Edging full-automatic feeding and discharging machine

A fully automatic, feeding machine technology, applied in the direction of grinding feed movement, grinding machine parts, machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of slow working rhythm and achieve the improvement of working rhythm and utilization High efficiency and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

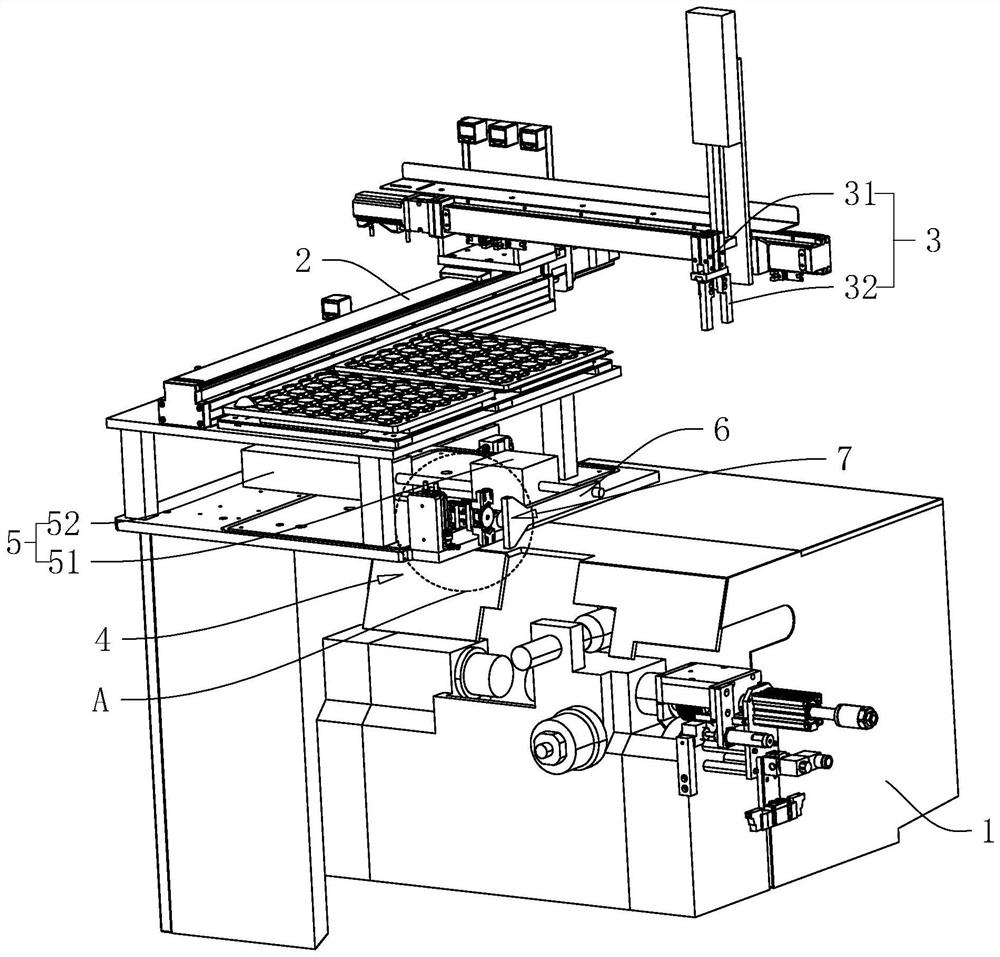

[0042] Embodiment 1, with reference to figure 1 , the core-taking automatic loading and unloading machine includes a frame 1, an XYZ three-axis slide 2 and a first pick-up part 3, the XYZ three-axis slide 2 is fixedly connected to the frame 1, and the first pick-up part 3 is fixedly connected On the XYZ three-axis slide table 2, so that itself can move on the horizontal plane and the vertical plane, specifically, the first pick-up part 3 includes a first jaw cylinder 31 and two first clamping blocks 32, the first The jaw cylinder 31 is fixedly connected to the XYZ three-axis slide table 2, and the output end of the first jaw cylinder 31 faces downward, and the two first clamping blocks 32 are respectively fixedly connected to the two sides of the first jaw cylinder 31. On the output side to be able to clamp the workpiece.

[0043] refer to figure 1 , in this embodiment, the workpiece is an optical lens in the shape of a disc, wherein the optical lens is placed in the storage...

