Carrying device

A technology for handling devices and materials, which is applied in the field of material handling, palletizing, and automatic control, and can solve problems such as long matching beats, poor paper laying flatness, and large equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to be able to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

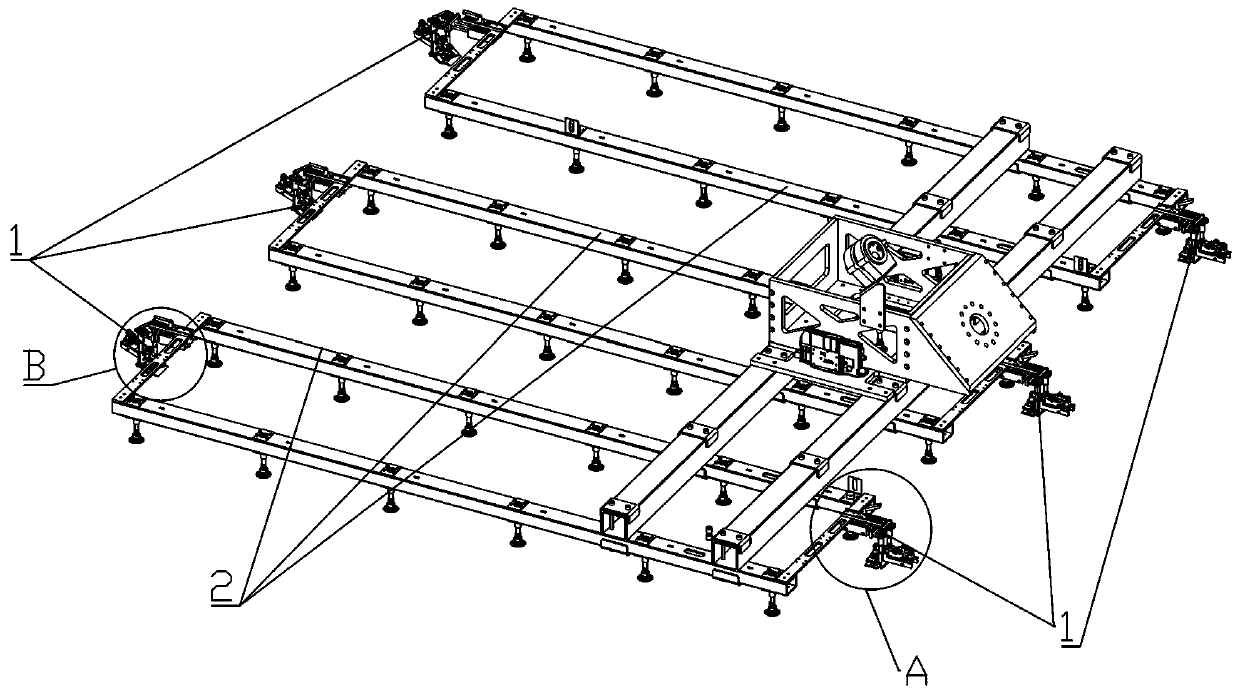

[0061] Such as Figure 1 to 6 As shown, the handling device in this embodiment includes:

[0062] Material grab module, used to grab materials;

[0063] The cushion grasping module 1 is arranged on the edge of the material grasping module, and is used for grasping the cushion located below the material when the material grasping module grasps the material .

