Building formwork system

A system and construction technology, applied in construction, building structure, on-site preparation of building components, etc., can solve the problems of formwork breakage and waste, easy for workers to step on unintentionally, troublesome formwork removal, etc., and achieve good toughness and light weight. , The construction effect is beautiful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

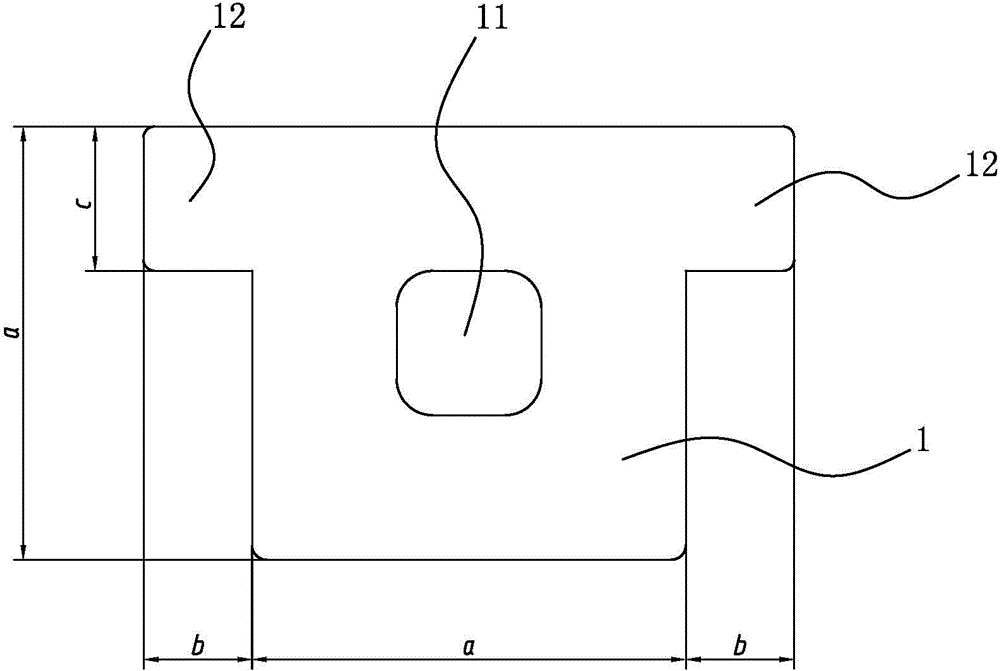

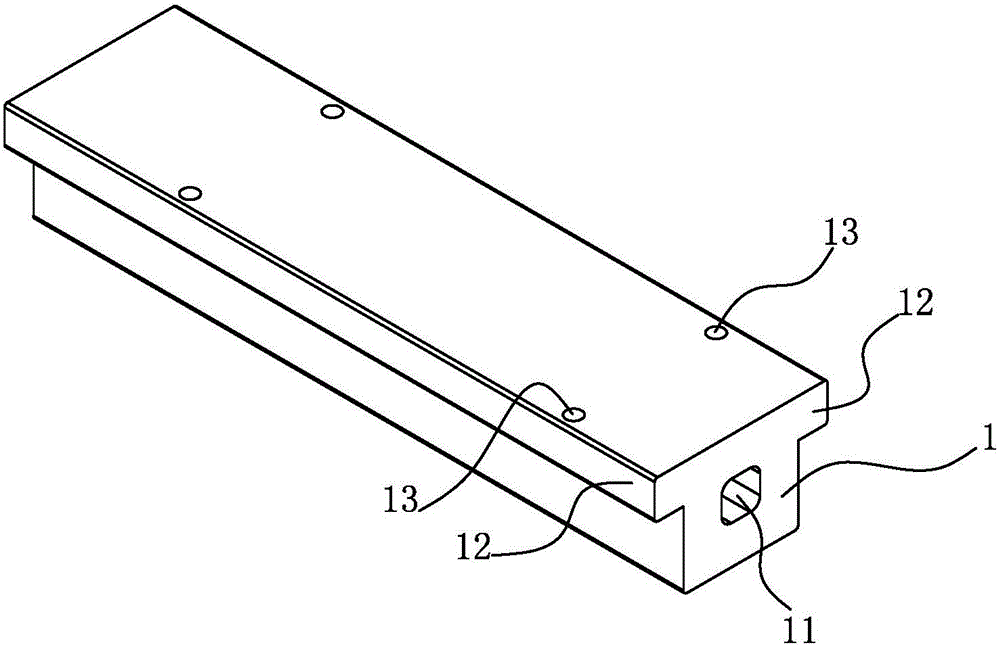

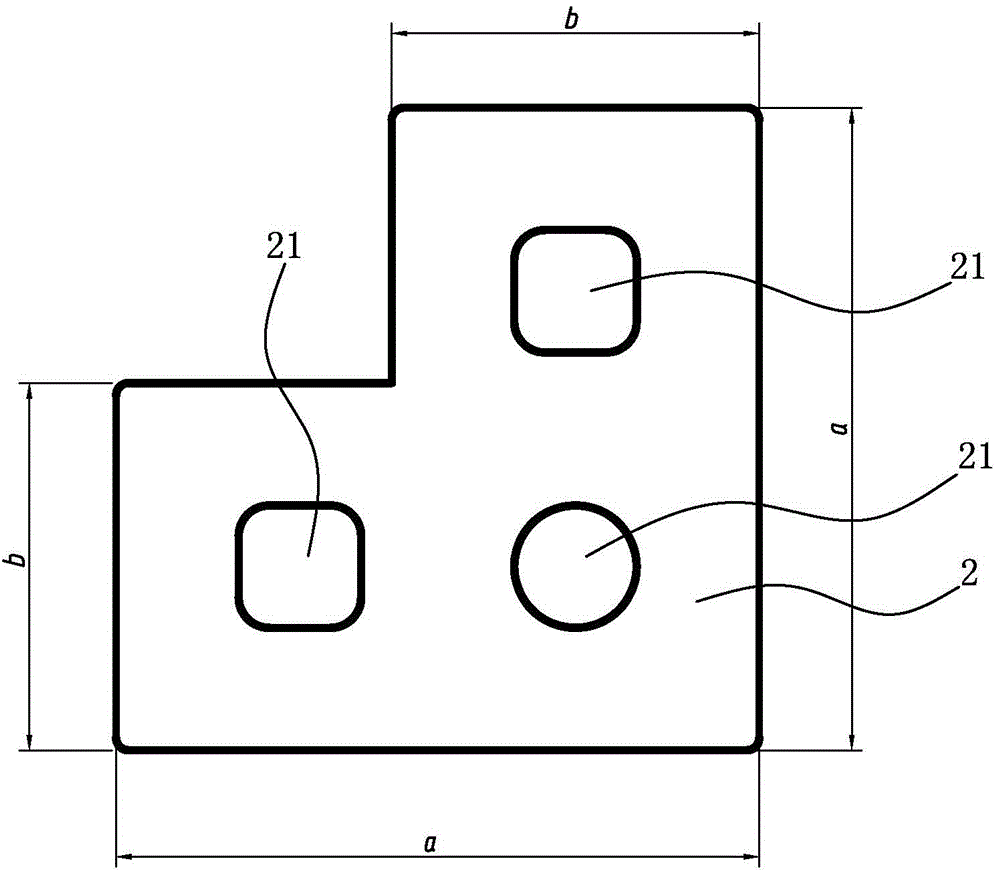

[0034] see Figure 1 to Figure 9 , a building formwork support system provided by the present invention, including a template and a support frame supporting the template, and also includes a hollow plastic planar support profile 1 with a T-shaped cross section and a hollow plastic corner support profile with an L-shaped cross-section 2. The plane support profile 1 and the corner support profile 2 are formed with heat dissipation and lightening holes 11, 21. The upper part of the plane support profile 1 extends to both sides to form a wing plate 12, and the wing plate 12 is formed with multiple A construction through hole 13, the planar support profile 1 is fixed on the plate surface of the template or connected to the adjacent template through the construction through hole 13, and the corner support profile 2 is supported on the adjacent said template corner of the template. The profile of the present invention has a long strip structure as a whole and is made of plastic. Sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com