Coping and replacing device of electrode cap

A technology for replacing equipment and electrode caps, applied in resistance welding equipment, grinding/polishing equipment, electrode maintenance, etc., can solve the problems of high raw material cost and manufacturing cost, complex structure of the jaw mechanism, etc., and achieve low cost and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

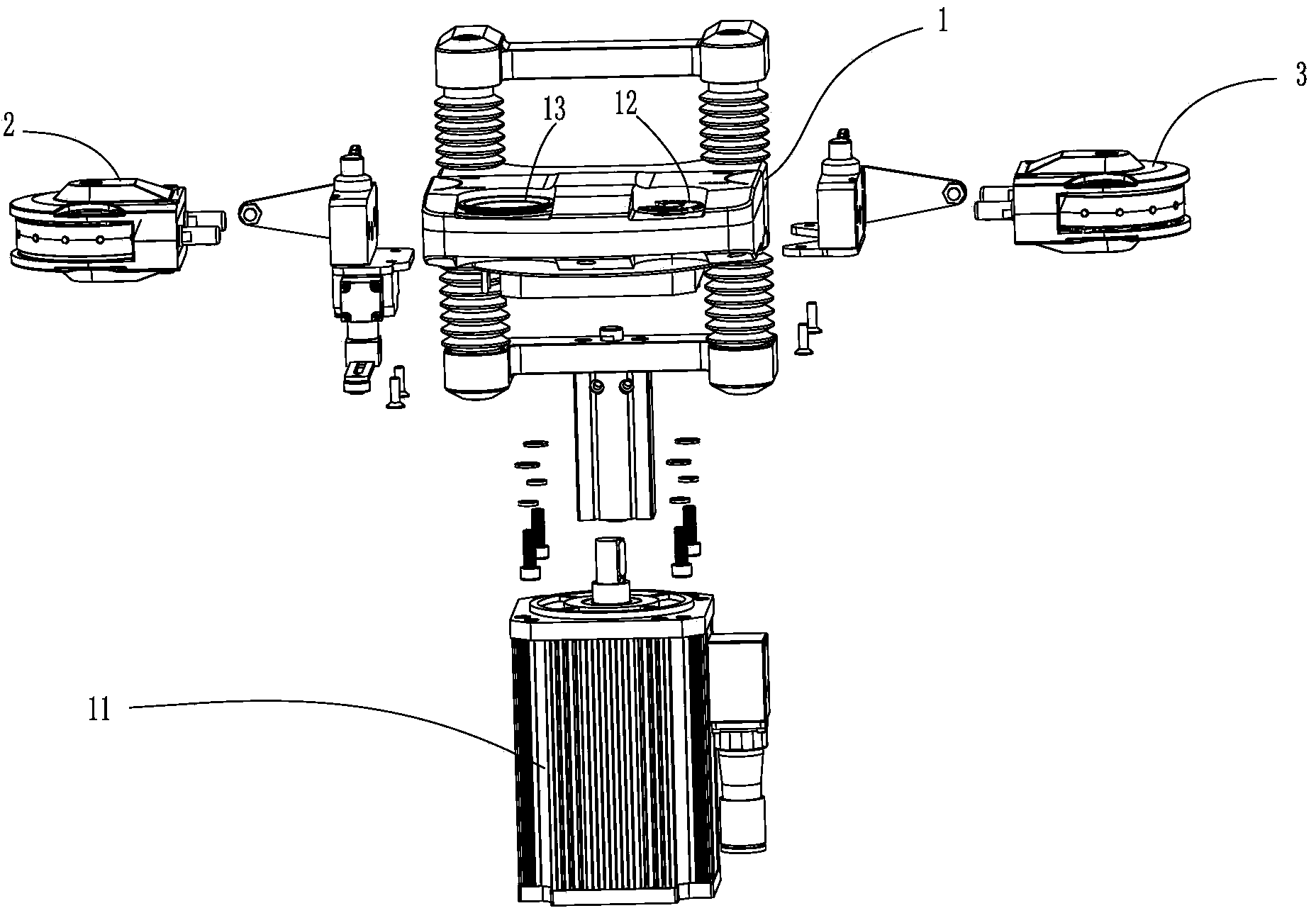

[0048] Such as figure 1 As shown, the electrode cap grinding and replacement equipment in this embodiment includes a machine head 1, two electrode cap supply devices (left supply 2 and right supply 3), and a travel switch.

