Multi-shaft horizontal joint intelligent robot

An intelligent robot, horizontal joint technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of inaccurate movement and positioning of robots or manipulators, large stroke and moving range of grasping weight, complex calculation program control response delay, etc. , to achieve the effect of reducing labor intensity, improving work rhythm, and avoiding work-related accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

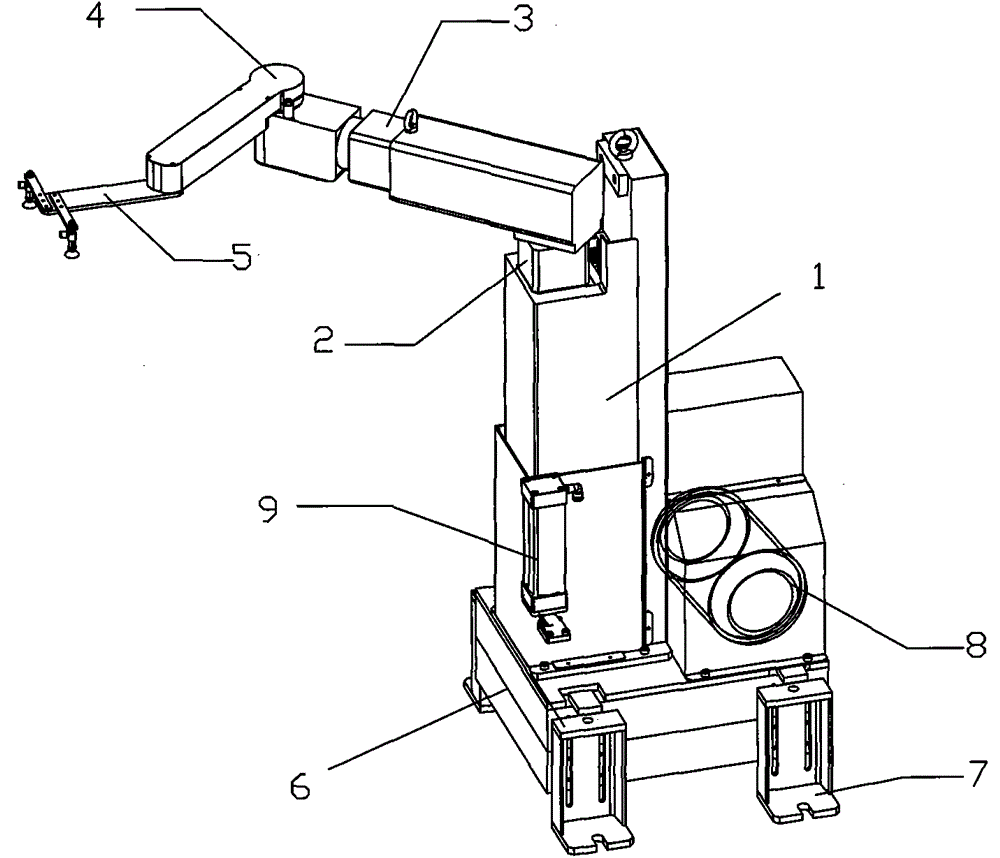

[0020] Such as figure 1 As shown, the present invention provides a multi-axis horizontal joint intelligent robot. This embodiment is a four-axis horizontal joint intelligent robot, including an intelligent control manipulator. The intelligent control manipulator is composed of a control device, an actuator, a driving device and a base; The actuator includes a first shaft 1 for up and down motion control, and three second shafts 2, third shaft 3, and fourth shaft 4 for horizontal motion control; the driving device includes a first shaft servo motor, the second axis absolute value servo motor, the third axis absolute value servo motor, the fourth axis absolute value servo motor and the transmission device (because the servo motor and the transmission device are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com