Mould-repair replacing equipment for electrode caps of welding machine

A technology for replacing equipment and electrode caps, applied in welding equipment, resistance welding equipment, electrode maintenance, etc., can solve the problems of decreased welding quality, easy wear and tear of electrode caps, and the inability of electrode caps to meet the requirements of mass production. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in detail below in conjunction with the drawings and embodiments.

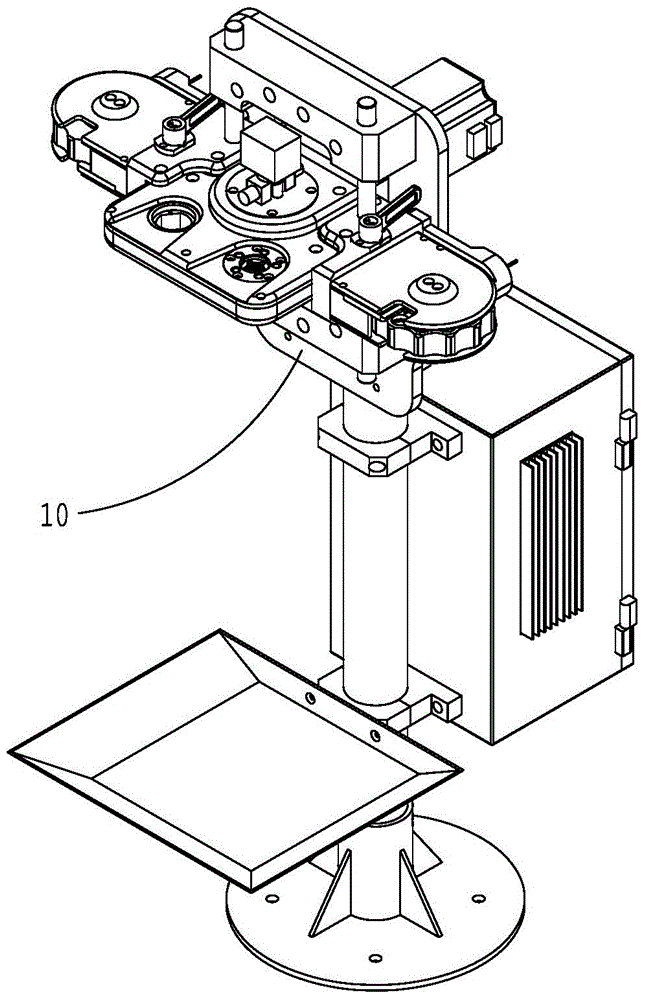

[0029] This embodiment introduces in detail a mold repairing and replacing equipment for electrode caps of welding machines, which includes a support member, a storage cap installation device, an electrode cap removal device and an electrode cap mold repairing device, and the above-mentioned devices are automatically controlled by an electric control box.

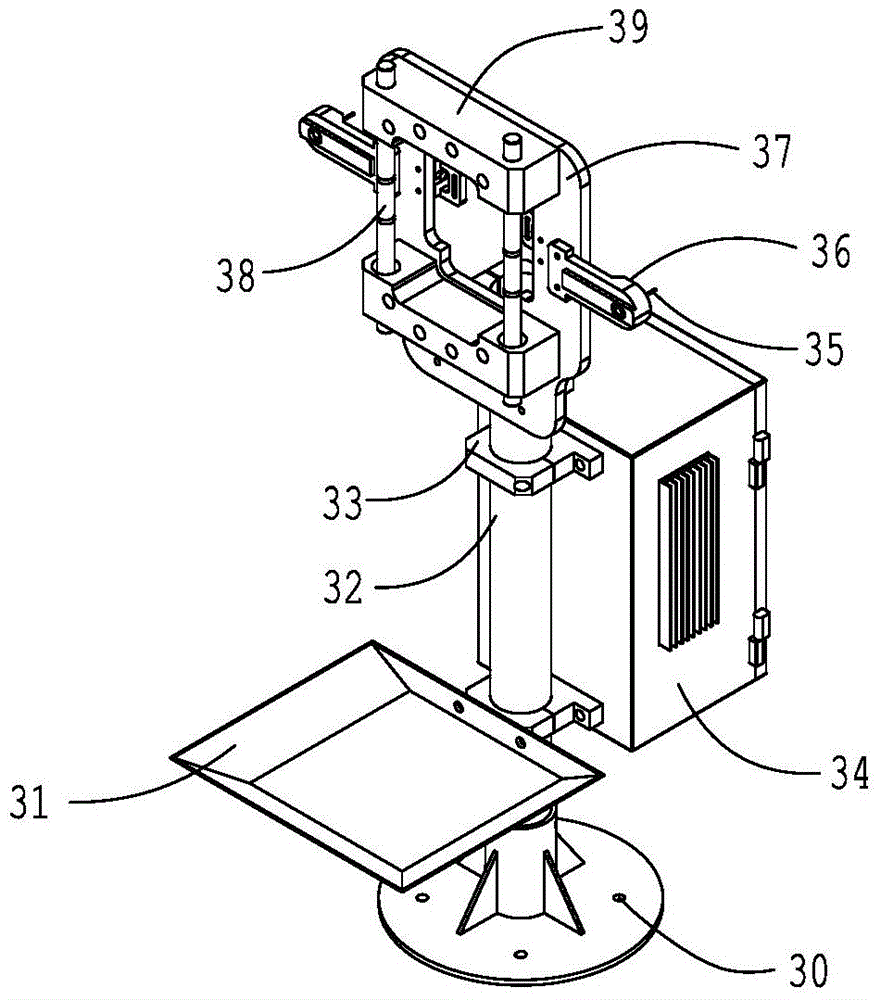

[0030] Such as image 3 , Figure 4 As shown, the structure of the supporting part includes a chassis 30, a chassis rod 32 and a mounting plate 37, the chassis is fixed on the ground by expansion screws, and its electrical control box 34 and copper scrap collection tray 31 are installed on the chassis by connecting buckles 33. On the bar 32, the mounting plate 37 is installed on the underframe bar 32, and the support block 36 is installed on the mounting plate 37, and a sensor 35 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com