Dry powder lost foam casting coating

A lost foam casting and coating technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of insufficient coating strength, easy delamination, poor suspension, etc. The effect of long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

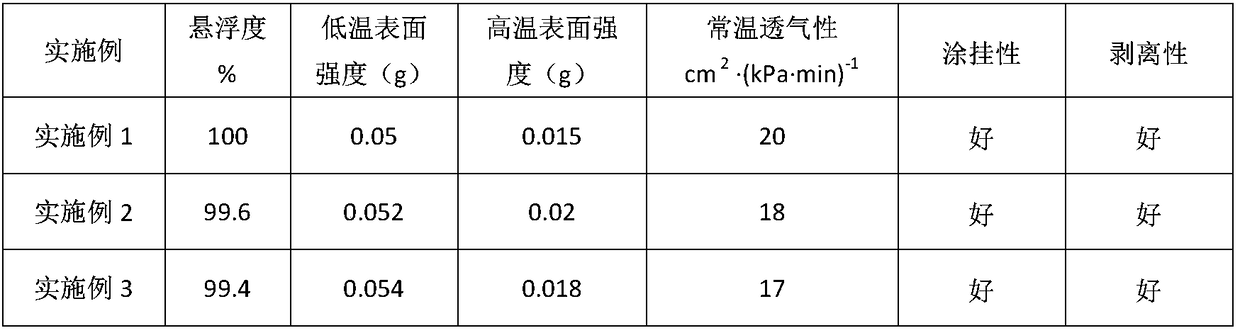

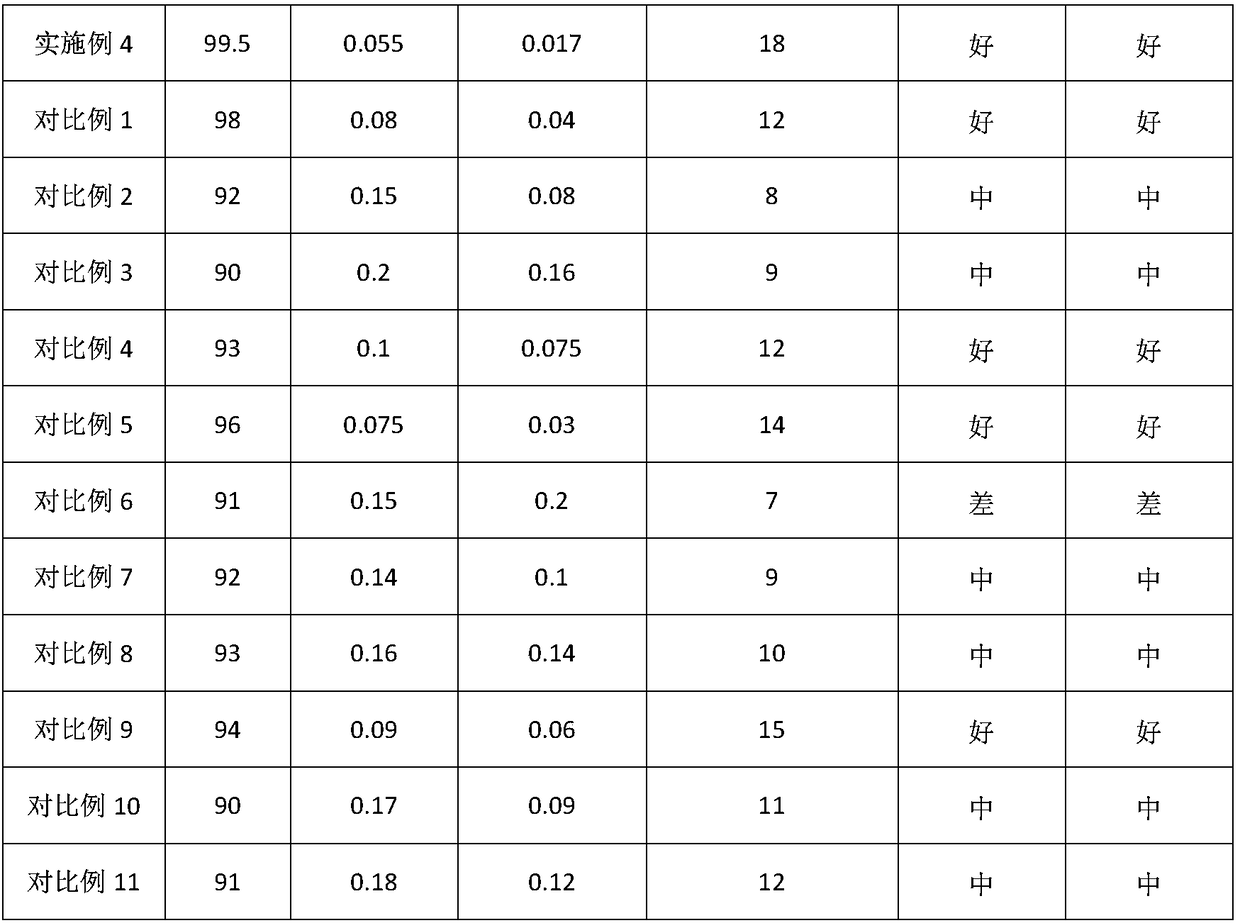

Examples

Embodiment 1

[0030] Prepare 73 parts of high-alumina powder with a particle size of 280-320 mesh, 17 parts of zircon powder with a particle size of 280-300 mesh, 8 parts of sepiolite with a particle size of 280-320 mesh, and a sodium base with a particle size of 280-320 mesh. 2 parts of bentonite, 1.2 parts of sodium methylene dinaphthalene sulfonate, 2 parts of sodium pyrophosphate, 2.4 parts of yellow dextrin, 1 part of potato flour, and 0.02 parts of defoamer. First add high alumina powder, zircon powder, sepiolite, and sodium bentonite into the mill for the first grinding to obtain mixture A, then mix mixture A, sodium methylene dinaphthalene sulfonate, and sodium pyrophosphate , yellow dextrin, and potato flour are added into the mill and milled for the second time to obtain mixture B, which is the dry powder lost foam casting coating; the pressure of the first milling is 40MPa, and the milling speed is 800rpm. The grinding time is 30 minutes; the pressure of the second grinding is 20...

Embodiment 2

[0032] Prepare 74 parts of high-alumina powder with a particle size of 240-320 mesh, 18 parts of zircon powder with a particle size of 240-320 mesh, and 9 parts of sepiolite with a particle size of 240-320 mesh. 3 parts of 240-320 mesh sodium bentonite, 1.4 parts of sodium methylene dinaphthalene sulfonate, 3 parts of sodium