Automatic stamping and conveying mechanism of duplex-glue black box threading hole

A technology of conveying mechanism and glue dark box, applied in metal processing and other directions, can solve the problems of poor processing accuracy, low production efficiency of manual operation, high labor cost and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

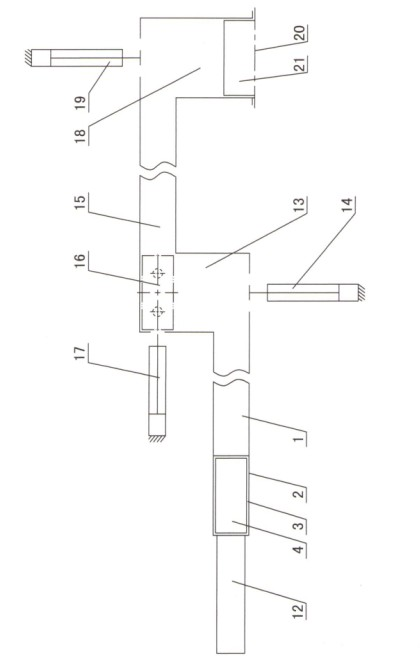

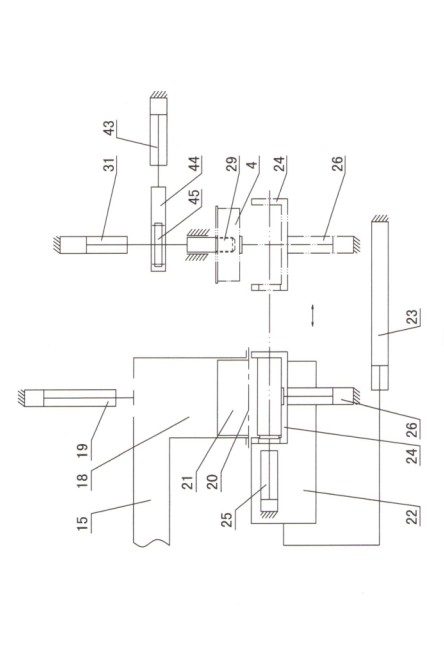

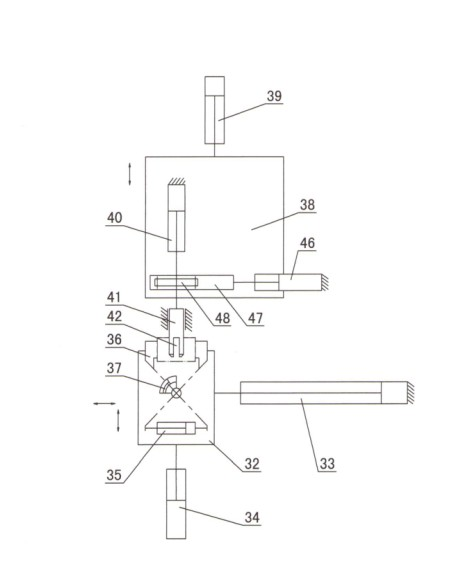

[0013] The invention relates to an automatic stamping and conveying mechanism for the threading hole of a duplex rubber dark box, such as Figure 1-Figure 6As shown, it is characterized in that it includes a punching bottom conveying device, a punching long board conveying device and a punching short board conveying device. The punching bottom conveying device includes a first horizontal groove 1 installed on the frame, and a feeder is installed on the front end of the first horizontal groove. Material support 2, feed opening 3 is arranged on the feeding support, and double-linked rubber dark box 4 is placed in the feeding mouth. There is a long plate 7, on the middle part of the bottom surface, there is an inserting plate 8 and a mounting column 9, and there is a threaded hole 10 in the mounting column, and a pushing cylinder A11 is installed under the first horizontal groove 1, and the piston rod of the pushing cylinder A is connected to the pushing plate 12. The push plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com