Stamping feeding device for circular workpieces

A circular workpiece and semi-circular technology, applied in the field of feeding devices, can solve the problems of high manual labor intensity, low production efficiency, hand injury accidents, etc., to avoid industrial accidents, improve processing efficiency, and increase stamping yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

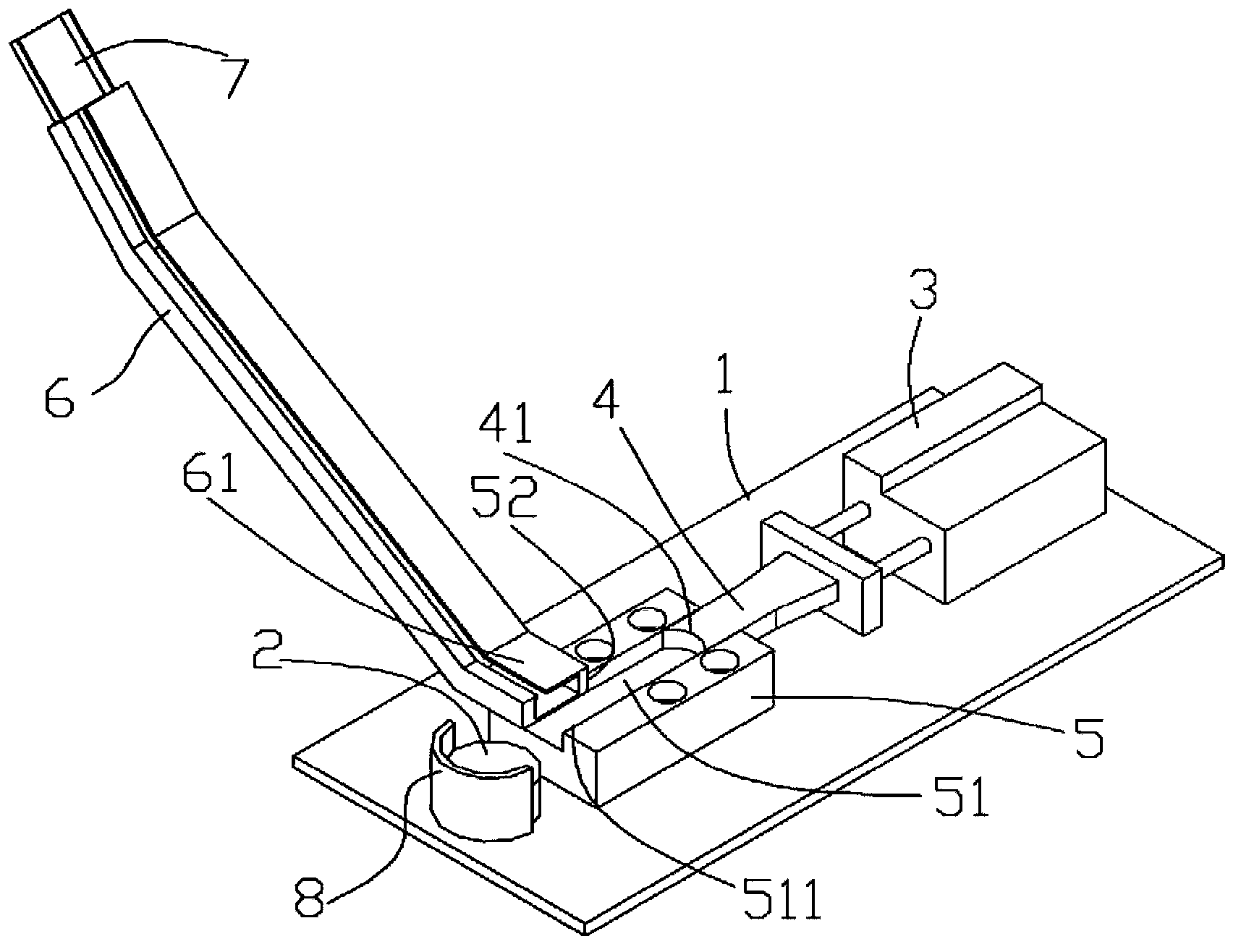

[0012] Example: see figure 1 As shown, the circular workpiece stamping and feeding device includes a punch table 1, on which a stamping lower die 2 is fixed, a push cylinder 3 is fixed on the punch table 1, and a push plate 4 is fixed on the push cylinder On the piston rod of 3, a through groove 51 and a gap 52 are formed on the square block 5, the outlet of the material channel 6 is connected with the through groove 51, and the push plate 4 is inserted and sleeved in the through groove 51;

[0013] The stamping lower die 2 is fixed with a semicircular baffle 8, the front end of the push plate 4 is formed with a semicircular jaw 41, and the upper surface of the stamping lower die 2 and the bottom surface of the through groove 51 are located on the same plane.

[0014] A feeding frame-shaped guide plate 7 is fixed on the forehearth 6 , the discharge section 61 of the forehearth 6 is parallel to the plane of the punch table 1 , and the discharge section 61 is fixed at the gap 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com