Method for preparing bio-oil reactant and bio-oil from lignocellulosic biomass

A lignocellulosic and biomass technology, applied in the direction of fat production, fat oil/fat production, etc., can solve the problems of chemical composition reduction, bio-oil chemical composition surge, uncontrollable and other problems, so as to suppress the generation of gas and reduce the process flow , Improve the effect of application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

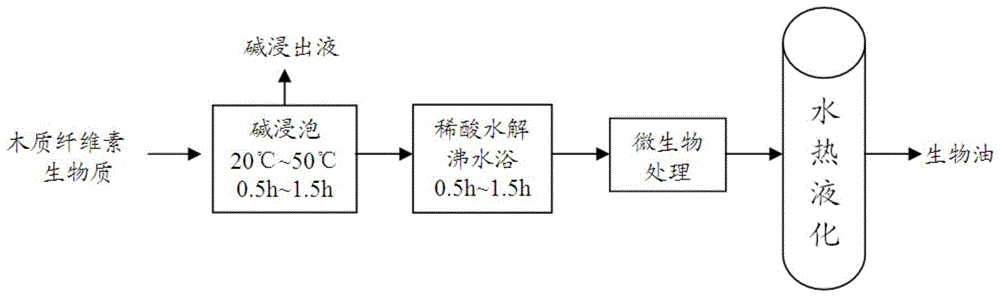

[0049] Example 1: Preparation of bio-oil by hydrothermal liquefaction of primary reactants of corn stalks

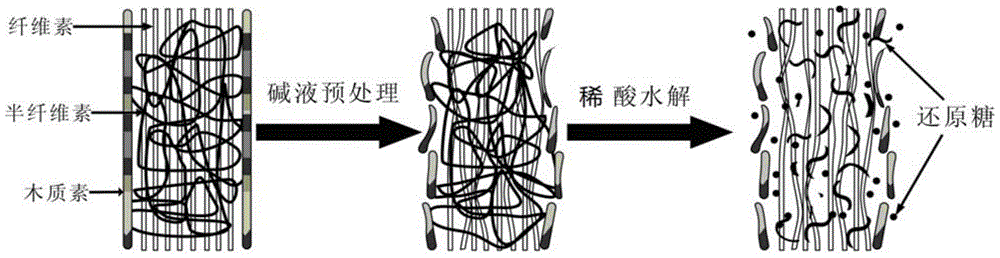

[0050] Collect fresh corn stalks, wash them, chop them, and weigh 30g (8.553g on a dry basis) and place them in a 250mL Erlenmeyer flask. Firstly, 2% NaOH solution is used to soak the raw material for 0.5 hour, so as to achieve the effect of destroying the lignin structure without dissolving the lignin too much. Then rinse the residue with deionized water to neutrality, tilt the mouth of the triangular flask until no water drips out, and define the state of the raw material at this time as: the primary reactant. After alkali treatment, the changes in the primary reactant components are shown in Table 1 below. Due to the destruction of lignin, a small decrease occurred, and the corresponding dry basis specific gravity of cellulose increased slightly.

[0051] Table 1

[0052] Types of

Cellulose%

Hemicellulose%

lignin%

Reducing sugar mg / mL

...

Embodiment 2

[0055] Embodiment 2: dilute acid pretreatment prepares bio-oil reactant

[0056] Prepare several parts of primary reactants in Example 1, add appropriate amount of 1%, 2%, 3% dilute H 2 SO 4 Solution (v / v), add the amount so that the primary reactant is enough to soak it. Hydrolyze in a boiling water bath for 0.5h, 1h, and 1.5h respectively, take it out after the hydrolysis ends, cool to room temperature, add an appropriate amount of NaOH to adjust the pH value to neutral, and all the substances (including water) obtained at this time are prepared by the method of the present invention Bio-oil reactants. The DNS method was used to detect the concentration of reducing sugar obtained under different dilute acid treatment conditions, and the detection results are shown in Table 2. Table 2 The reducing sugar concentration of primary reactants after dilute acid pretreatment under different conditions

[0057] Dilute acid concentration / %

Hydrolysis time / h

Reduci...

Embodiment 3

[0060] Embodiment 3: dilute acid concentration 1%, hydrolysis 1.5 hours reactant prepares bio-oil

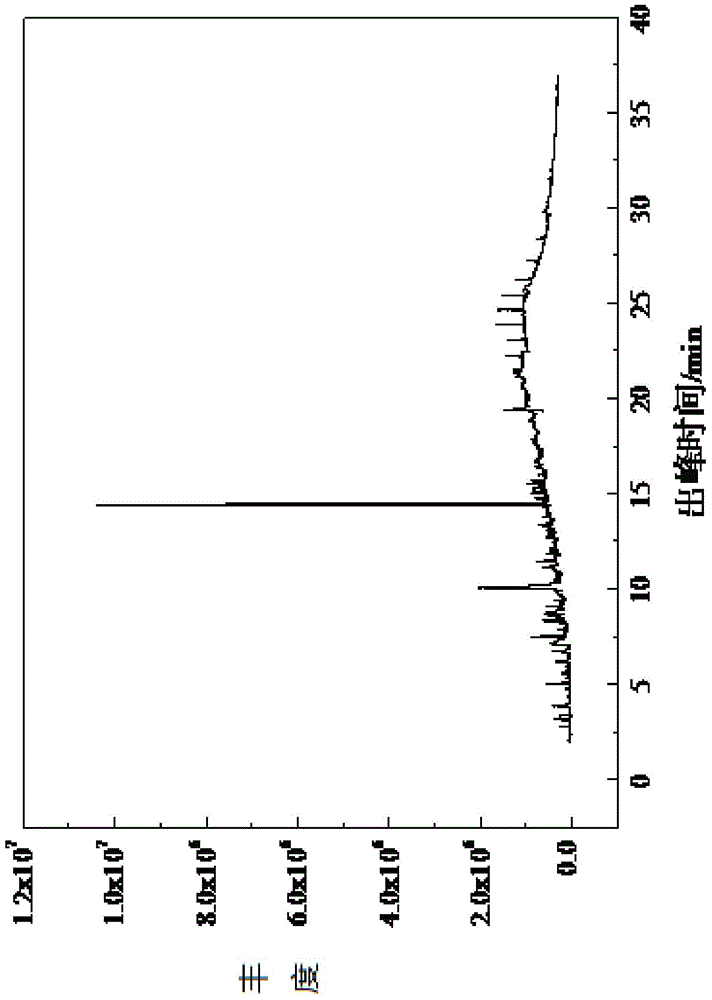

[0061] Also select the primary reactants in Example 1, add 150 mL of dilute sulfuric acid, the concentration of dilute sulfuric acid is 1%, and hydrolyze in a boiling water bath for 1.5 h. After the hydrolysis was finished, solid NaOH was added to adjust the pH value to be neutral. Add appropriate deionized water to adjust the total volume of solid and liquid in the Erlenmeyer flask to 200mL, then move it into the reaction kettle for hydrothermal liquefaction reaction, the reaction temperature is 370°C, and the reaction time is 30min. After the reaction, the bio-oil was extracted according to conventional methods. The mass of bio-oil was measured to be 3.2771g, and the volume of gas produced in the reaction was 0.389L. Further calculations obtained the liquefaction yield of bio-oil was 38.315%, the gas yield was 8.992%, and 75 substances were detected by bio-oil GC-MS , the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com