A preparation method of electronic grade low-oxygen ultra-high-purity titanium ultra-thin strip

An electronic-grade, ultra-thin strip technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of high cost and high energy consumption, and achieve simple rolling process, simplified production process, easy control and The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

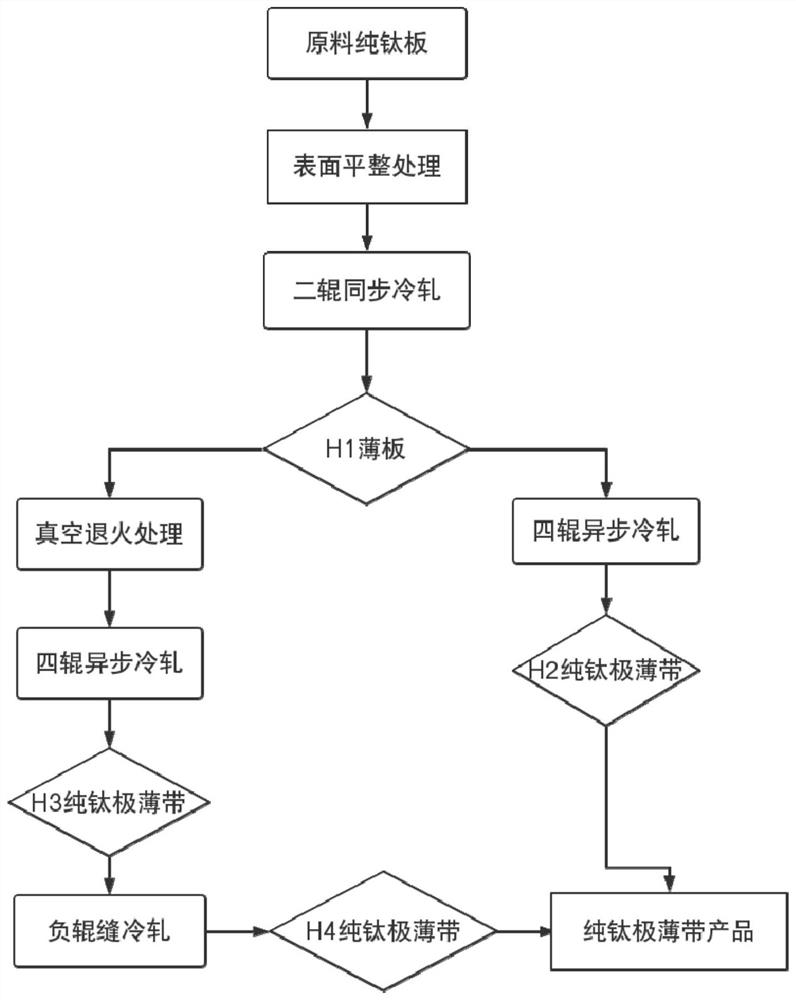

[0038] combine figure 1 The rolling process on the left side of the example, a method for preparing an electronic-grade low-oxygen ultra-high-purity titanium strip in this embodiment can prepare an electronic-grade low-oxygen ultra-high-purity titanium plate with a thickness of 8.6 mm into a thickness of 5 μm Ultra-thin strips of electronic-grade low-oxygen ultra-high-purity titanium. Follow the steps below:

[0039] Step 1. Cut the pure titanium plate with a thickness of 8.6mm into a square pure titanium slab of 60mm×60mm, and then grind and polish the surface of the ultra-high-purity titanium slab to make the surface of the slab smooth and smooth for subsequent rolling. Make preparations.

