Method of recovering heat in hydrocarbon hydrogenating conversion process

A hydrogenation conversion and heat recovery technology, which is applied in lighting and heating equipment, heat generation by exothermic chemical reactions, heat generation by non-combustion exothermic chemical reactions, etc., can solve the problem of low preheating temperature of feedstock oil and reaction effluent Oversupply, increased investment and other issues, to achieve the effect of reducing the scale and investment of fractionation furnaces, saving fuel consumption, and reducing material grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

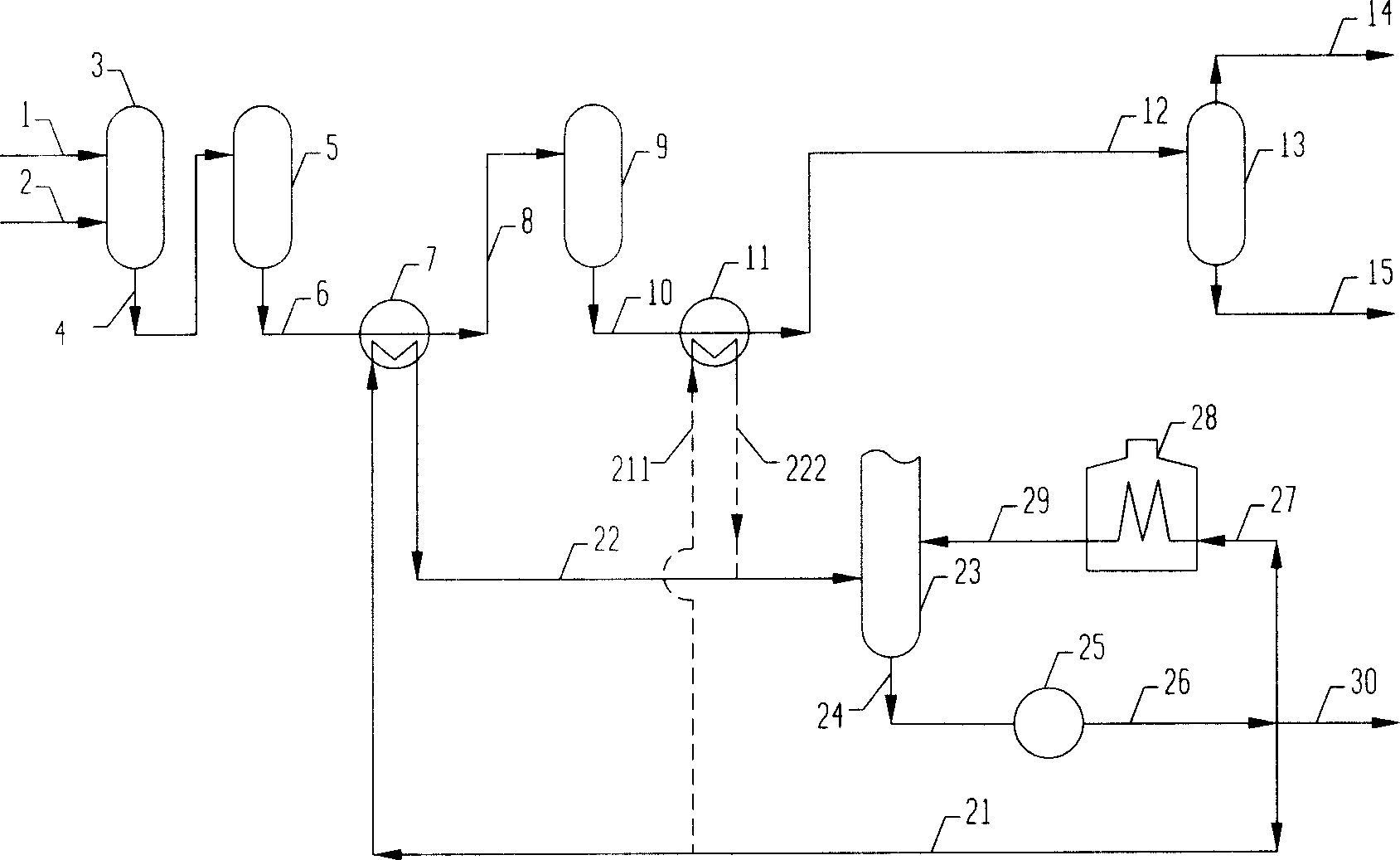

[0056] The coal tar hydrogenation unit has a processing capacity of 62.5t / h. The properties of the coal tar are shown in Table 1, the operating conditions of the reaction part are shown in Table 2, and the embodiments of the present invention are shown in Table 3.

[0057] From the data listed in Table 3, it can be seen that:

[0058] ①Using the bottom oil of the fractionating tower as cold hot oil, recovering heat energy of 10.9MMkcal / h; saving 4,890 tons / year of standard fuel for the reboiler of the fractionating tower, worth 19 million yuan / year;

[0059] ② Save 29,100 standard cubic meters of hydrogen per hour, and reduce the investment in the hydrogen circulation system by about 6.5 million yuan;

[0060] ③Reduce the heat load of the reaction feed heating furnace by 4.20MMkcal / h, and reduce the investment by about 3 million yuan.

[0061]Although this embodiment takes a coal tar hydrogenation unit as an example, the features of the present invention shown by it are also ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com