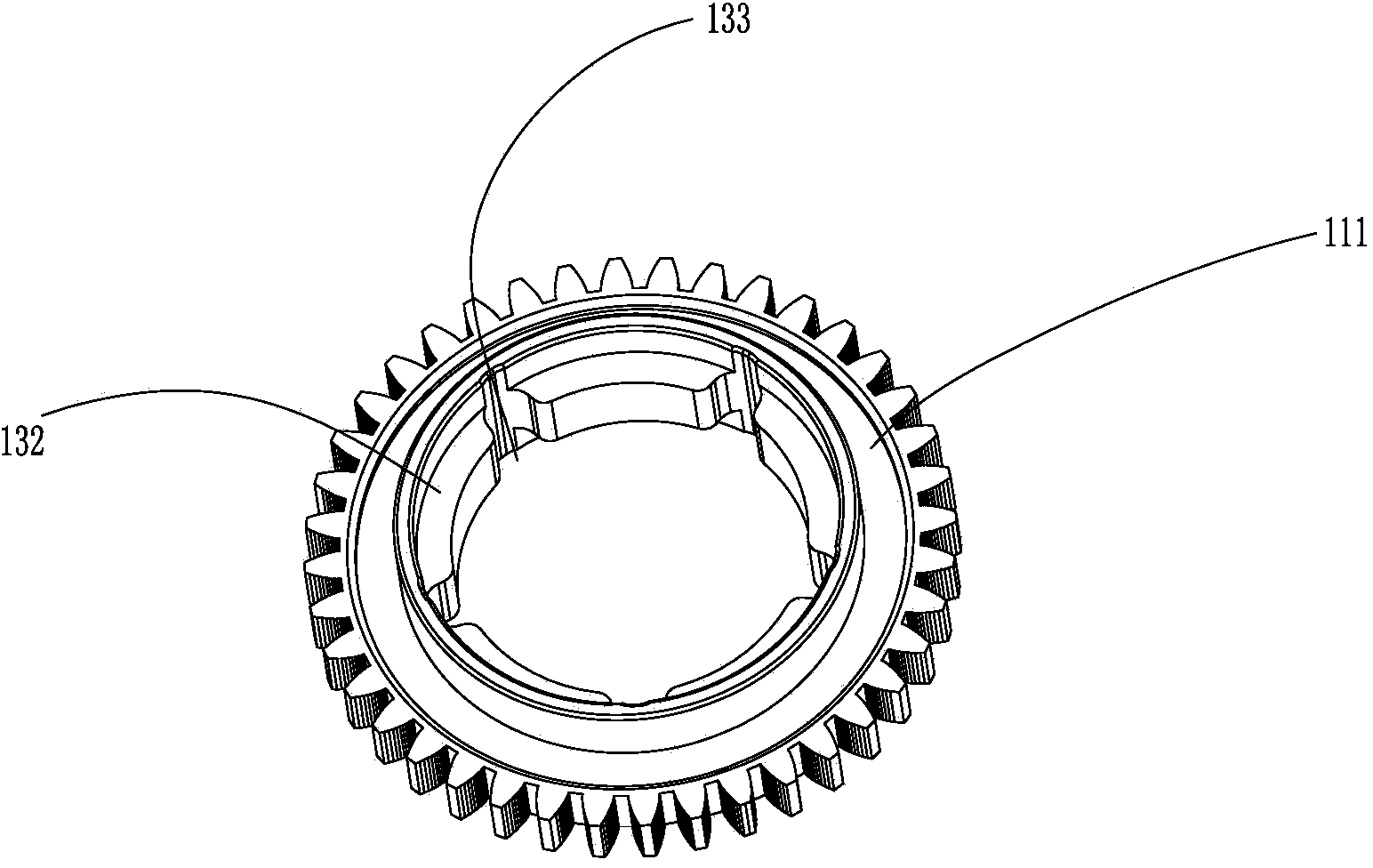

[0049] Wherein, the machine head includes a motor drive device 11 , a grinding device 12 and a dismounting device 13 . The motor driving device includes a motor and a gear transmission. The gear transmission includes an input gear driven by the motor and an output gear driven by the input gear. The output gear includes a grinding gear and a dismantling gear 111 . The grinding device includes a grinding knife edge driven to rotate by the grinding gear. The dismantling device includes a dismantling hole 131 for accommodating the electrode cap and a clamping mechanism 4 for clamping the motor cap; the dismantling hole is located at the center of the dismantling gear.

