the traditional pressure tank is canceled, and the bottom plate 10 directly adopts a flat plate structure to replace the arc-shaped head of the traditional tank body. The leg structure can be directly seated on the ground. For small tanks, it improves the flexibility of the equipment and is easy to move and install. The inner tank body 2 is made of austenitic stainless steel plate, and the Rp1.0 value is additionally inspected according to GB24511. The inner diameter is φ1700mm, the plate thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com