Chlorinated polyethylene produced by one-step method and preparation method of chlorinated polyethylene

A technology of chlorinated polyethylene and high-density polyethylene, which is applied in the field of polymer compound preparation, can solve the problems of unusable sewage acid water, large production equipment area, and high equipment investment cost, achieving remarkable social and environmental benefits, The effect of reducing floor space and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

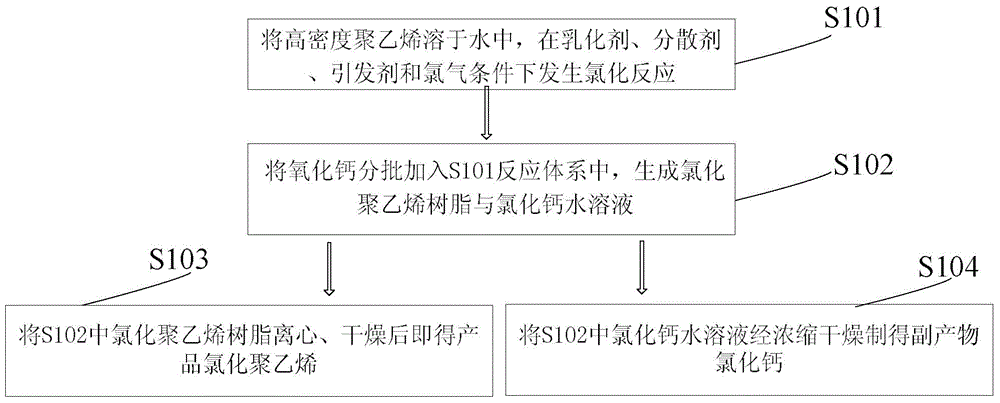

[0025] as attached figure 1 shown

[0026] One-step production of chlorinated polyethylene and preparation method thereof comprises the following steps:

[0027] S101: Dissolve high-density polyethylene in water, and chlorination reaction occurs under the conditions of emulsifier, dispersant, initiator and chlorine gas;

[0028] S102: adding calcium oxide into the reaction system of S101 in batches to generate chlorinated polyethylene resin and calcium chloride aqueous solution;

[0029] S103: Centrifuge and dry the chlorinated polyethylene resin in S102 to obtain the product chlorinated polyethylene;

[0030] S104: concentrating and drying the calcium chloride aqueous solution in S102 to obtain calcium chloride as a by-product.

[0031] Further, in S101, 15-25 mass parts of high-density polyethylene is added to 90-100 mass parts of water.

[0032] Further, in S101, the emulsifier is an anionic emulsifier or a nonionic emulsifier, and the amount added is 1-12‰ of the mass ...

Embodiment 1

[0042] Dissolve 4.0g of sodium dodecylbenzenesulfonate, 16.0g of OP-10, 20.0g of polyolefin pyrrolidone (k-30), and 140.0g of active silicon dioxide in 2000 g of water, put them into the reactor, and add 2.0g of Benzoyl peroxide, 200.0g of high-density polyethylene, closed reactor, heated up to 80°C, began to feed chlorine gas, when the temperature rose to 135°C, fed 220.0g of chlorine gas in total, stopped the chlorine flow, and the chlorine flow time was 2.5 hour, and then reacted at 135°C for 1 hour. Calcium oxide is added in batches during the reaction, the calcium oxide is added at a rate such that the pH value of the reaction system is controlled between 7.0-8.0, and the total amount of calcium oxide added is 80 g. When the kettle temperature drops to 80°C, the reaction system is purged with compressed air, the materials in the kettle are centrifuged, and the solid chlorinated polyethylene is dried to obtain a CPE product with a chlorine content of 35.5%; the centrifuged...

Embodiment 2

[0044] Dissolve 0.6g of sodium dodecylbenzenesulfonate, 1.4g of OP-10, and 10.0g of polyolefin pyrrolidone (k-30) in 2000g of water, put them into the reactor, and add 10.0g of benzoyl peroxide, 400.0g high-density polyethylene airtight reactor, heat up to 80°C, start to feed chlorine gas, when the temperature rises to 135°C, cumulatively feed 210.0g chlorine gas, stop chlorine flow, chlorine flow time is 2.5 hours, keep warm at 135°C for 1 Hour. Calcium oxide is added in batches during the reaction, the rate of addition of calcium oxide is as the criterion so that the pH value of the reaction system is controlled between 7.0-8.0, and the total amount of calcium oxide added is 160g. When the temperature of the kettle drops to 80°C, the reaction system is purged with compressed air, the materials in the kettle are centrifuged, and the solid chlorinated polyethylene is dried to obtain a CPE product with a chlorine content of 36.0%; the centrifuged mother liquor is concentrated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com