Method for producing aluminum oxide by high sulfur bauxite

A high-sulfur bauxite and alumina technology, applied in the direction of alumina/hydroxide preparation, can solve the problems of high cost, poor desulfurization effect, large investment in flotation desulfurization equipment, etc., and achieve low production cost, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

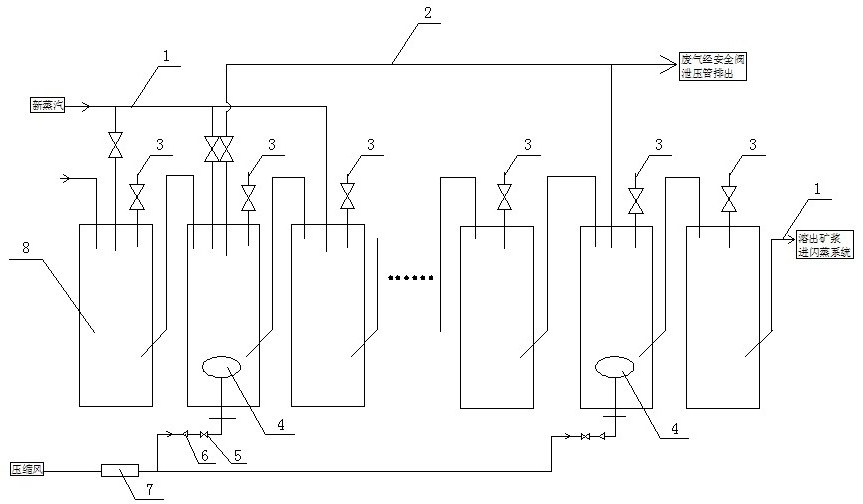

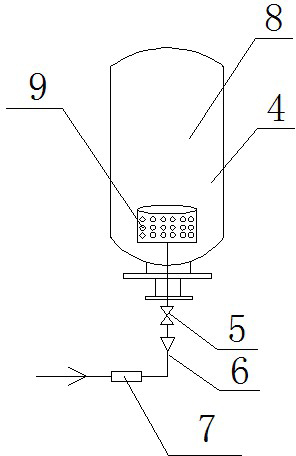

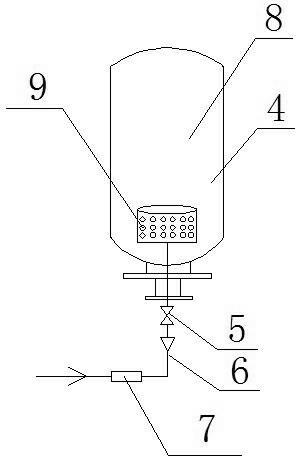

Method used

Image

Examples

Embodiment Construction

[0019] 1 Raw material preparation

[0020] The bauxite from the mine is crushed in the crushing station and then transferred to the ore unloading station, together with the purchased ore, it is unloaded into the mine bin and then transferred to the homogenization warehouse for distribution. The purchased lime is unloaded into the ash unloading silo and then transferred to the lime silo for lime digestion and raw material grinding batching.

[0021] The aluminum ore after homogenization in the homogenization warehouse is reclaimed horizontally by a double bucket wheel reclaimer, and then sent to the aluminum ore warehouse of the raw material grinding head through the belt conveyor, and then added to the rod mill through the apron feeder and the belt; the lime It is fed into the rod mill through electronic belt scales and belts; and the evaporation cycle mother liquor sent through the pipeline is added into the rod mill together. The unqualified pulp enters the ball mill thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com