Apparatus and method for reaction

A reaction equipment and reaction technology, applied in chemical instruments and methods, chemical methods for reacting liquids and liquids, chemical/physical/physicochemical fixed reactors, etc., can solve the problem of decreased sphericity of precursors, decreased productivity, Uneven stirring speed and other problems, to achieve the effect of suppressing the concentration difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

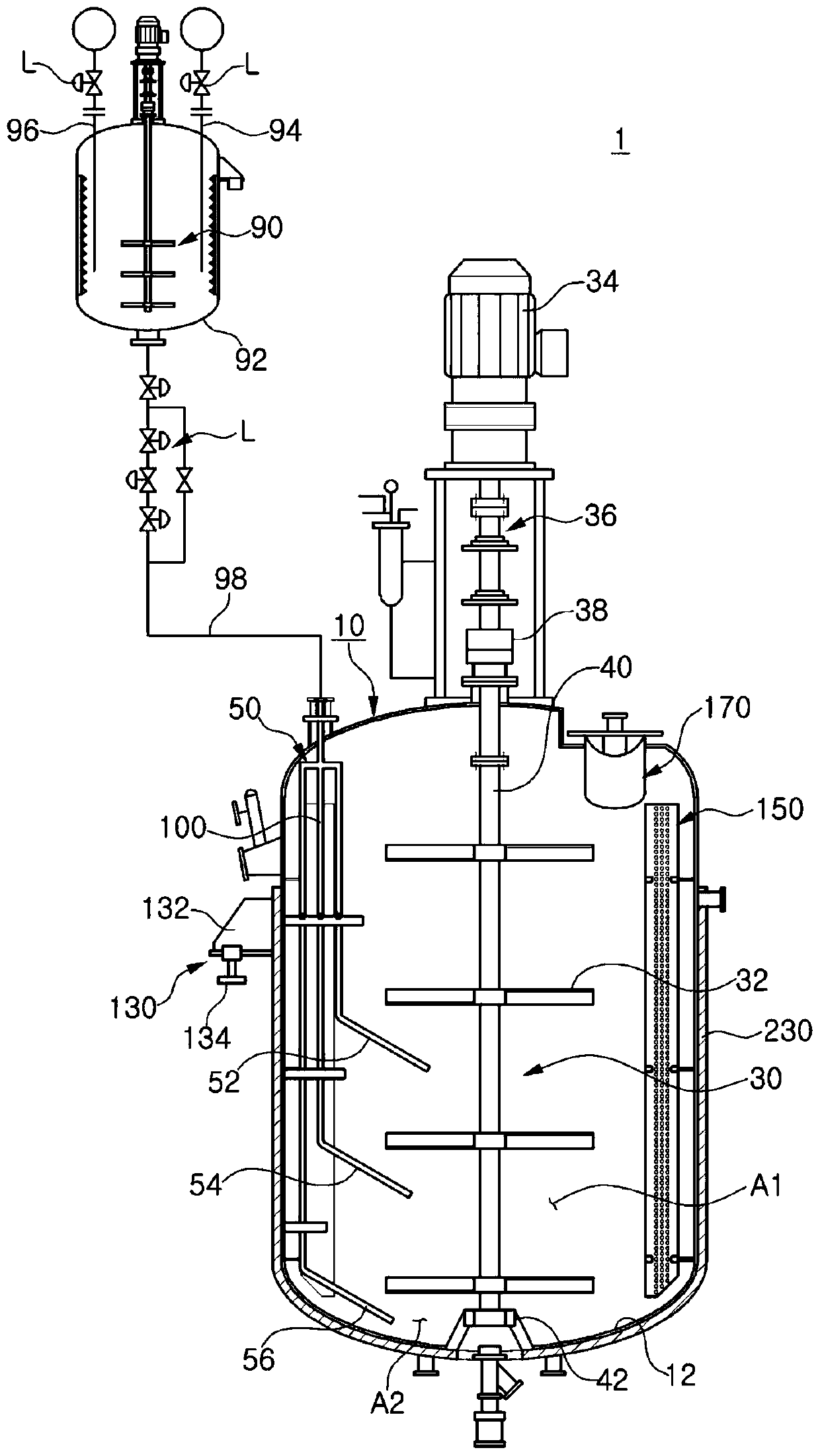

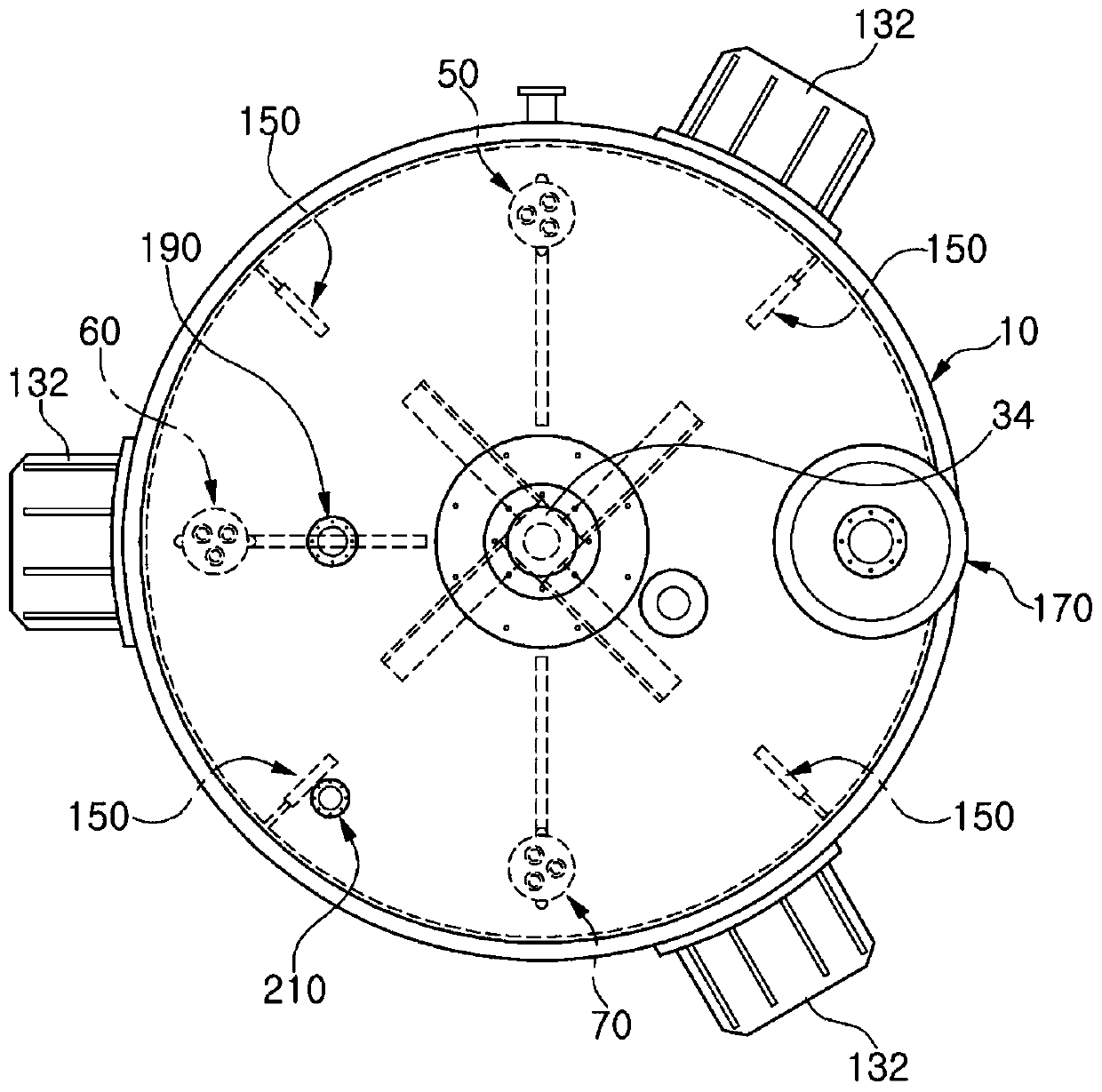