pyrophosphate, 3 parts of yellow dextrin, 1.2 parts of potato flour, and 0.03 parts of defoamer. First add high alumina powder, zircon powder, sepiolite, and sodium bentonite into the mill for the first grinding to obtain mixture A, then mix mixture A, sodium methylene dinaphthalene sulfonate, and sodium pyrophosphate , yellow dextrin, and potato flour are added to the mill for the second milling to obtain mixture B, which is the dry powder lost foam casting coating;

[0033]The first milling pressure is 38MPa, the milling speed is 700rpm, and the milling time is 28min; the second milling pressure is 19MPa, the milling speed is 480rpm, and the milling time...

Embodiment 3

[0035] Prepare 70 parts of high-alumina powder with a particle size of 200-320 mesh, 15 parts of zircon powder with a particle size of 200-320 mesh, and 7 parts of sepiolite with a particle size of 200-320 mesh. 1 part of 200-320 mesh sodium bentonite, 0.65 parts of sodium methylene dinaphthalene sulfonate, 1.2 parts of sodium pyrophosphate, 1.5 parts of yellow dextrin, 1 part of potato flour, and 0.01 part of defoamer; Zircon powder, sepiolite, and sodium bentonite are added to the mill for the first grinding to obtain mixture A, and then mixture A, sodium methylene dinaphthalene sulfonate, sodium pyrophosphate, yellow dextrin, potato The powder is added to the mill for the second milling to obtain the mixture B, which is the dry powder lost foam casting coating; the pressure of the first milling is 30MPa, the milling speed is 600rpm, and the milling time is 20min; The pressure of the second milling is 10 MPa, the milling speed is 400 rpm, and the milling time is 20 minutes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com