Small hydraulic motor pump set structure

A technology of hydraulic motors and pump sets, which is applied in the direction of pumps, pump devices, pump components, etc., which can solve the problems of failure to meet the supporting requirements of amphibious equipment, low relative speed, poor sealing performance, etc., achieve light weight and increase service life , good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

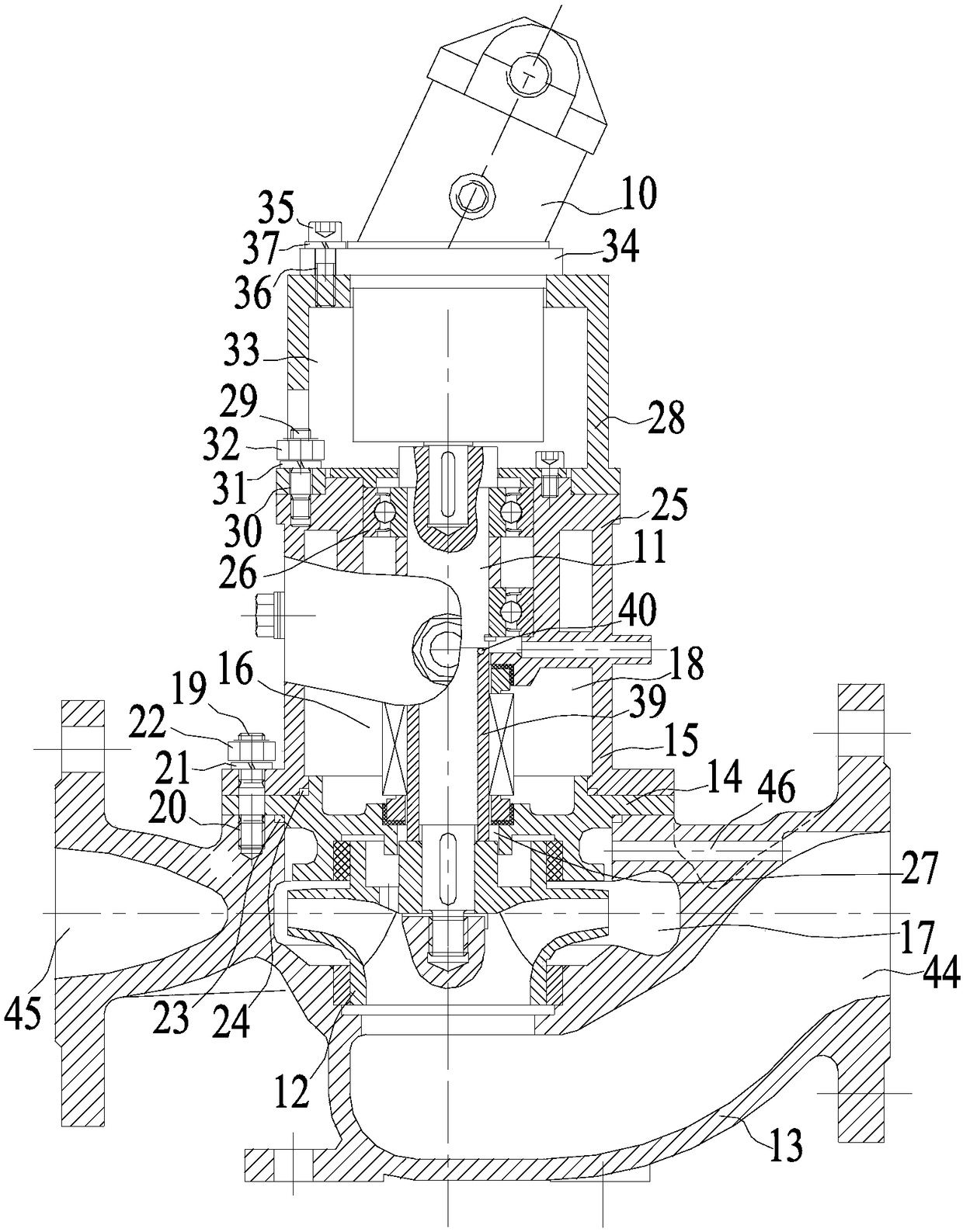

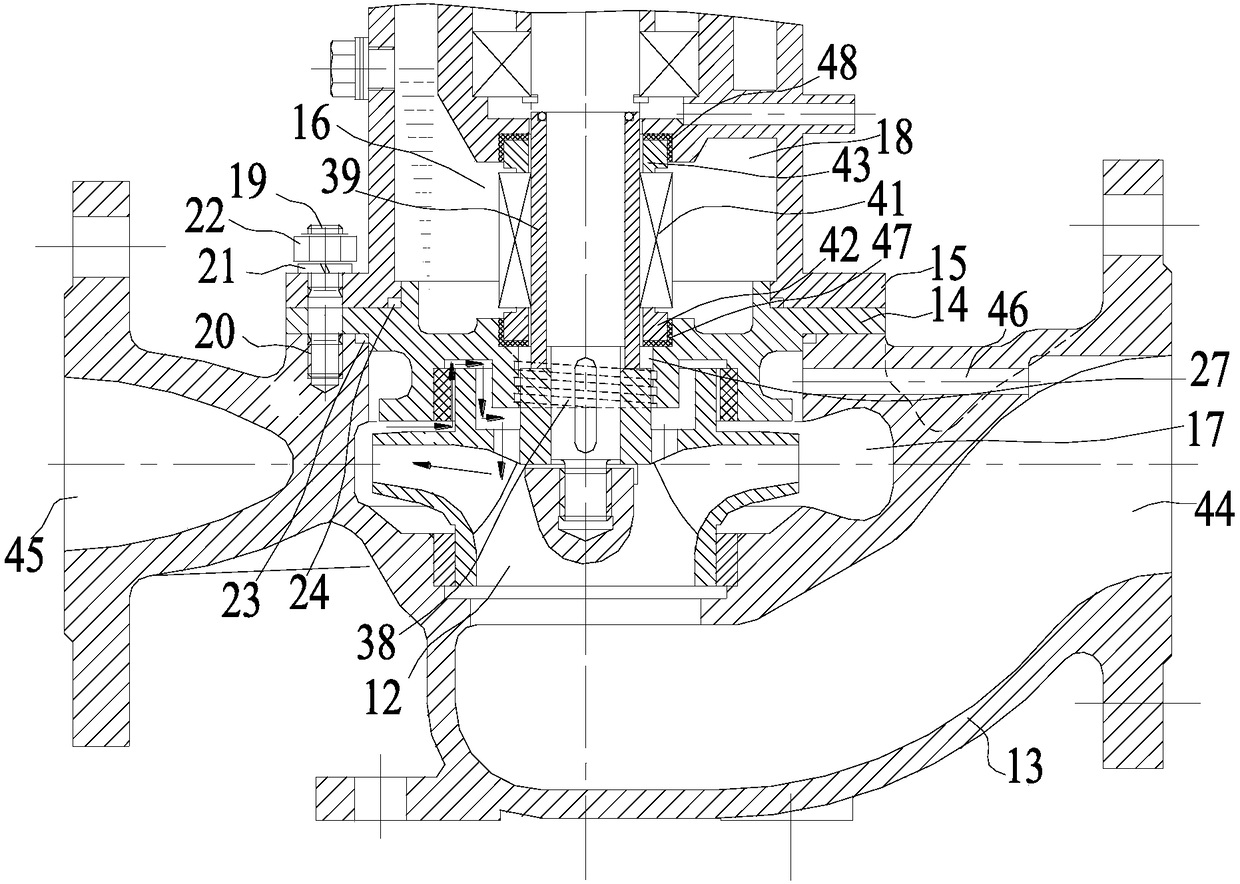

[0021] Such as figure 1 The pump group structure of a small hydraulic motor 10 shown includes a hydraulic motor 10, a main shaft 11, an impeller 12, a pump body 13, a pump cover 14, a seal bracket 15 and a mechanical seal assembly 16, and the main shaft 11 is connected to the hydraulic motor 10 in a transmission manner. The impeller 12 is fixed on the main shaft 11, the pump cover 14 is fixed on the pump body 13, the pump cavity 17 is formed between the pump cover 14 and the pump body 13, the sealing bracket 15 is fixed on the pump cover 14, the gap between the pump cover 14 and the sealing bracket 15 A mechanical seal chamber 18 for accommodating the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com