Dispersing apparatus

A dispersing device and dispersing technology, applied in the direction of grain processing, etc., can solve the problems of complex structure and complex manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0058] In order to confirm the dispersing effect of the dispersing device with the above-mentioned structure, a comparative test was carried out. (Test example)

[0059] Samples 1 to 7 and comparative samples 1 to 7

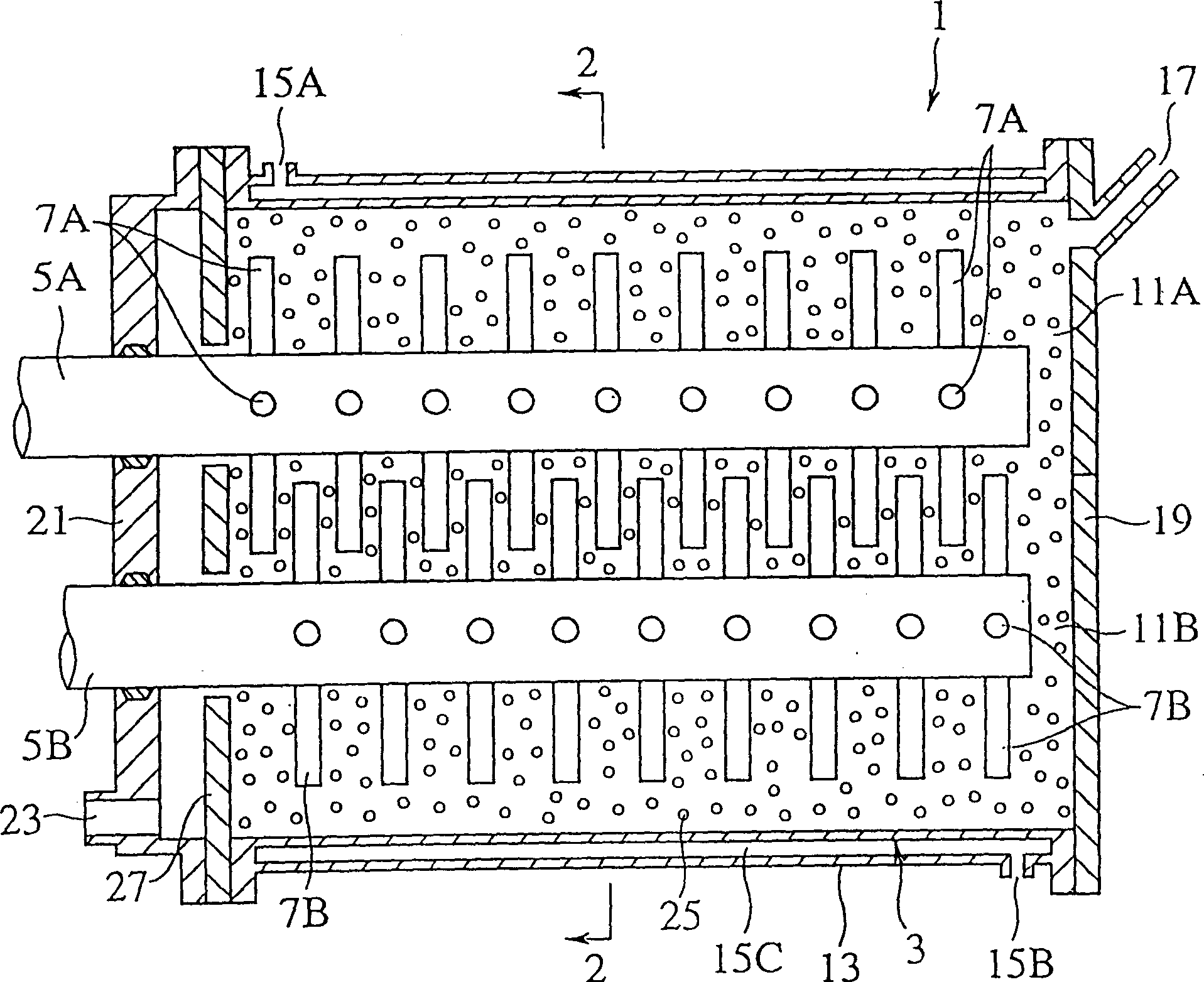

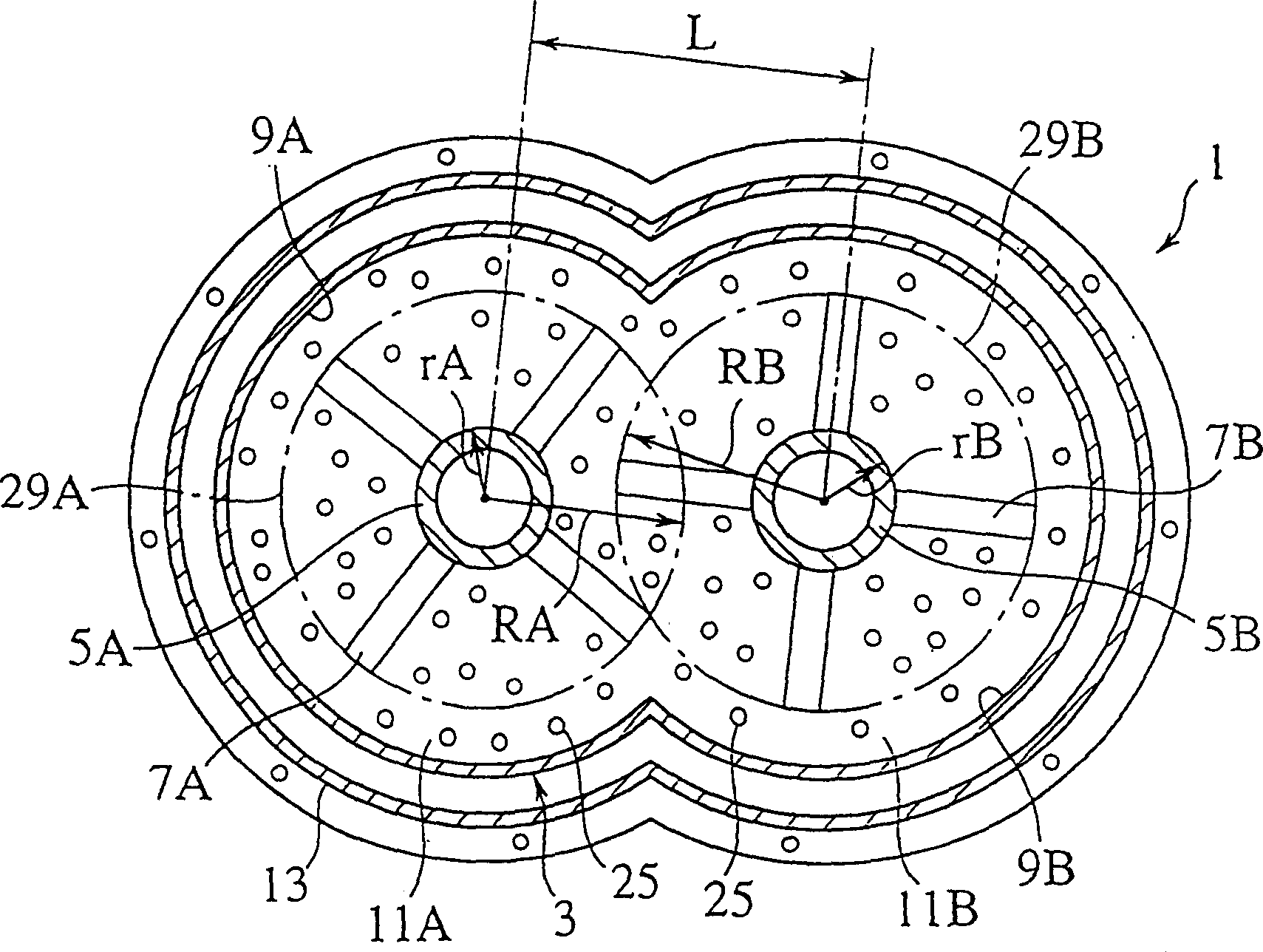

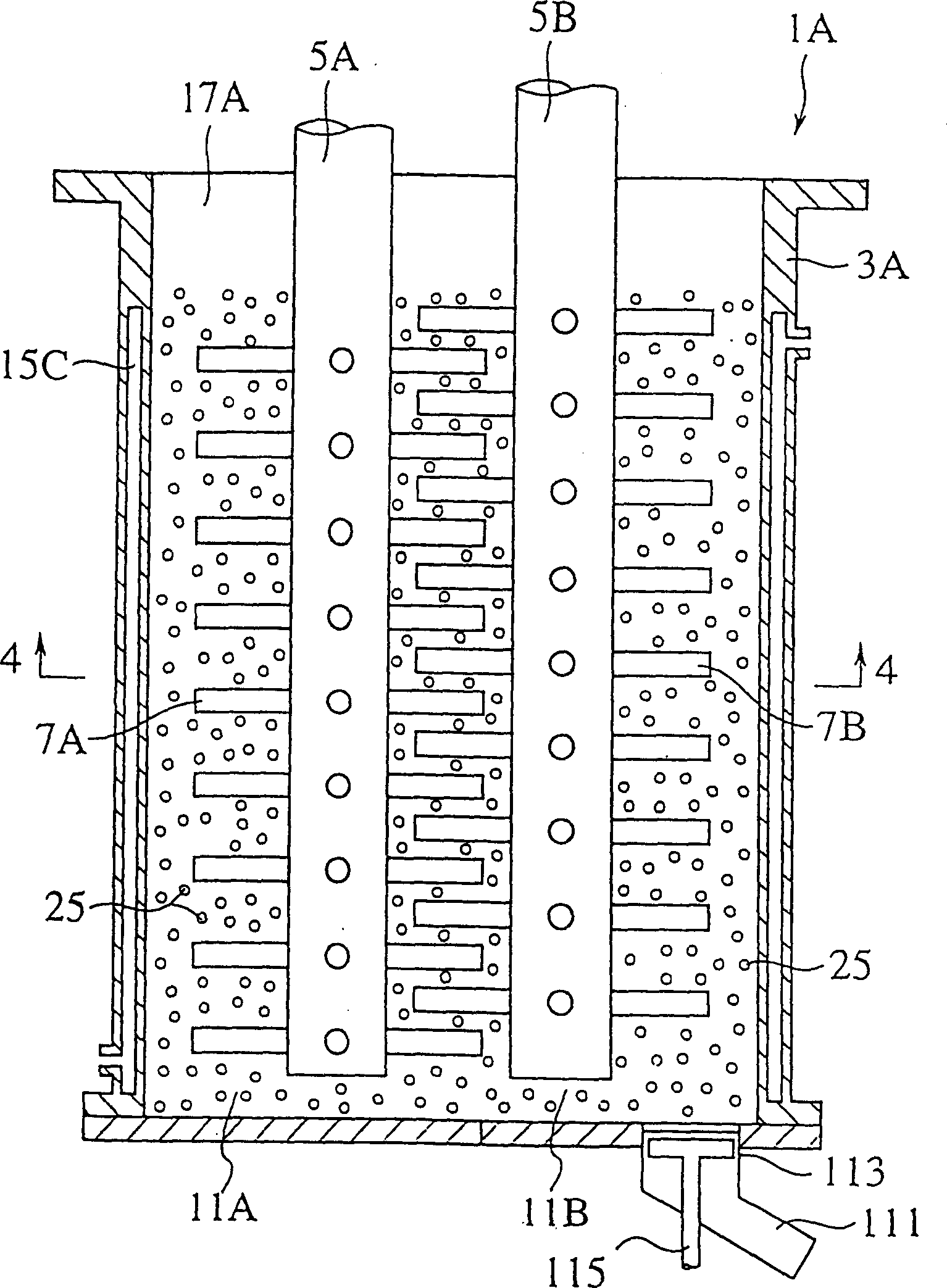

[0060] Pigment (12 parts by weight), alkyd resin (38 parts by weight) and xylene (40 parts by weight) are mixed in the above ratio, and then used according to the present invention. figure 1 versus figure 2 The dispersion device of the structure shown performs dispersion. As a result, a dispersed pigment paste was prepared. Melamine resin (12 parts by weight) is mixed with the dispersed pigment paste (88 parts by weight) to prepare an alkyd / melamine coating material. As the coating material of the comparative sample, the raw material having the same composition as the above sample, using commonly used materials such as Figure 7 The dispersing device of the uniaxial sand mill structure shown is obtained by dispersing at the same time. The measured particle size dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com