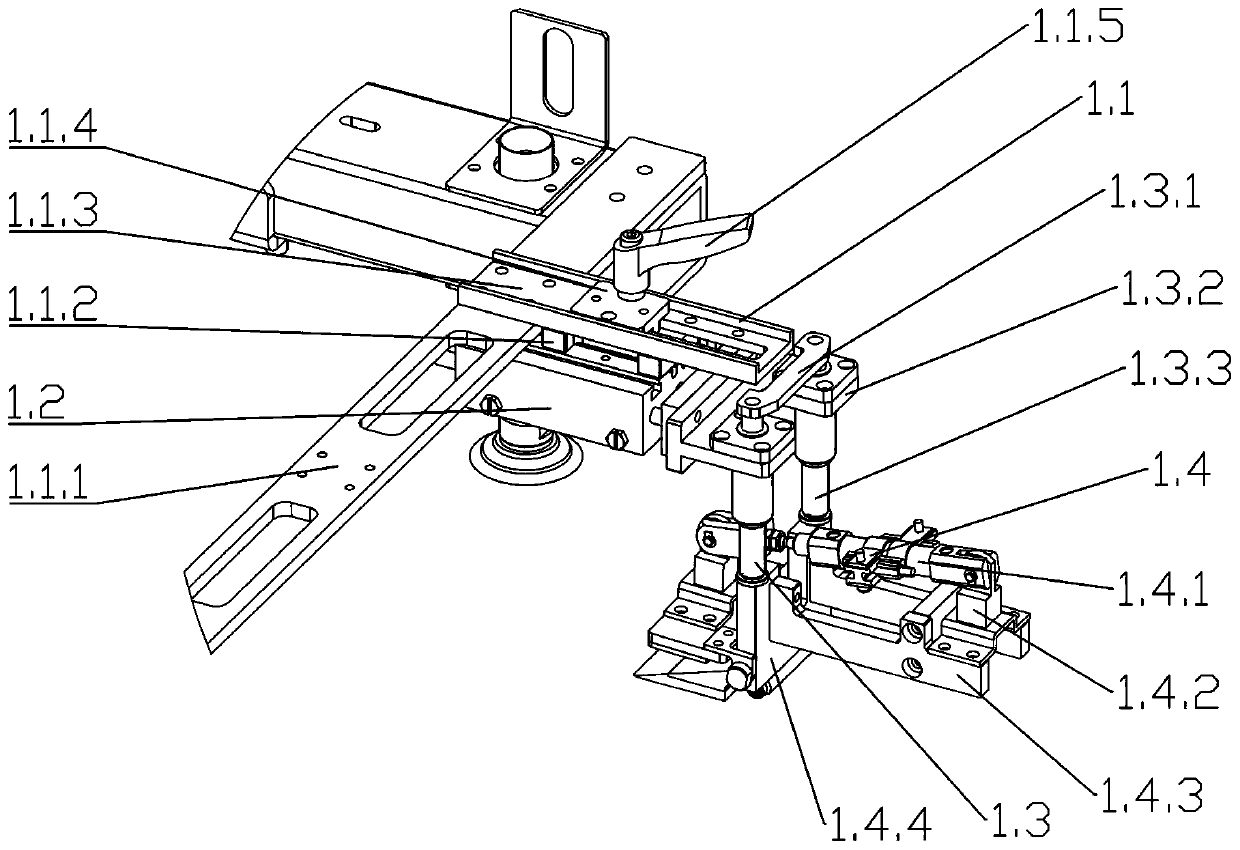

[0064] In this embodiment, the cushion grabbing module 1 includes an array of clamping components 1.4, and the plurality of clamping components 1.4 are distributed on both sides of the material grabbing module, and each group of the clamping components 1.4 The clamping components 1.4 are all fixed to the edge of the material grabbing module through a corresponding fixed support beam component 1.1.

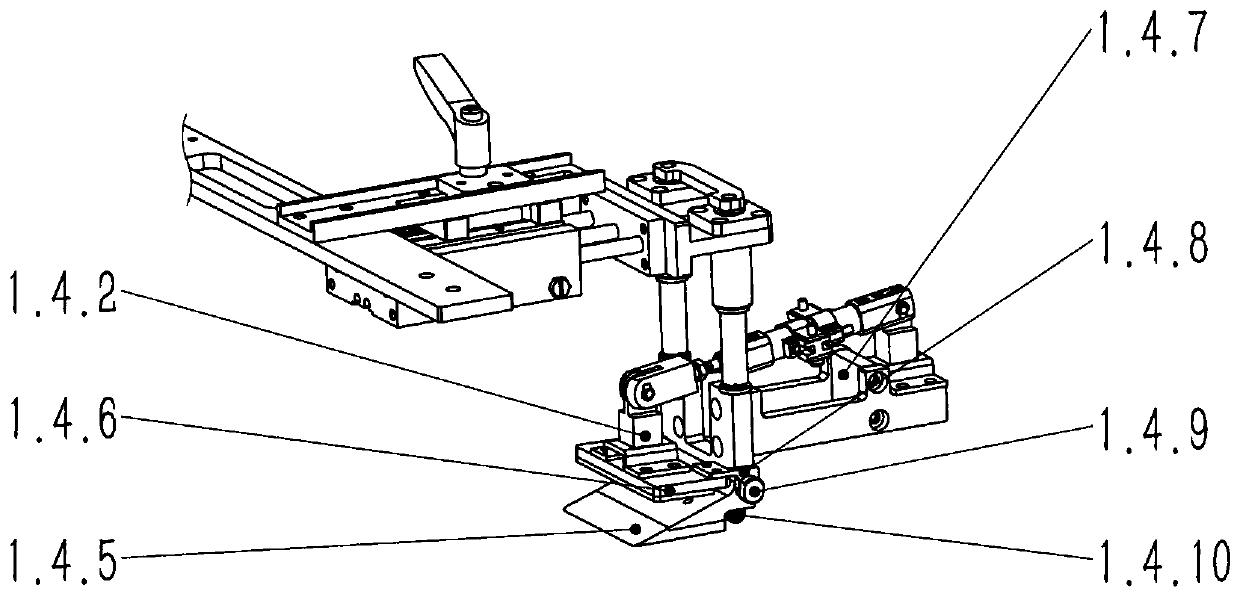

[0065] In this embodiment, the clamping assembly 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com