Method for promoting extraction of lignin in straw and catalytically preparing levulinic acid and ethyl ester thereof by using ammonium-based Brownst acidic ionic liquid

An acidic ionic liquid, catalytic preparation technology, applied in the direction of carboxylate preparation, carboxylate preparation, lignin derivatives, etc., can solve the problems of low yield of lignin extraction, complicated operation process, waste of resources and environment, and achieve Low cost, less dosage, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

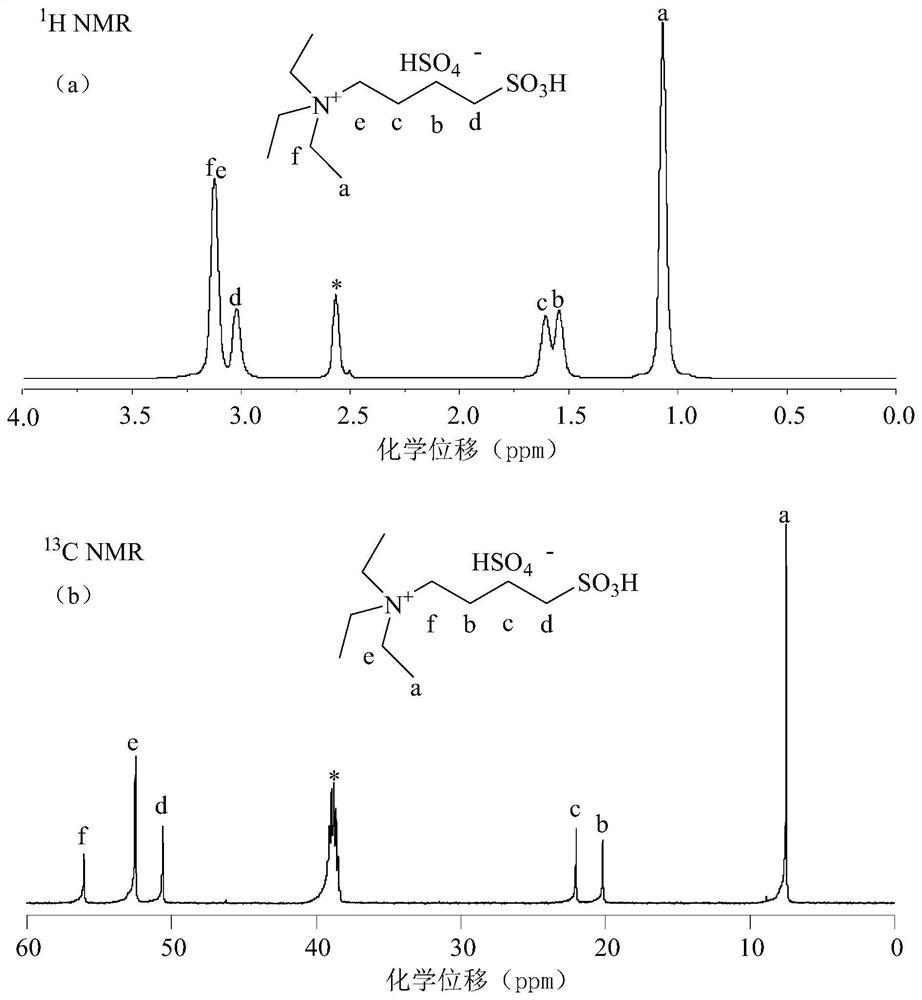

Method used

Image

Examples

Embodiment 1

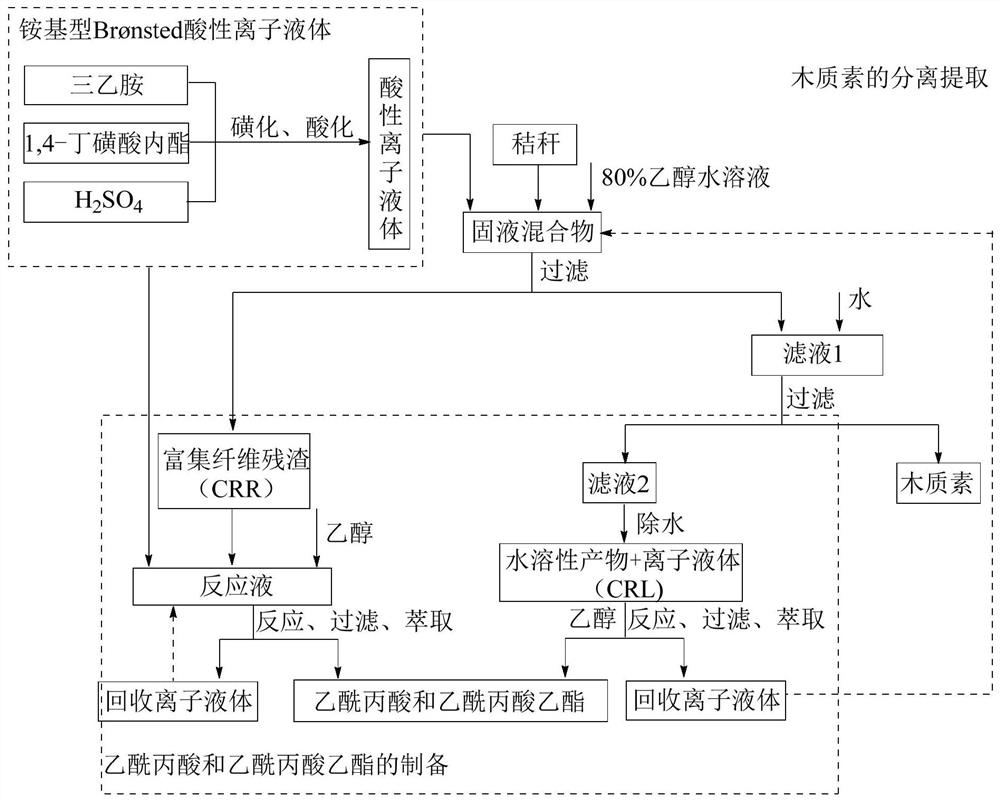

[0043] Such as figure 2 As shown, take 9g pretreated straw powder, 6mmol ammonium-based Acidic ionic liquid and 150mL aqueous ethanol (V C2H5OH / V H2O ; 4: 1) placed in the reaction kettle, fed with nitrogen protection, the initial pressure is 1MPa, the set speed is 300r / min, the reaction temperature is 200°C, and the reaction time is 30min. After the reaction, the reaction product is taken out, cooled to room temperature rapidly, and filtered 1. Wash (deionized water, 3×30mL), then add 500mL deionized water and let stand for 24h. Finally, the resulting mixture was filtered, washed, dried and ground to obtain a brown solid powder, ie lignin, which was sealed and stored in a dry place, and the yield of lignin was 23.73%.

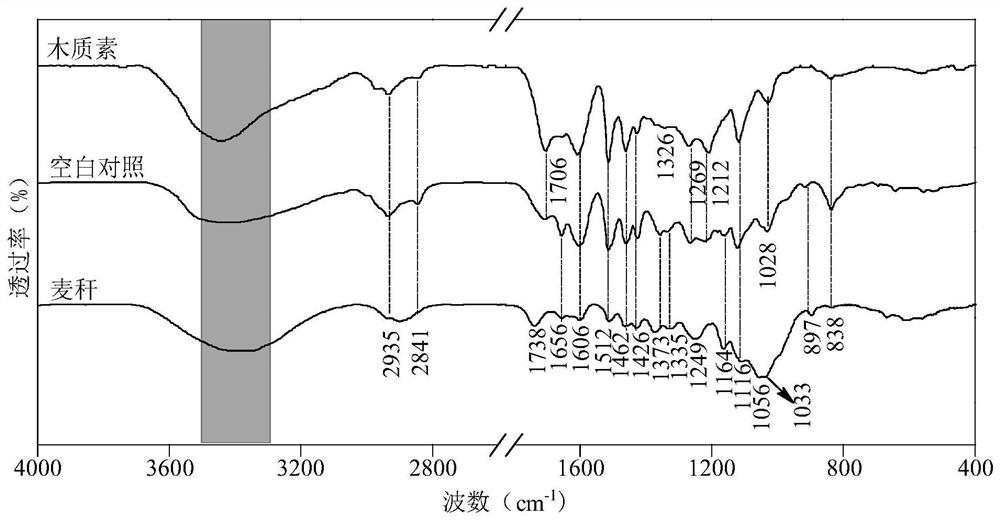