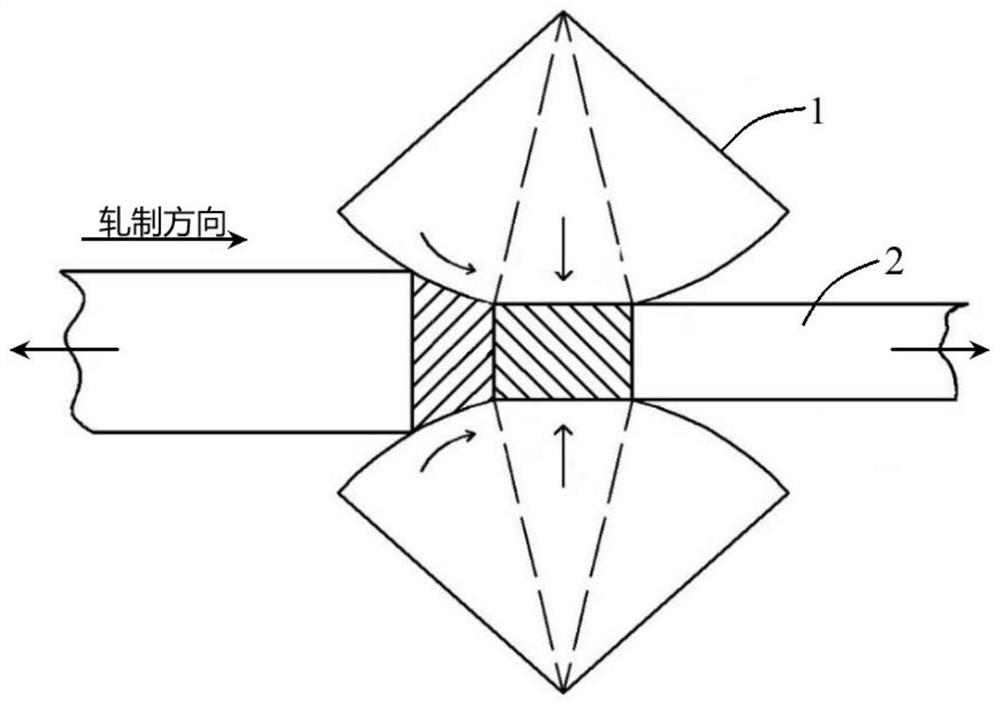

[0040]Step 2. Send the pure titanium rolled piece obtained in step 1 into a two-roll rolling mill, and directly reduce the thickness through multi-pass cold rolling to obtain a 0.8mm pure titanium sheet. The parameters are set as follows: the surface roughness Ra of the roll is 200nm, ...

Embodiment 2

[0050] A preparation method of an electronic-grade low-oxygen ultra-high-purity titanium strip in this embodiment is to prepare an electronic-grade low-oxygen ultra-high-purity titanium plate with a thickness of 8.6 mm to obtain an electronic-grade low-oxygen ultra-high-purity titanium plate with a thickness of 30 μm. Titanium extremely thin strip, preparation process is basically the same as embodiment 1, and its difference is, the parameter of rolling process is different, specifically as follows:

[0051] Step 1, cutting the pure titanium plate with a thickness of 8.6mm into a rectangular pure titanium slab of 50mm×60mm;

[0052] Step 2, the thickness of the pure titanium sheet obtained by rolling is 1mm, and the parameters are set as follows: the roll surface roughness Ra is 160nm, the roll speed is 90mm / s, the rolling pass is 12 passes, and the pass is pressed The rate is between 7% and 20%, and the total reduction rate reaches more than 88%;

[0053] Step 3. The cleanin...

Embodiment 3

[0057] A preparation method of an electronic-grade low-oxygen ultra-high-purity titanium strip in this embodiment is to prepare an electronic-grade low-oxygen ultra-high-purity titanium plate with a thickness of 5 mm to obtain electronic-grade low-oxygen ultra-high-purity titanium with a thickness of 30 μm. Extremely thin strip, preparation process is basically the same as embodiment 1, and its difference is that the parameter of rolling process is different, specifically as follows:

[0058] Step 1, cutting the pure titanium plate with a thickness of 5mm into a rectangular pure titanium slab of 60mm×60mm;

[0059] Step 2, the thickness of the pure titanium sheet obtained by rolling is 1mm, and the parameters are set as follows: the roll surface roughness Ra is 100nm, the roll speed is 80mm / s, the rolling pass is 10 passes, and the pass is pressed The rate is between 5% and 13%, and the total reduction rate reaches more than 80%;

[0060] Step 3. The cleaning temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com