Embodiment 2

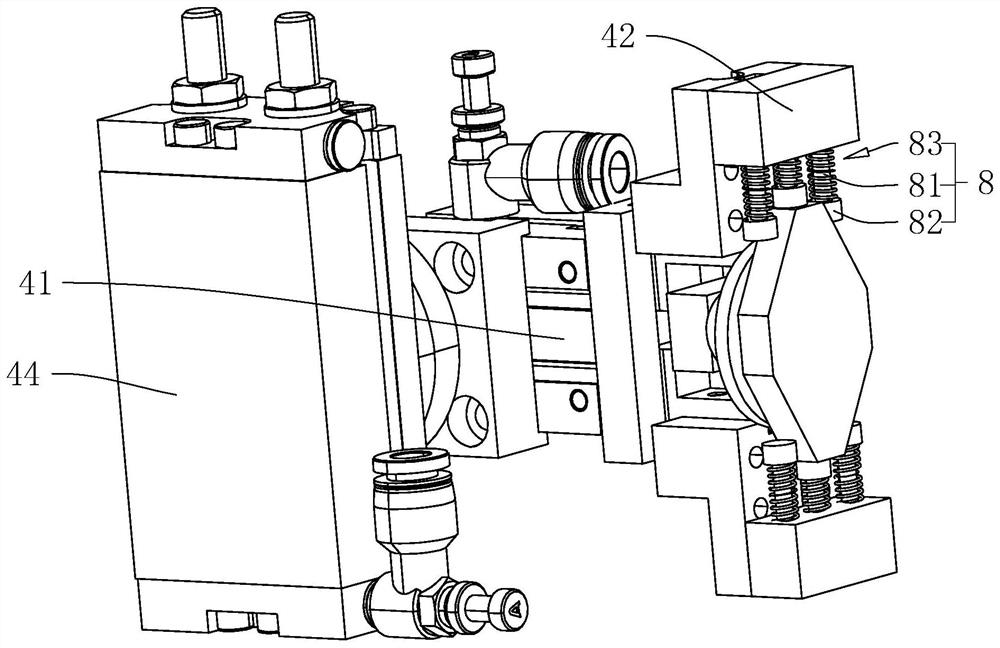

[0059] Embodiment 2, with reference to image 3 , the difference from Embodiment 1 is that an auxiliary clamping member 8 is provided on the ends of the two second clamping blocks 42 that are close to each other, and the auxiliary clamping member 8 includes a sliding rod 81, an elastic block 82 and a spring 83, wherein One end of the sliding rod 81 slides through the second clamping block 42, and the length direction of the sliding rod 81 is parallel to the line direction between the two second clamping blocks 42, and the sliding rod 81 is perpendicular to the direction of the two second clamping blocks 42. The direction of motion of the two clamping blocks 42 is evenly distributed with a plurality; the elastic block 82 is a deformable silicone material, and the elastic block 82 is fixedly connected to the end of the slide bar 81 away from the second clamping block 42; the spring 83 Then, it is sleeved on the exposed part of the sliding rod 81 outside the second clamping block...

Embodiment 3

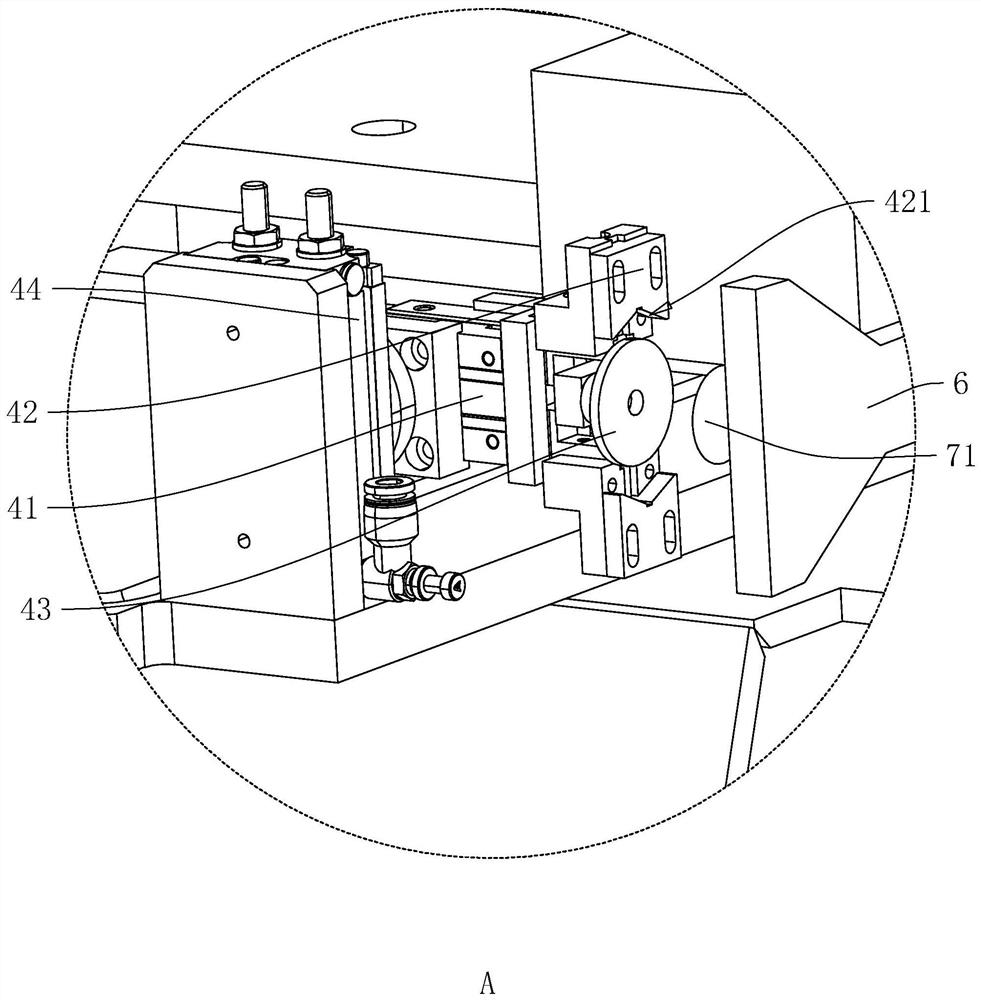

[0061] Embodiment 3, with reference to figure 2 and Figure 4 , the difference from Embodiment 1 is that the vacuum chuck 71 includes a fixed chuck 711 and two sliding chucks 712, wherein the fixed chuck 711 is fixedly connected to the swing rod 6, and the fixed chuck 711 can abut against the optical axis of the workpiece The sliding suction cup 712 is slidably connected on the fork 6, and the two sliding suction cups 712 are arranged symmetrically with respect to the fixed suction cup 711, and the two sliding suction cups 712 can slide towards the direction of approaching or moving away from each other. In addition, in this embodiment, the swinging suction cup The rod 6 is also provided with an element capable of communicating with the sliding suction cup 712 through an air path.

[0062] refer to figure 2 and Figure 4 The part of the swing rod 6 close to the vacuum suction cup 71 has an installation cavity 61 and a fixed passage 62 communicating with the installation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com