An automatic screw-tightening device

A screw-tightening and automatic technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems that affect the efficiency of object combination, complex equipment structure, and low work efficiency, so as to achieve flexible switching of space positions, reduce cumbersomeness, and cost little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

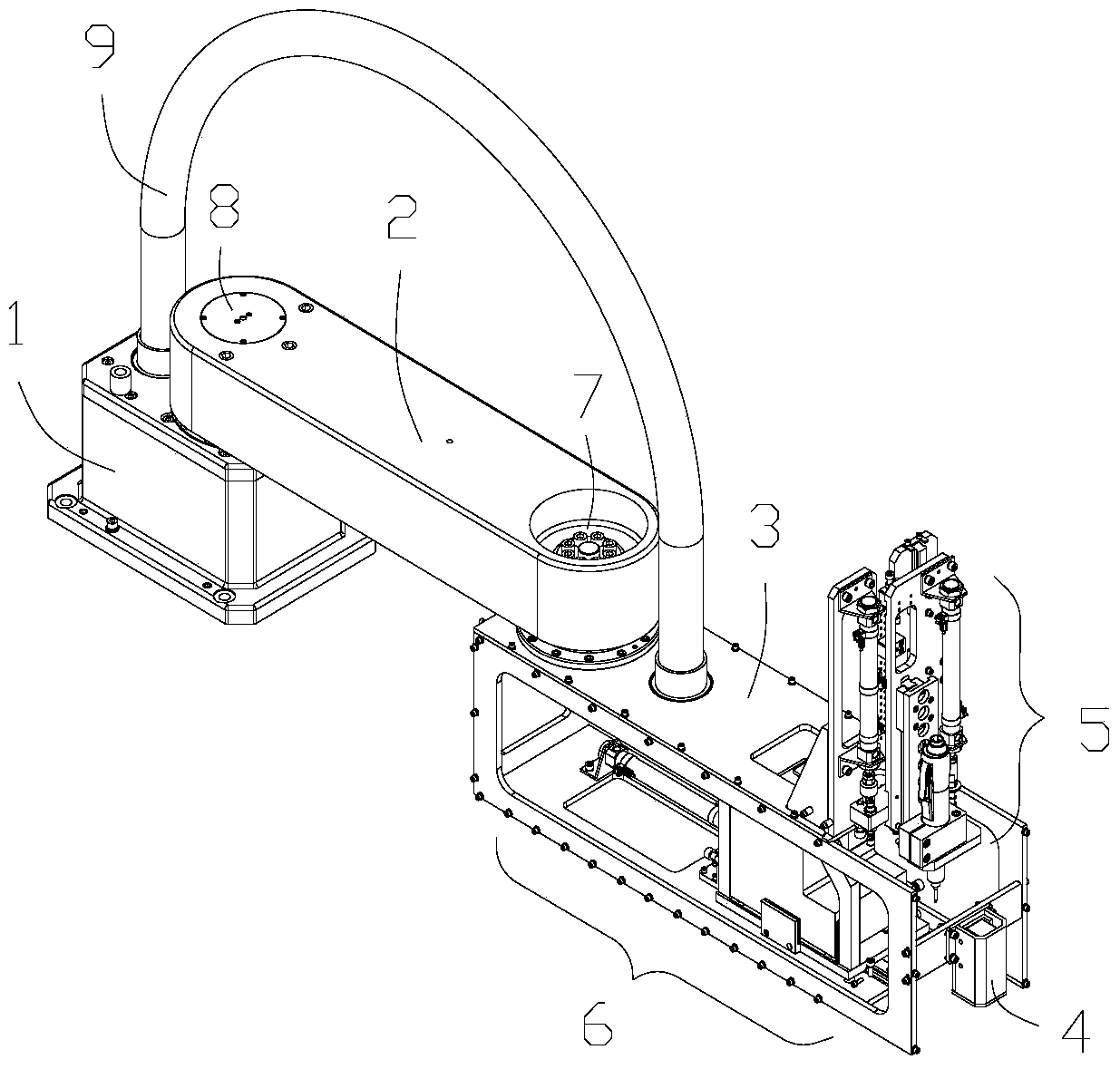

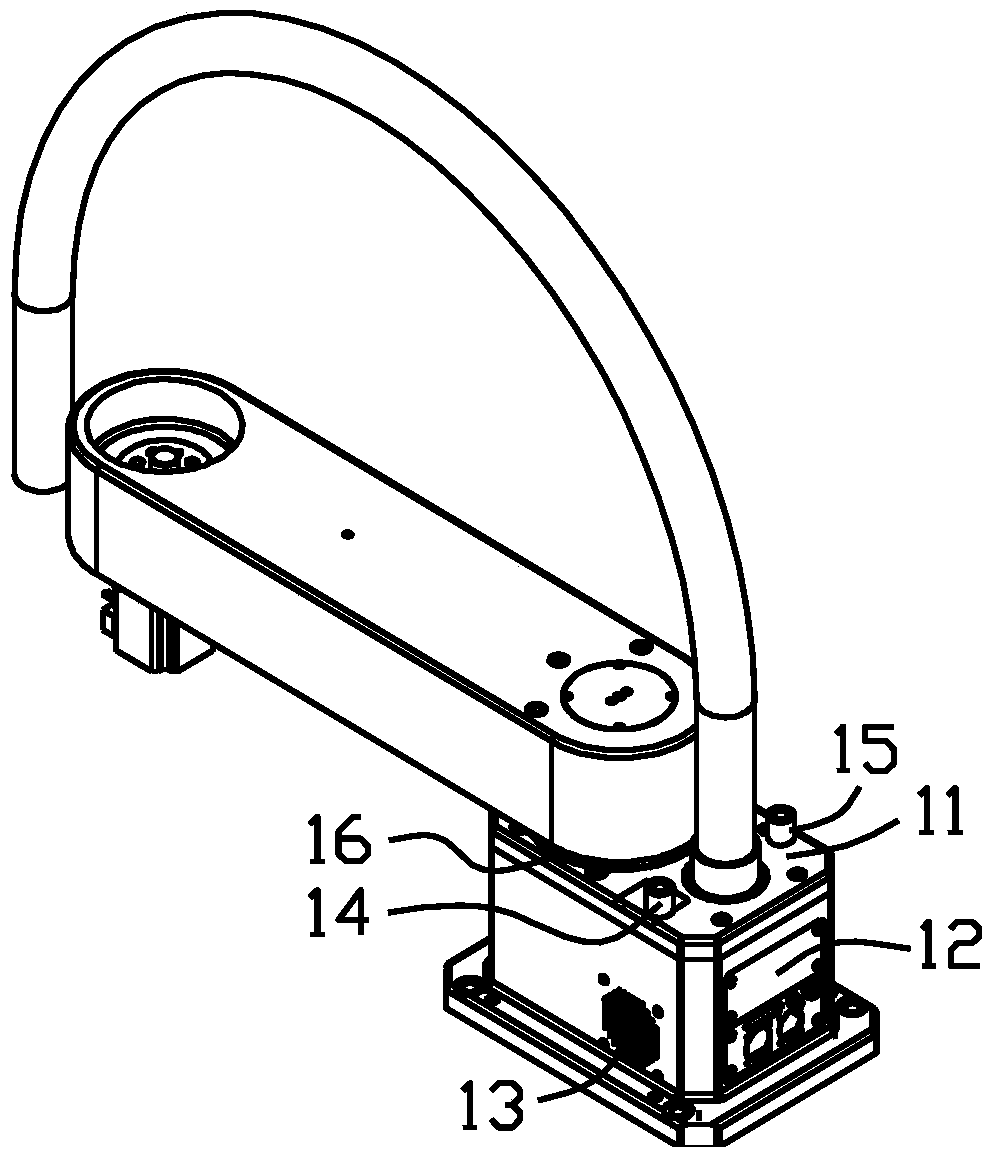