[0044] image 3 For pretreated straw, without adding ionic liquid and adding [BSTEA]HSO 4 Fourier transform infrared spectrum of extracted lignin (TEAILL). image 3 Medium 3450-3300cm -1 、2935cm -1 and 2841cm -1 The peak at is attributed to -OH, -O...

Embodiment 2

[0057] Such as figure 2 As shown, take 0.5g of the residue CRR of the rich fiber component obtained by filtering after the heating reaction in Example 1, 30wt.% (based on CRR) ammonium-based type Acidic ionic liquid and 20mL of absolute ethanol are placed in a reaction kettle, the rotation speed is set at 600r / min, the reaction temperature is 200°C, and the reaction time is 60min. Ethanol was removed by rotary evaporation and vacuum drying, the conversion rate of the residue was 9.78%, the yield of ethyl levulinate was 0.18%, and the process efficiency was 0.63%.

[0058] The waste liquid obtained after filtering the mixture obtained in Example 1 to remove lignin was subjected to vacuum rotary evaporation and vacuum drying to remove water to obtain a carbohydrate-rich liquid CRL, which was placed in a reaction kettle with 50mL of absolute ethanol, and the rotation speed was set at 600r / min, reaction temperature 200°C, reaction time 60min. After the reaction, the reaction pr...

Embodiment 3

[0066] The recovered ionic liquid [BSTEA]HSO 4 Dry overnight at 80°C, and then directly use it in the next lignin extraction reaction, the results are as follows Figure 6 shown. [BSTEA] HSO 4 After 5 cycles, the activity did not decrease significantly, and the yield of lignin was 19.90%, indicating that [BSTEA]HSO 4 better stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com