Chinese pennisetum drying method

A drying method, the technology of Pennisetum, applied in the direction of drying solid materials, drying gas arrangement, local agitation dryer, etc., can solve the problems of high drying cost, long drying cycle, difficult drying of grass stems, etc., and achieve low drying cost , short drying cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

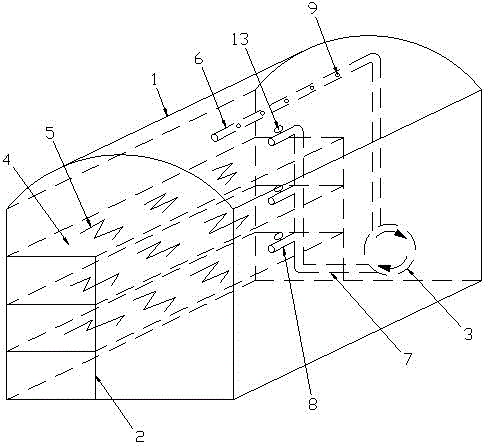

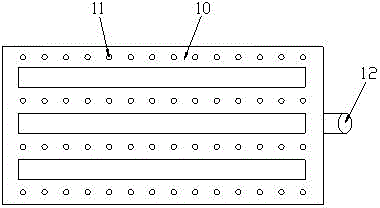

[0017] Such as Figure 1~3 Shown, a kind of pennisetum drying method comprises a kind of Pennisetum drying device, and this device comprises greenhouse 1, is provided with at least one drying bed frame 2 and at least one blower 3 in described greenhouse 1, and described drying The bed frame 2 is provided with a three-layer drying bed 4, the air grid 5 is laid on the drying bed 4, the air inlet of the blower 3 is connected with an air intake pipe 6, and the air intake end of the air intake pipe 6 is arranged in parallel on the greenhouse 1, the air outlet of the blower 3 is connected with an air outlet pipe 7, and the air outlet pipe 7 is provided with three branch pipes 8 respectively connected to the air grids 5 of each layer, and the branch pipes 8 are provided with air volume regulating valves 13. The air volume regulating valve 13 can also be arranged on the air intake end of the air grid 5; and proceed as follows:

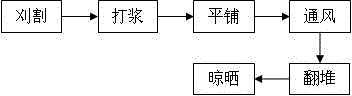

[0018] (1) Mowing: When Pennisetum grows to 1.5-2.5 met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com