Staggered sieve plate installation structure of circular flowing type sieve plate tower

A technology of installation structure and sieve plate tower, which is applied in the direction of distillation separation, chemical instruments and methods, separation methods, etc., and can solve the problems of high purity requirements of rectification, high cost, and many material ports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

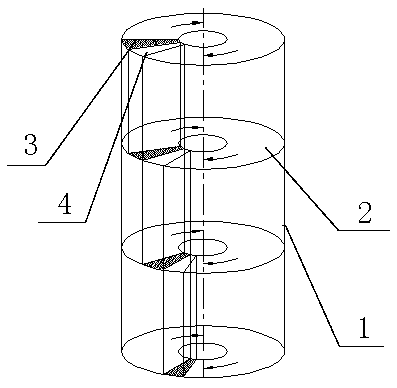

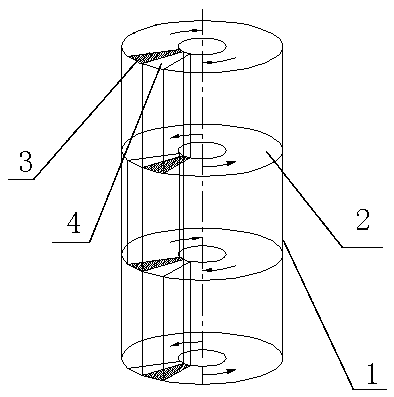

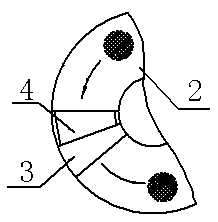

[0013] Embodiment: Based on the design of the circulation type sieve tray tower, the design of the k-th sieve plate and the k+1-th sieve plate reverse flow direction, and the design positions of the liquid receiving tank and the downcomer are changed alternately.

[0014] During the installation process, ensure that the liquid receiving tank of the kth floor tray is aligned with the downcomer position of the k+1th layer, and ensure that the liquid receiving tank in the splitter tower and the downcomer in the vertical direction are basically consistent in the top view installation angle position, Reduce assembly deviation.

[0015] The staggered circulation sieve plate splitter tower of the present invention makes the internal circulation liquid flow alternately in forward and reverse directions, and can well solve the restriction caused by the throttling error. Through the product test verification, the rectification efficiency of the new staggered circulation tower is higher ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com