Three-stage countercurrent absorption process and apparatus for acidic gases

A three-stage countercurrent, acid gas technology, applied in inorganic chemistry, sulfur compounds, dispersed particle separation, etc., can solve the problems of difficult operation of the device, long process, easy deterioration of sodium sulfide, etc., to prevent crystallization and reduce the concentration of Na2S. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

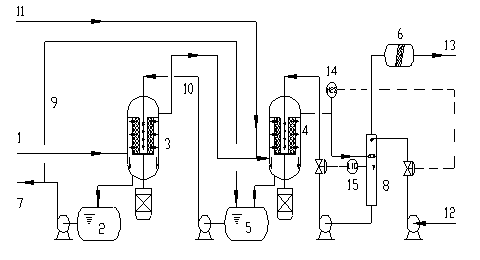

[0055] use as figure 1 The process device shown uses acid gas and NaOH solution with a mass concentration of 35% as raw materials for reaction. CO in acid gas 2 The volume fraction is 7%, H 2 The volume fraction of S is 92%, and the volume fraction of hydrocarbons is 1%.

[0056] In the embodiment of the present invention, the primary reactor and the secondary reactor adopt rotary bed reactors, and the reaction temperature in the primary rotary bed reactor and the secondary rotary bed reactor is 85°C. The temperature of the primary intermediate tank and the secondary intermediate tank is 90°C. The rotational speed of the primary rotary bed reactor and the secondary rotary bed reactor is 1500 rpm. The residence time of the reaction materials in the reactor was 10 seconds.

[0057] In the process of the present invention, in step (1), the volume flow ratio of the reaction product liquid circulated back to the secondary intermediate tank and the total reaction product liquid o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com