Prepraiton method of high-carbon metallized pellets for electric furnace

A technology of metallized pellets and high carbon, which is applied in the field of iron and steel metallurgical electric arc furnaces, can solve the problems of insufficient density of recarburizers or foaming agents, insufficient carbon content, and easy breakage, so as to increase the density of pellets, pellets The effect of increased density and high iron content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

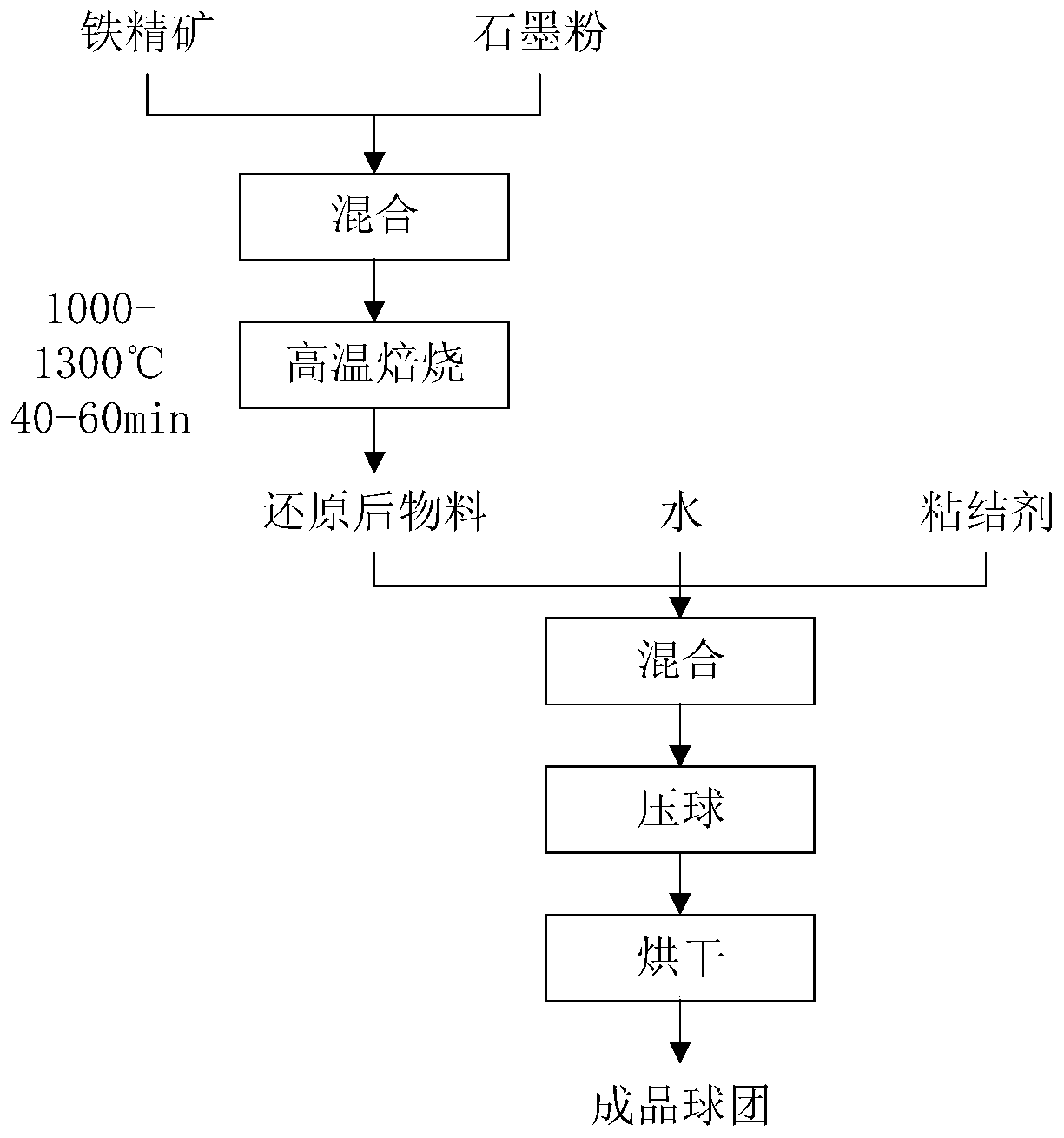

[0045] Pre-reduced iron ore concentrate high-carbon metalized pellets, the first application of production was carried out in a factory, and the pelletizing experiment was carried out. The production process of high-carbon metalized pellets is as follows:

[0046] 1) Using carbon powder with fixed carbon 96.28, ash content 6.24%, volatile content 5.56, and iron ore concentrate with 65.5% total iron, 6.44% silica, 0.018% phosphorus, and 0.041% sulfur. According to the C / Fe ratio of 1.8:1, do the ingredients and mix them evenly.

[0047] 2) After mixing uniformly, reduce in a rotary kiln at 1200°C for 40 minutes, the obtained metallization rate is 92.73%, and the residual carbon rate is 58.00%.

[0048] 3) Grind the reduction product

[0049] 4) Use bentonite as the binder and mix with water. The amount of binder is 6%, and the amount of water is 12%.

[0050] 5) After mixing uniformly, use a ball press to pelletize, the pressure of the ball press is 1000t.

[0051] 6) Final drying, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com