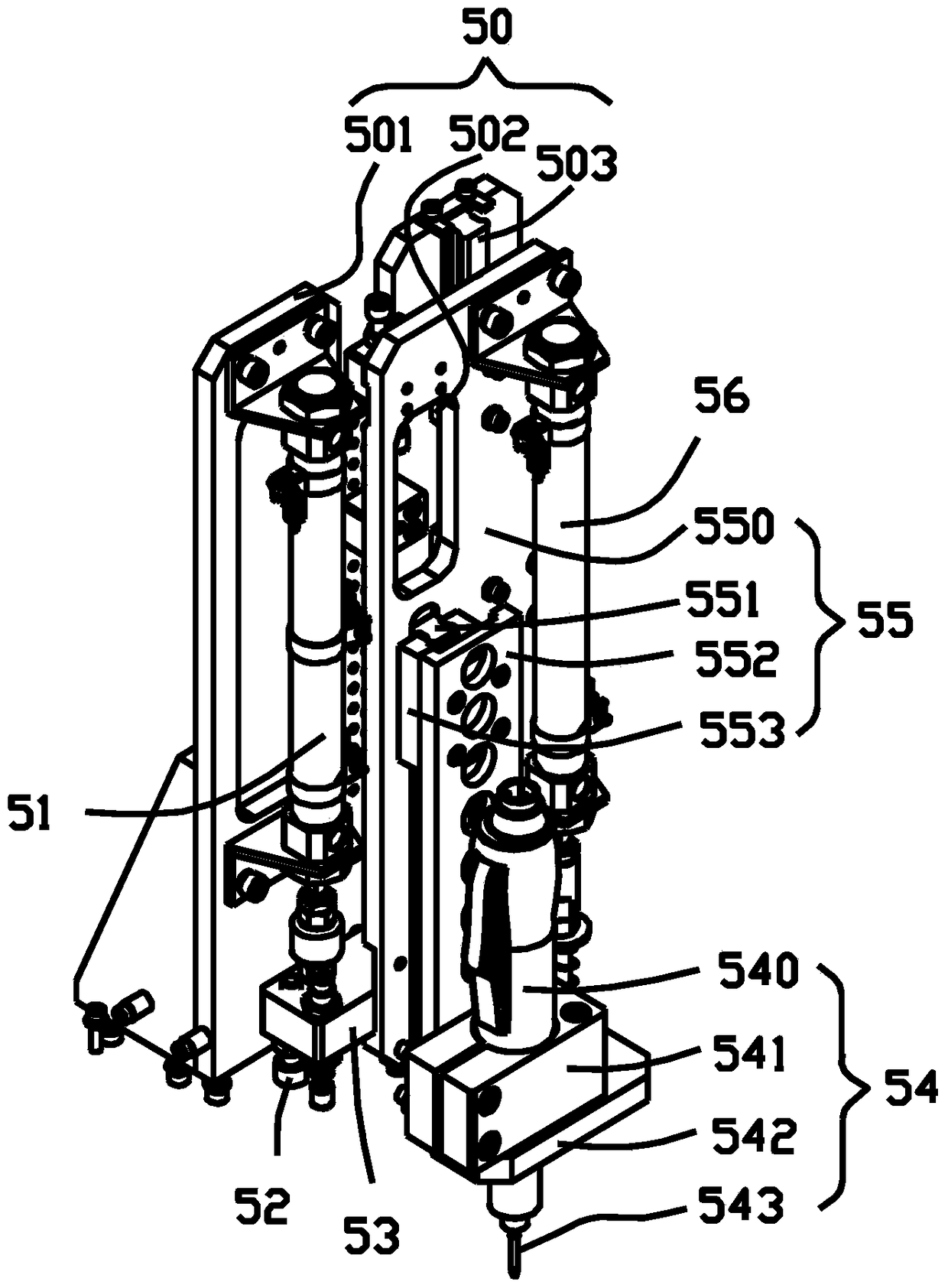

[0022] Such as Figure 1-7 As shown, an automatic screwing device includes a base 1, a boom 2 and a forearm 3, the upper end of the base 1 is provided with a boom 2, and the front end of the boom 2 is connected with the forearm 3; in order to increase the working coverage area, the base 1 and the forearm 3 The connection between the boom 2, the boom 2 and the forearm 3 is realized through the flexibility of the second motor 8 and the first motor 7 respectively, wherein the forearm 3 can rotate around the boom 2, and the boom 2 can rotate around the base 1, There is a wiring hose 9 between the base 1 and the forearm 3, the lower end of the forearm 3 is provided with a nail feeding mechanism 6, the upper end of the forearm 3 is provided with a nailing mechanism 5, and the front end of the nailing mechanism is provided with a visual camera 4, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com