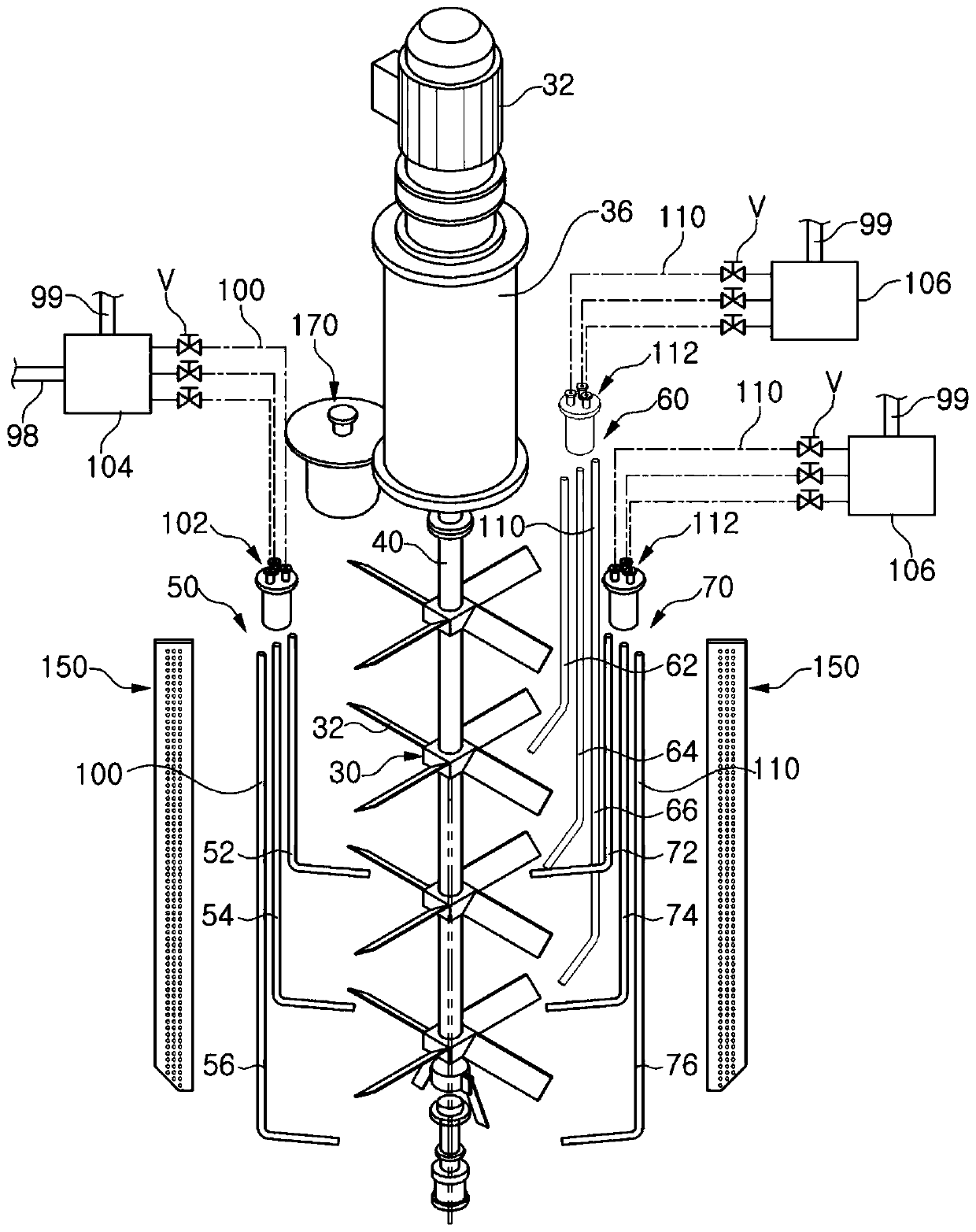

[0042]Hereinafter, the present invention will be described in detail by way of exemplary drawings. It should be noted that for identical components, the same reference numerals are used as far as possible even in different drawings. In addition, when describing the present invention, if it is considered that the detailed description of related known structures or functions may make the gist of the present invention unclear, the detailed description will be omitted.

[0043] First, the reaction device 1 of the present invention described in this embodiment may be a co-precipitation reaction device for preparing positive electrode active materials for lithium secondary batteries based on a continuous stirred tank reactor (CSTR).

[0044] Of course, the reaction device of the present invention is not limited to be used in the environment of preparing positive electrode active materials. For example, it can be applied to the reaction (preparation) of other materials in which the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com