Extensible hose with special-shaped lining-ring connector and injection molding method thereof

A telescoping hose and injection molding technology, which is applied in the direction of pipes/pipe joints/pipe fittings, hose connection devices, mechanical equipment, etc., can solve the problems that cannot meet the requirements of internal hardness and external softness, and achieve a practical and feasible manufacturing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

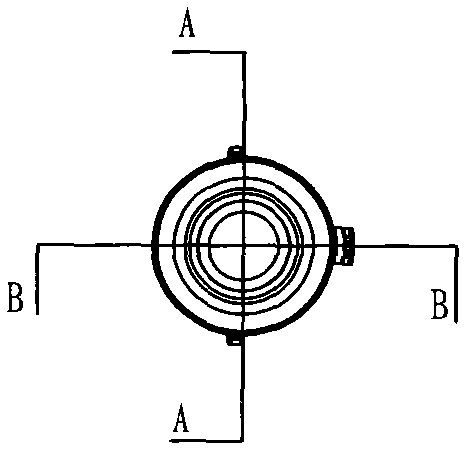

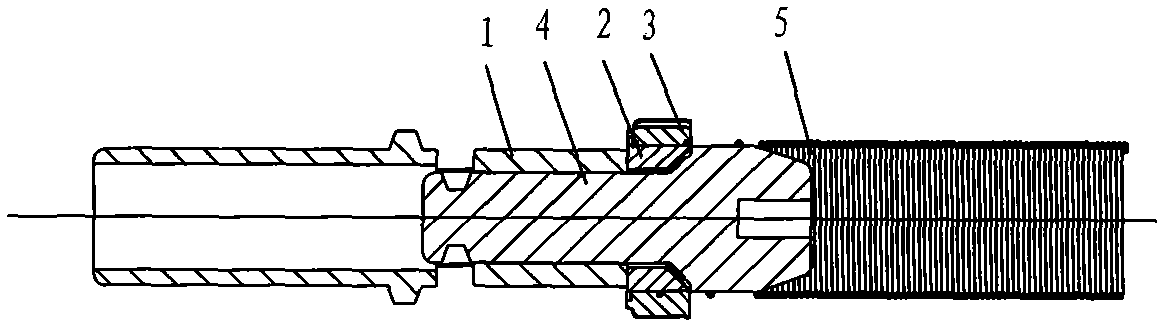

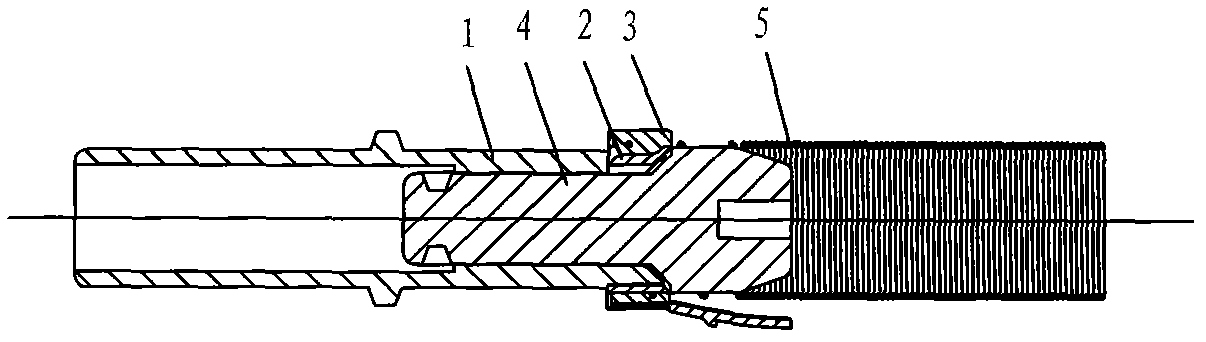

[0029] For the telescopic hose with a special-shaped ring connector in this embodiment, see figure 2 , image 3 , with a hose body 5 embedded with a spiral steel wire, one end of the hose body is embedded with a hard plastic lining 2, and the soft plastic joint 3 is wrapped outside to form a connecting head. The outer circle of the hard plastic liner 2 has a spiral guiding rib 2-1 (see Figure 5 ), the inner hole has a concavo-convex structure that plays a role in guiding and positioning the connecting piece—the axial ribs 2-3 distributed at intervals, and one end extends out of the hook 2-2. The end of the hose main body 5 is stretched and twisted on the hard plastic liner 2 . The soft plastic joint 5 is ring-shaped, and outside the end of the hose main body 5 with the hard plastic lining 2 embedded in the tight hoop, the hose main body 5 and the hard plastic lining 2 become an integral body tightly fitted after injection molding.

[0030] Since the inner hole of the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com