Efficient environment-friendly and energy-saving gear overturning mechanism

An environmental protection, energy saving, and turning mechanism technology, applied in gear cutting machines, gear tooth manufacturing devices, belts/chains/gears, etc., can solve problems such as operator injury, affecting work safety, wasting productivity resources, etc. The effect of reducing occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

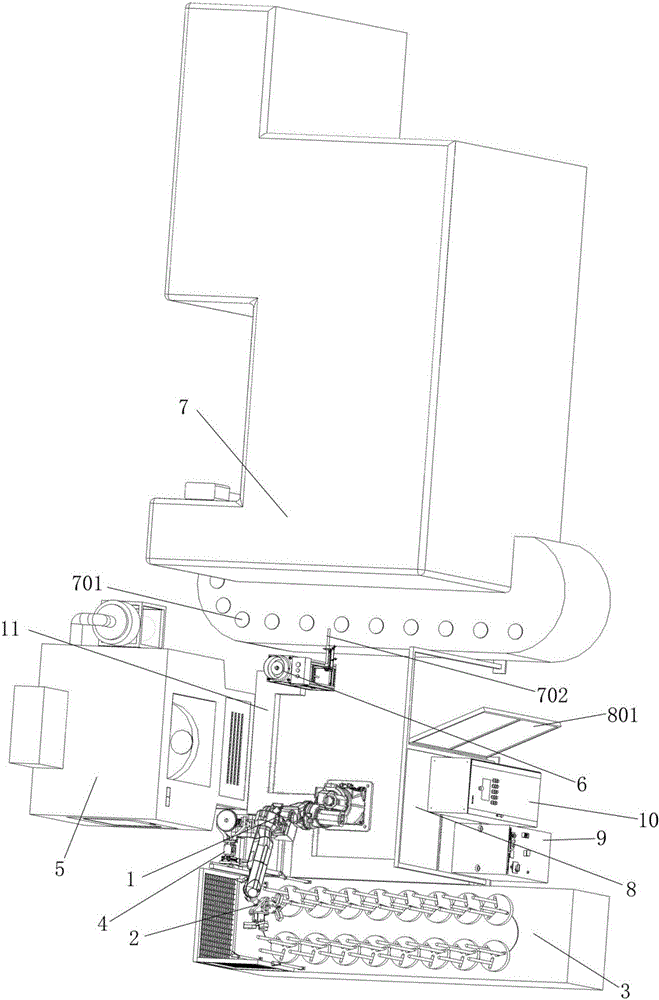

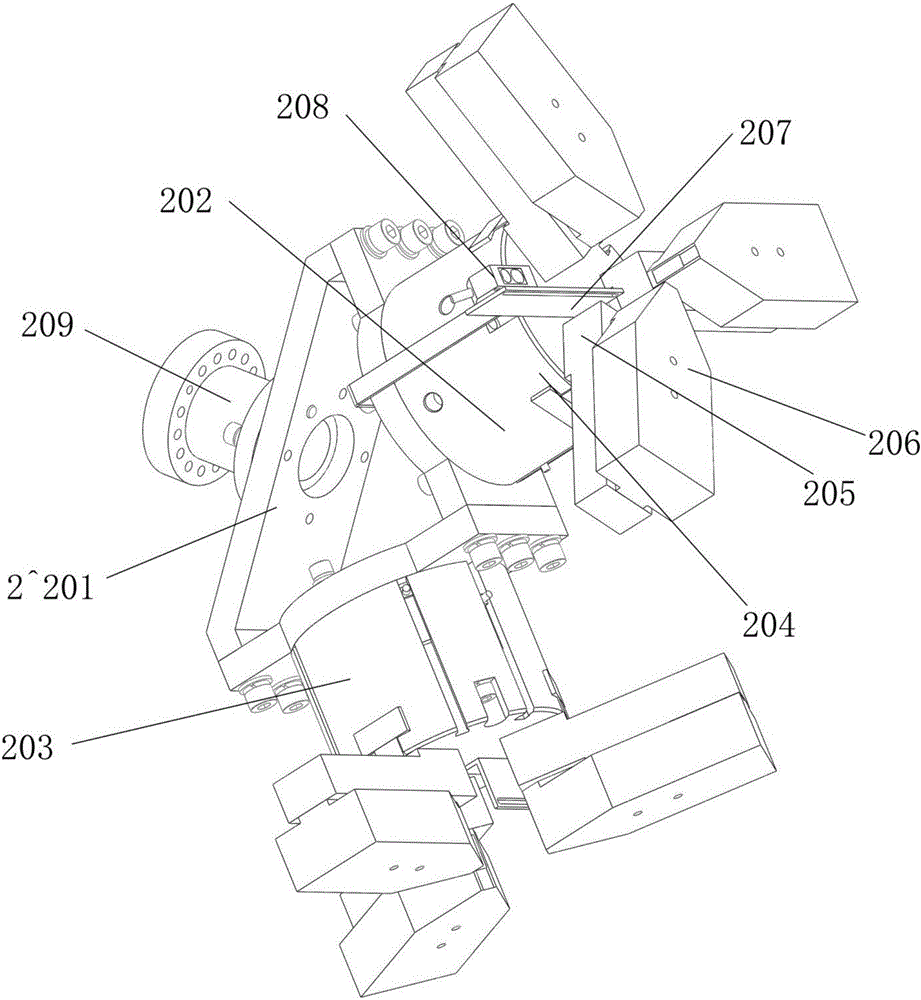

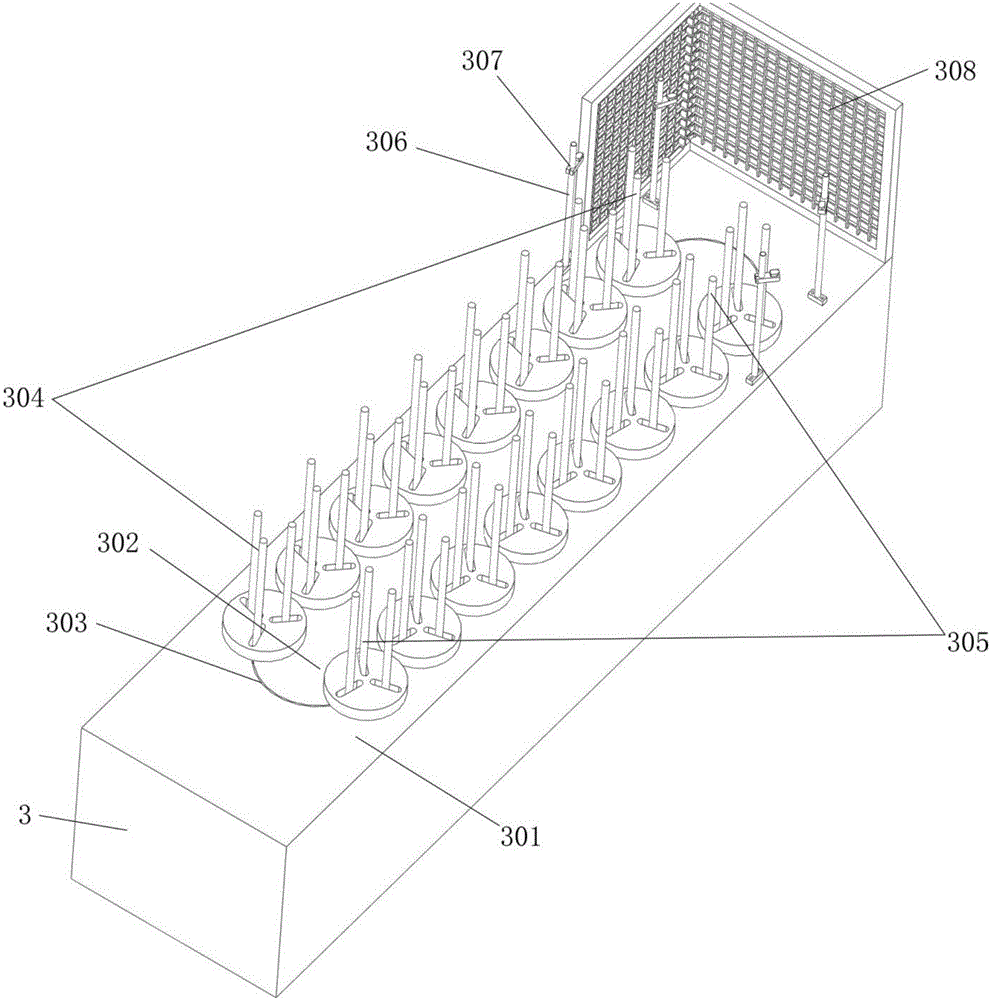

[0033] refer to Figure 1-Figure 7 , this embodiment provides a high-efficiency environmental protection gear hobbing processing conveyor line, including a manipulator 1 with a high-efficiency, environmental protection and energy-saving double-claw manipulator 2, a connecting wire slot 11 arranged around the manipulator 1, and respectively arranged in the connecting wire slot 11 The ones on the top correspond to the front, right and left sides of the manipulator 1 and are used in conjunction with the manipulator 1. The high-efficiency and low-noise gear loading and unloading mechanism 3, the high-efficiency and environmental protection fully enclosed gear cornering machine 5, and the transport platform provided on it 701 gear processing machine 7;

[0034] The semi-finished product positioning device 702 is arranged on the transportation table 701, and the high-efficiency environmental protection and energy-saving gear turning mechanism 4 used in conjunction with the manipulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com