Method of producing round billets and its equipment

A technology for production equipment and round blanks, applied in metal processing equipment, workpiece surface treatment equipment, metal rolling, etc., can solve problems such as limited influence and inability to position forging equipment, so as to increase material density, ensure roundness and dimensional stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

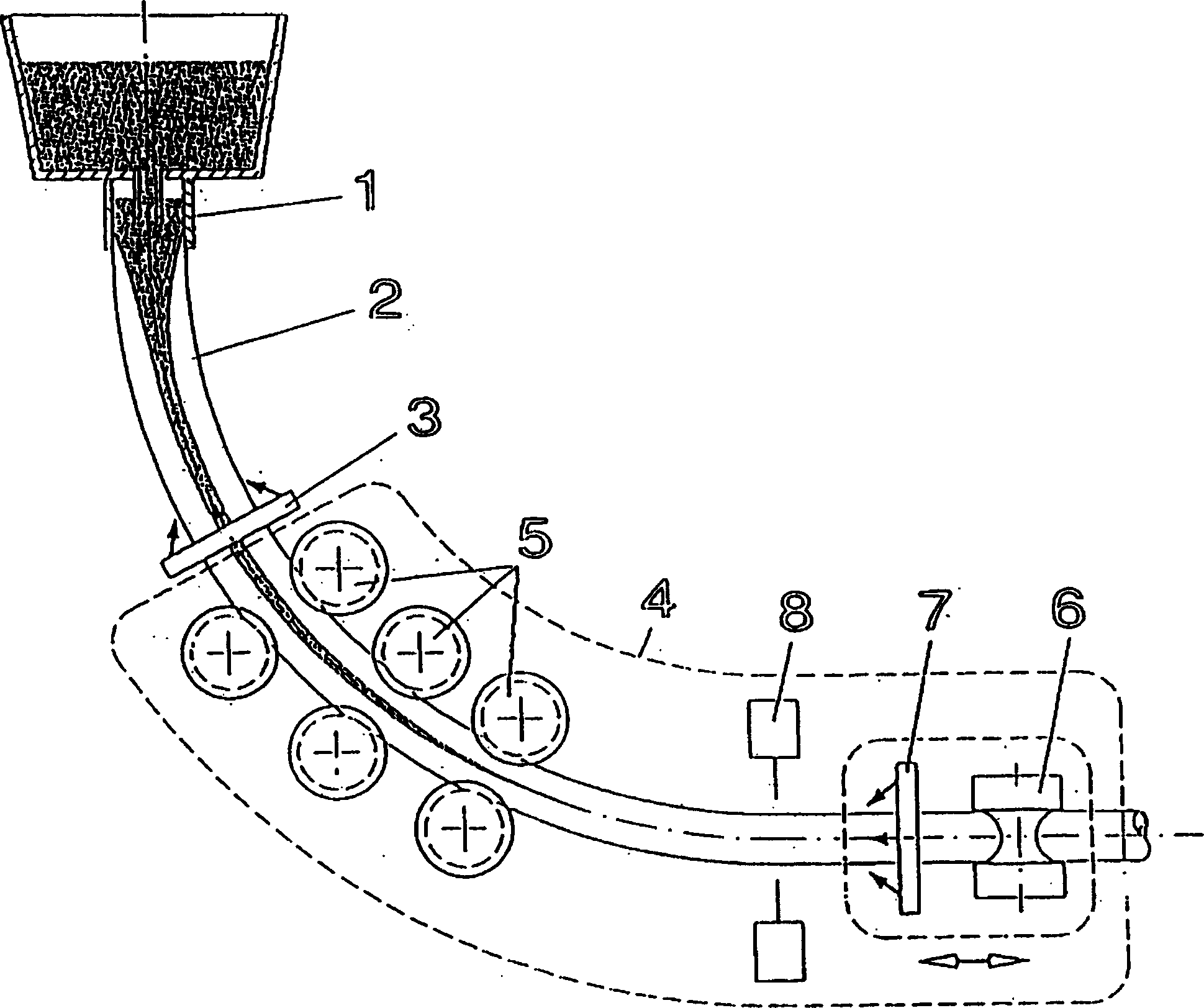

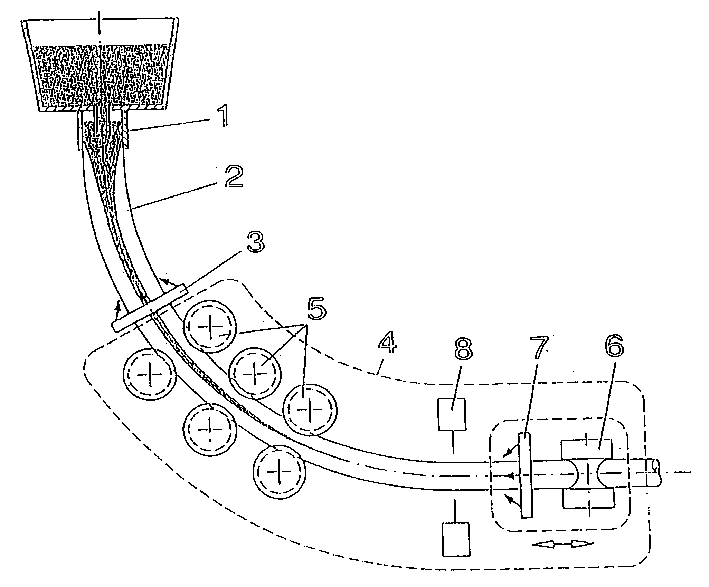

[0024] 1 represents a vertical round billet continuous casting machine with a horizontal outlet, in its crystallizer, a round billet with a thickness of 90-300 mm is poured and drawn down. The round blanks 2 are turned from the vertical into the horizontal in the arc-shaped frame section of the plant and are processed here in the manner according to the invention. For this purpose, the round billet, which still has a liquid core, is firstly descaled in the primary descaling device 3 and cooled at the same time in order to provide surface conditions for the subsequent rolling deformation of the round billet. The deformation takes place in a multi-stand rolling installation 4 which consists of three successive horizontal stands 5 which each have a circular sizing device formed by two transition radii. The last horizontal stand can be adjusted under the rolling load and is equipped with a roll gap adjustment mechanism corresponding to the gauge 8 for the width and thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com