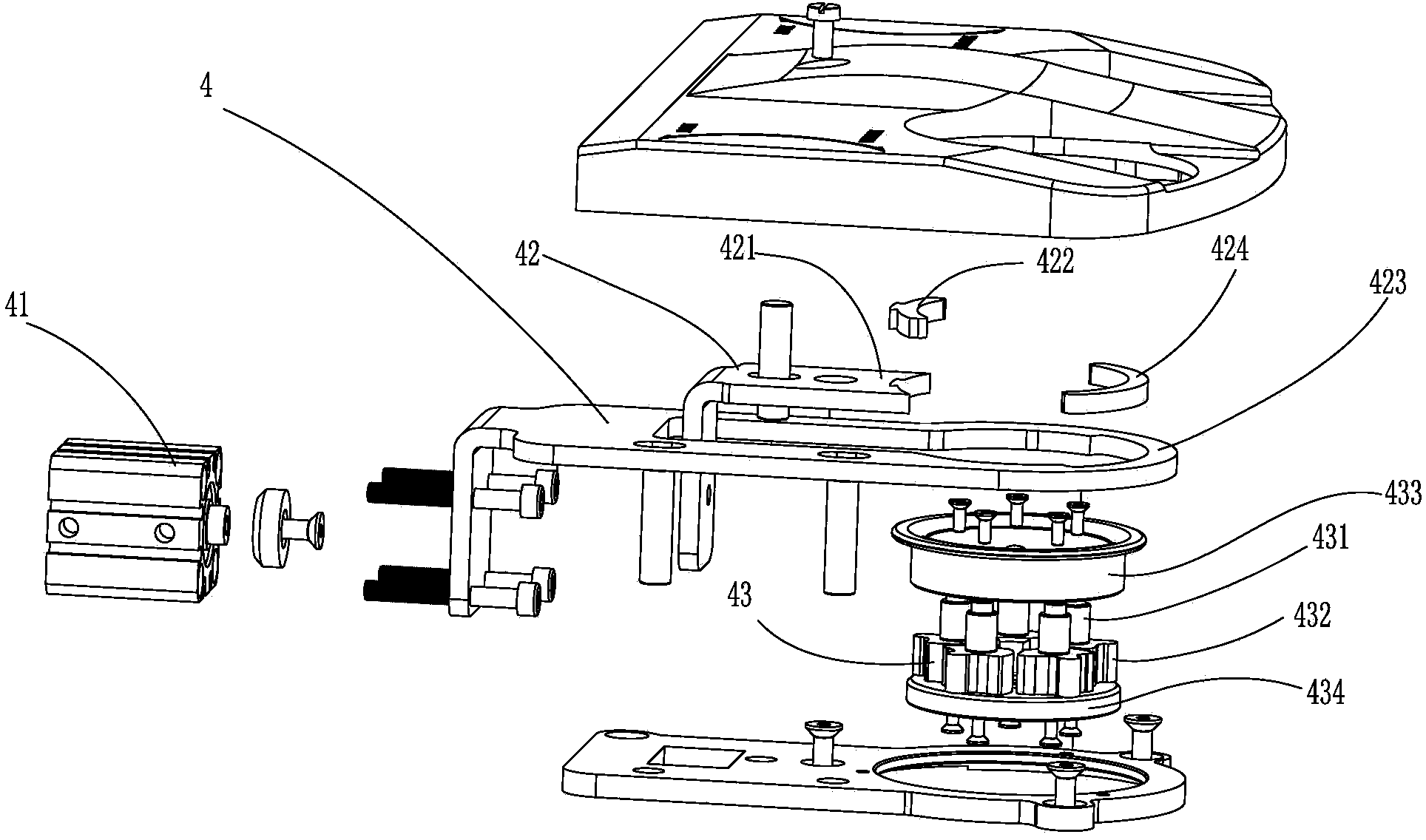

[0050] Such as figure 2 As shown, the clamping mechanism 4 includes a linear drive devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com