Shock-resistant ultrahigh-pressure pipe joint

A technology of high-pressure joints and pipe joints, applied in the direction of pipes/pipe joints/pipe fittings, sealing surface connections, mechanical equipment, etc., can solve the problems of poor seismic performance, hidden safety hazards, falling off, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

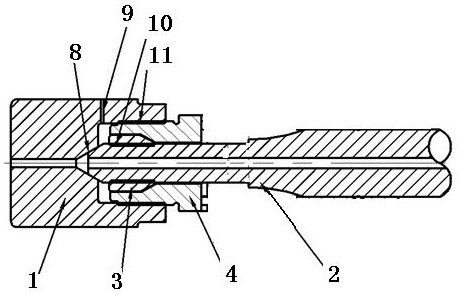

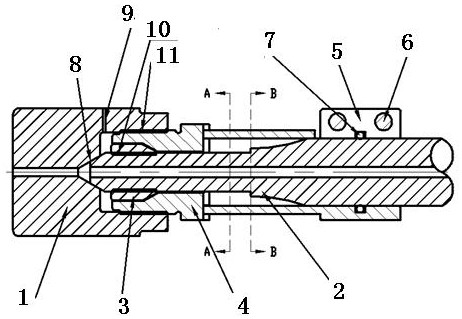

[0024] Such as Figure 2-4 shown.

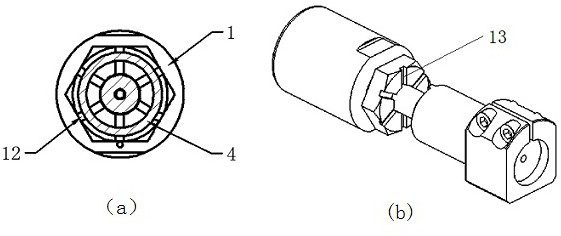

[0025] An anti-seismic ultra-high pressure pipe joint comprises a high pressure joint 1, a high pressure pipe 2, a screw washer 3 and a screw sleeve 4. The water inlet end of the water outlet hole of the high-pressure joint 1 has a frustum structure, and the water outlet end of the high-pressure pipe 2 has a frustum structure 8. Deliver high-pressure water to the high-pressure joint through a sealed channel; the high-pressure pipe 2 is covered with a screw washer 3, and the screw washer 3 is positioned in the inner cavity of the screw sleeve 4, and the screw sleeve 4 is fixed in the high-pressure joint 1 through threads, and the screw sleeve 4 is located The outer end of the high-pressure joint 1 has a hexagonal nut structure (such as image 3 ), to facilitate tightening, the thread direction of the screw washer 3 is opposite to the thread direction of the screw sleeve 4, and a safety pressure relief hole 9 is provided on the high-pressure...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the anti-rotation structure between the locking sleeve 5 and the high-pressure pipe 2 adopts a single key ( Figure 4 b), double bond ( Figure 4 c) or spline structure with ( Figure 4 d) instead of the rubber ring 7 ( Figure 4 a) structure, this key connection structure has stronger anti-rotation ability and better effect. In order to ensure the strength of the high-pressure pipe, it is best to thicken the pipe wall at the key connection position, and perform spot welding on the end surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com