A self-catalytic denitrification system for sintering dust coupled with waste heat of sintering dust

A technology of self-catalysis and soot, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of low equipment investment and operating costs, difficult disposal of waste catalysts, and high operating costs, and achieve equipment investment and operating costs Low cost, reduced investment in denitrification equipment, and full use of waste heat in the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

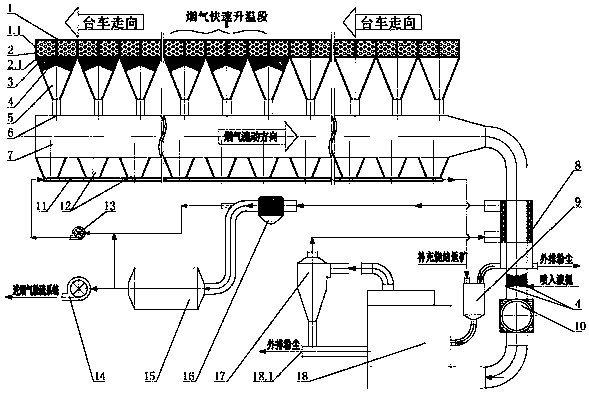

[0028] The system of the present invention will be further explained below in conjunction with the accompanying drawings:

[0029] The bottom of the trolley 1.1 of the sintering machine 1 is provided with a bellows 5, the outlet at the bottom of the bellows 5 is connected to the main flue 7, and the sintering machine 1 is sequentially divided into an ignition section, a head section, a flue gas rapid heating section and a There are 4 areas in the tail section, the ignition section is located at the front end of the sintering machine 1, and this area occupies 1-2 bellows length; the nose section is located in the front half of the sintering machine after the ignition section and extends to the middle of the sintering machine. The area accounts for 35-45% of the total length of the sintering machine; the rapid heating section of the flue gas is located in the middle of the sintering machine towards the tail of the machine, and this area occupies 2-4 lengths of the bellows; the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com