Sol-gel preparation method of ceramic bonding agent

A ceramic bond, sol-gel technology, used in manufacturing tools, metal processing equipment, abrasives, etc., can solve the problems of poor organizational uniformity, loose bonding of abrasives, phase-separation cracking, etc., to improve high-temperature fluidity and eliminate concentration. Difference, the effect of preventing particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

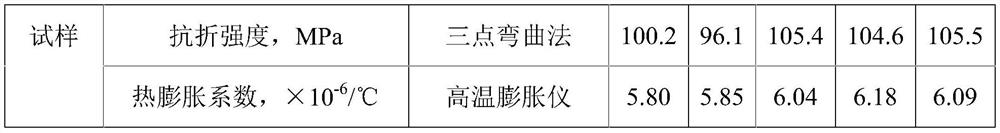

Examples

Embodiment 1

[0024] The vitrified bond of embodiment 1 is made up of the component of following mass percent:

[0025] ZnO 5%, ZrO 2 2%, Na 2 O 4%, Li 2 O 3%, Al 2 o 3 11%, B 2 o 3 19%, TiO 2 6%, SiO 2 50%.

[0026] Calculate the amount of raw materials zinc acetate, zirconium acetate, sodium nitrate, lithium nitrate, aluminum nitrate, boric acid, tetrabutyl titanate and acidic silica sol according to the mass ratio of the above oxides, and prepare the ingredients for later use.

[0027] The sol-gel preparation method of above-mentioned ceramic bond comprises the following steps:

[0028] 1) dissolving zinc acetate and zirconium acetate in an aqueous acetic acid solution with a mass concentration of 20% to form a mixed solution A; in the resulting mixed solution A, control the total concentration of zinc acetate and zirconium acetate to be 1.0mol / L;

[0029] Boric acid is dissolved in water to make boric acid solution, and sodium nitrate, lithium nitrate, and aluminum nitrate...

Embodiment 2

[0034] The vitrified bond of embodiment 2 is made up of the component of following mass percent:

[0035] ZnO 4%, ZrO 2 3%, Na 2O 4%, Li 2 O 3%, Al 2 o 3 10%, B 2 o 3 18%, TiO 2 6%, SiO 2 52%.

[0036] Calculate the amount of raw materials zinc acetate, zirconium acetate, sodium nitrate, lithium nitrate, aluminum nitrate, boric acid, tetrabutyl titanate and acidic silica sol according to the mass ratio of the above oxides, and prepare the ingredients for later use.

[0037] The sol-gel preparation method of above-mentioned ceramic bond comprises the following steps:

[0038] 1) dissolving zinc acetate and zirconium acetate in an aqueous acetic acid solution with a mass concentration of 20% to make a mixed solution A; in the mixed solution A, the total concentration of zinc acetate and zirconium acetate is 1.0mol / L;

[0039] Boric acid is dissolved in water to make boric acid solution, and sodium nitrate, lithium nitrate, and aluminum nitrate are dissolved in bori...

Embodiment 3

[0044] The vitrified bond of embodiment 3 is made up of the component of following mass percent:

[0045] ZnO 5%, ZrO 2 2%, Na 2 O 3%, Li 2 O 4%, Al 2 o 3 9%, B 2 o 3 16%, TiO 2 6%, SiO 2 55%.

[0046] Calculate the amount of raw materials zinc acetate, zirconium acetate, sodium nitrate, lithium nitrate, aluminum nitrate, boric acid, tetrabutyl titanate and acidic silica sol according to the mass ratio of the above oxides, and prepare the ingredients for later use.

[0047] The sol-gel preparation method of above-mentioned ceramic bond comprises the following steps:

[0048] 1) dissolving zinc acetate and zirconium acetate in an aqueous acetic acid solution with a mass concentration of 20% to make a mixed solution A; in the mixed solution A, the total concentration of zinc acetate and zirconium acetate is 1.0mol / L;

[0049] Boric acid is dissolved in water to make boric acid solution, and sodium nitrate, lithium nitrate, and aluminum nitrate are dissolved in bori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com