Discharging device of cold-pressing sealing-head hydraulic machine

A technology for hydraulic presses and heads, which is applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., and can solve problems such as low production efficiency, different head materials, and large frame spans and other issues to achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

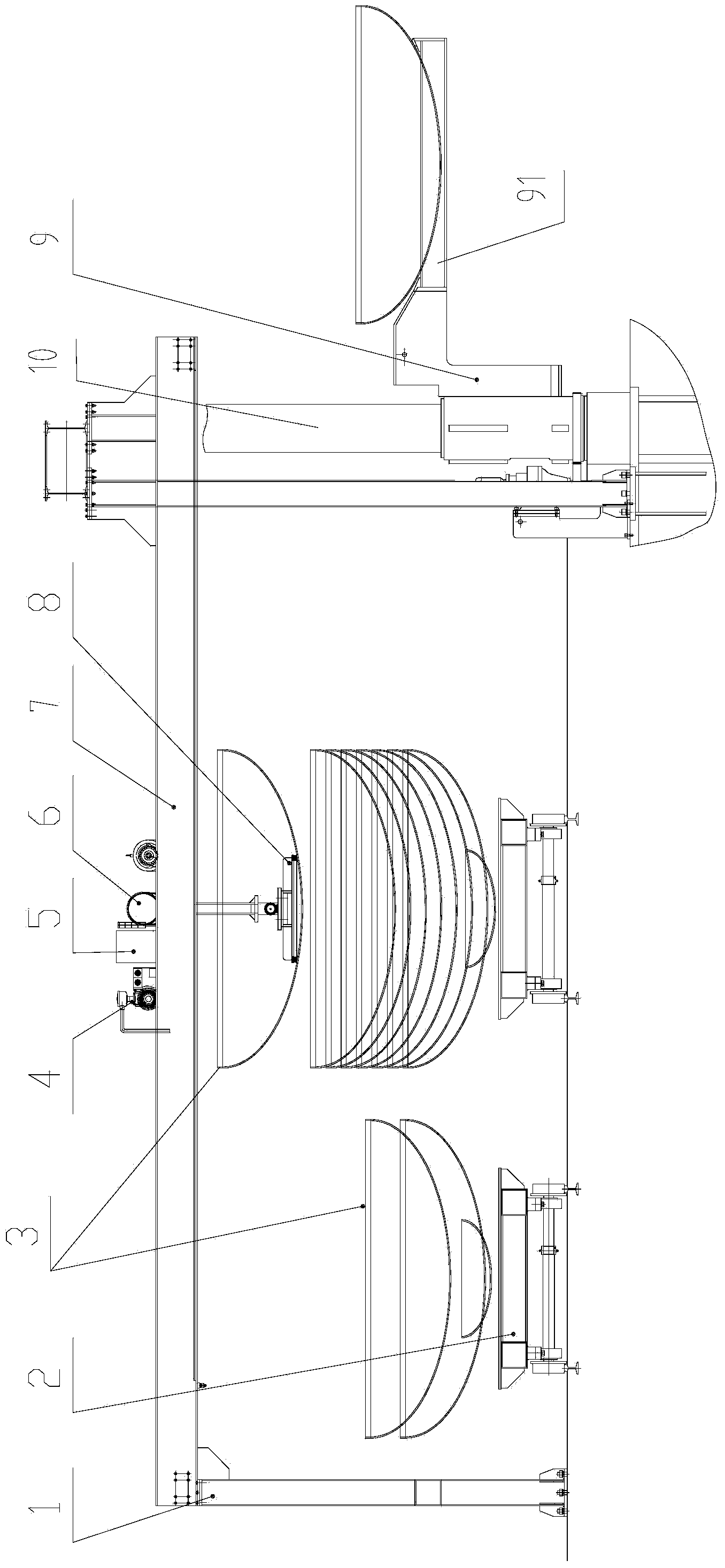

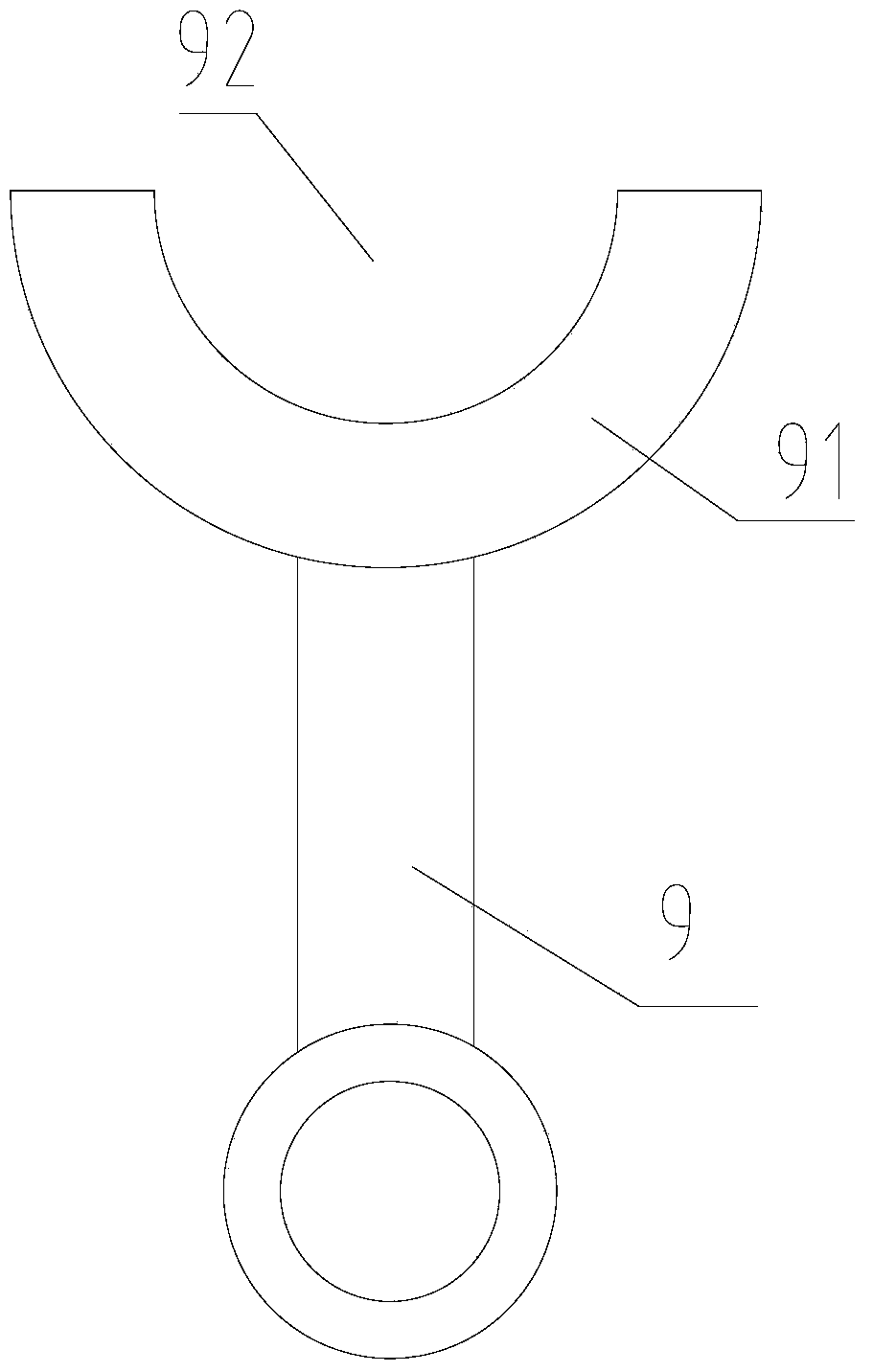

[0016] see figure 1 , figure 2 , a blanking device for a cold-pressed head hydraulic press provided by the present invention includes a frame 1 and a delivery beam 7 arranged on the frame 1, and the delivery beam 7 is arranged below the delivery beam 7 in sequence along the length direction of the delivery beam 7. Station and stacking station, the stacking station includes a conveying trolley 2, a sliding seat is installed on the conveying beam 7, and a vacuum suction cup 8 that can move up and down is installed on the sliding seat. The up and down movement of the vacuum suction cup 8 is determined by the The li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com