Automatic material-fetching machine for clarifier case formed by stretching

An automatic reclaiming and filter technology, applied in the field of auto parts production equipment, can solve problems such as low efficiency, work-related accidents, and technical solutions have not yet been found, and achieve the effect of eliminating work-related accidents and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

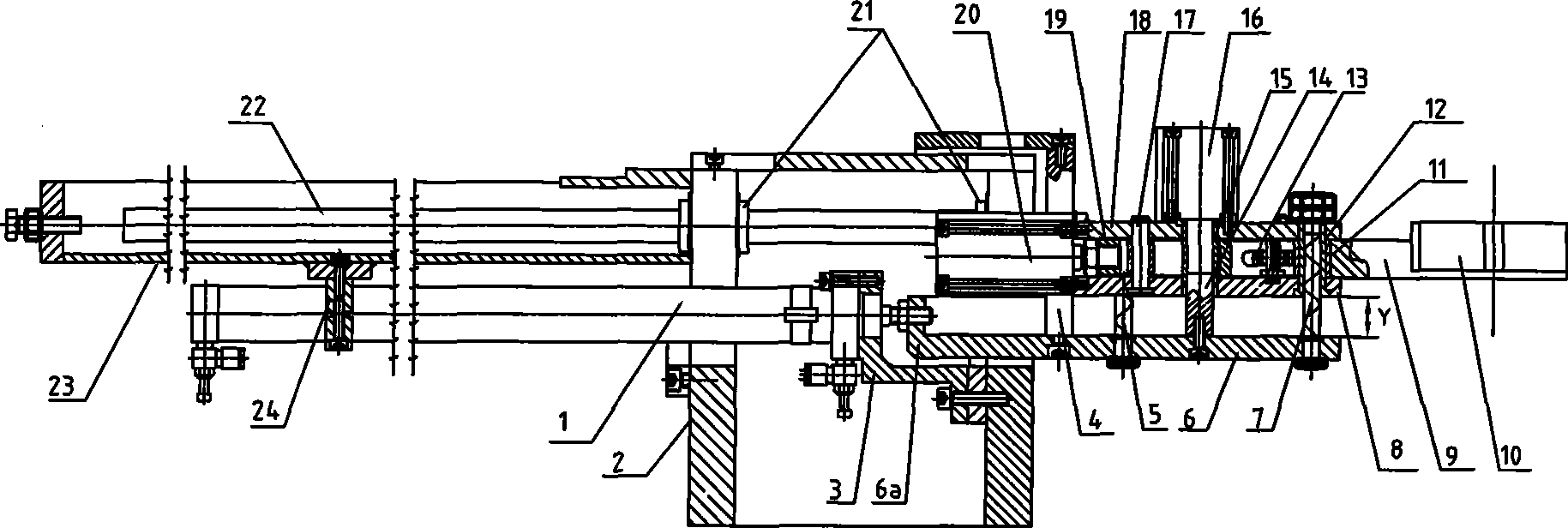

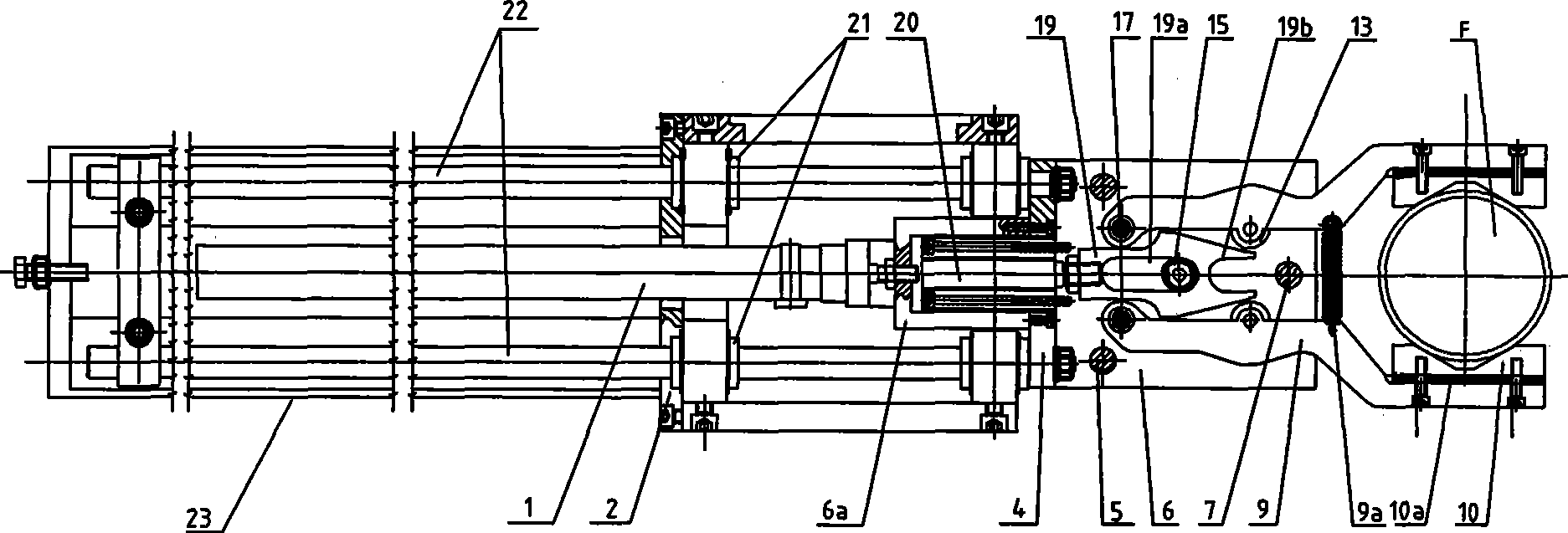

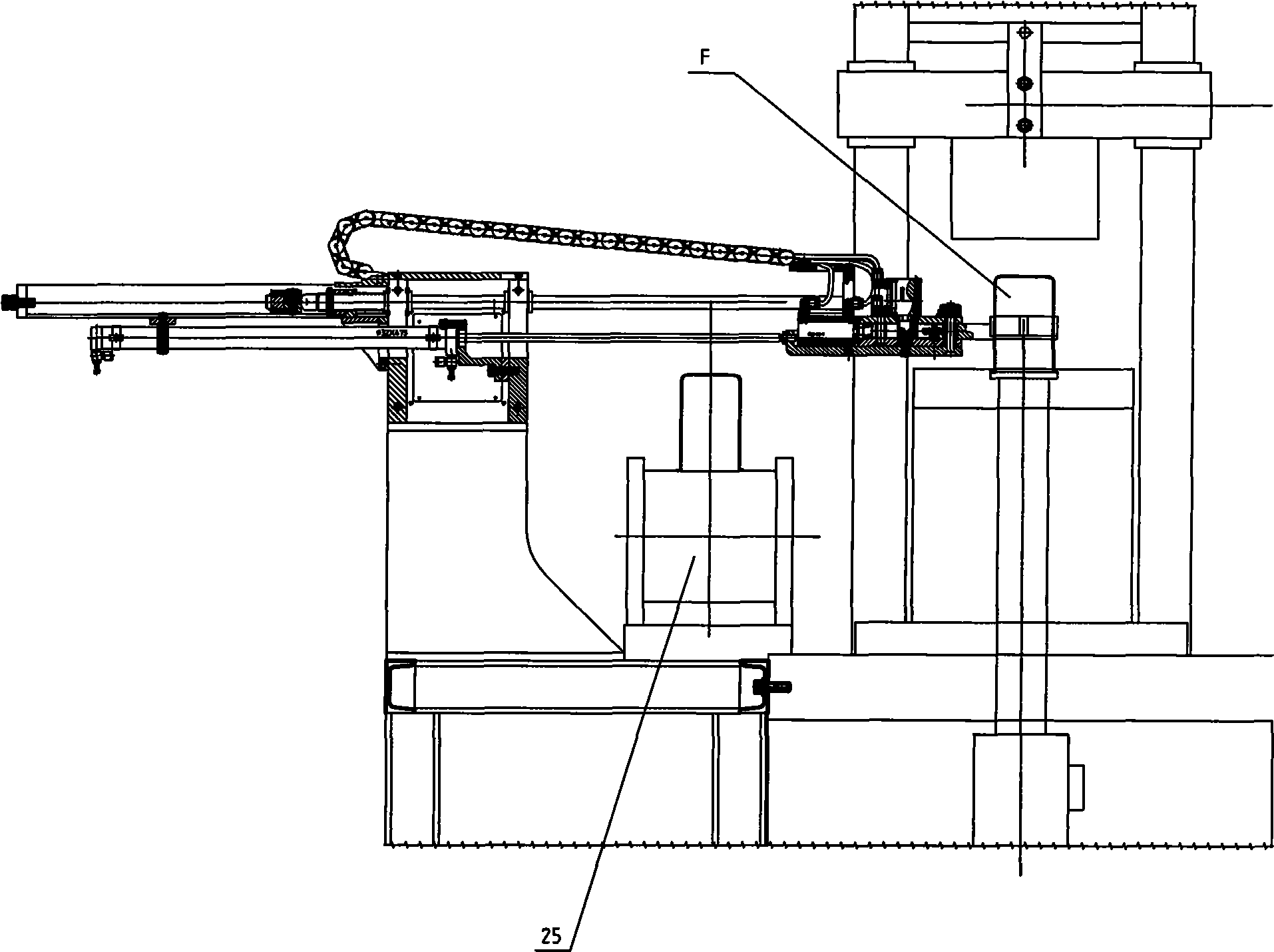

[0021] Such as figure 1 , figure 2 As shown, the filter shell stretching automatic reclaimer provided by the present invention mainly consists of the following components:

[0022] A. The base assembly is composed of a frame 2, two pairs of linear bearings 21 arranged on the frame 2, and a bracket 23 connected to one side of the frame 2.

[0023] B. The mechanical arm assembly is composed of arm cylinder 1, a pair of guide rods 22, and a hand support base plate 6. The right end of arm cylinder 1 is connected to the support 3 provided inside the frame 2, and the other end is connected to the bracket 23 below. On the support 24, two guide rods 22 are arranged on both sides correspondingly connected to the linear bearings 21 on both sides of the machine base and are in a sliding fit. The guide rods 22 can move horizontally in the bracket 23. The piston rod of arm cylinder 1 is connected on the raised frame 6a in the hand support base plate, and a vertical vertical plate 4 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com