Additive raw material composite and additive for superhard material product, preparation method of additive, combined binder and superhard material product

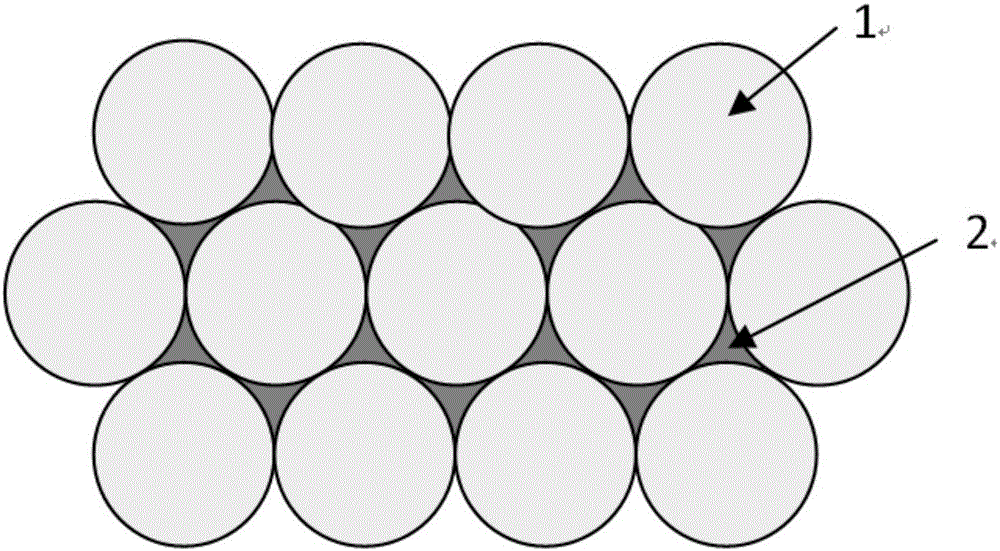

A technology of composite binder and raw material composition, which is applied in the direction of metal processing equipment, abrasives, manufacturing tools, etc., can solve the problems of limited improvement of grinding wheel grinding efficiency and service life, and is not easy to disperse evenly, so as to improve grinding efficiency and service life, low refractoriness and fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

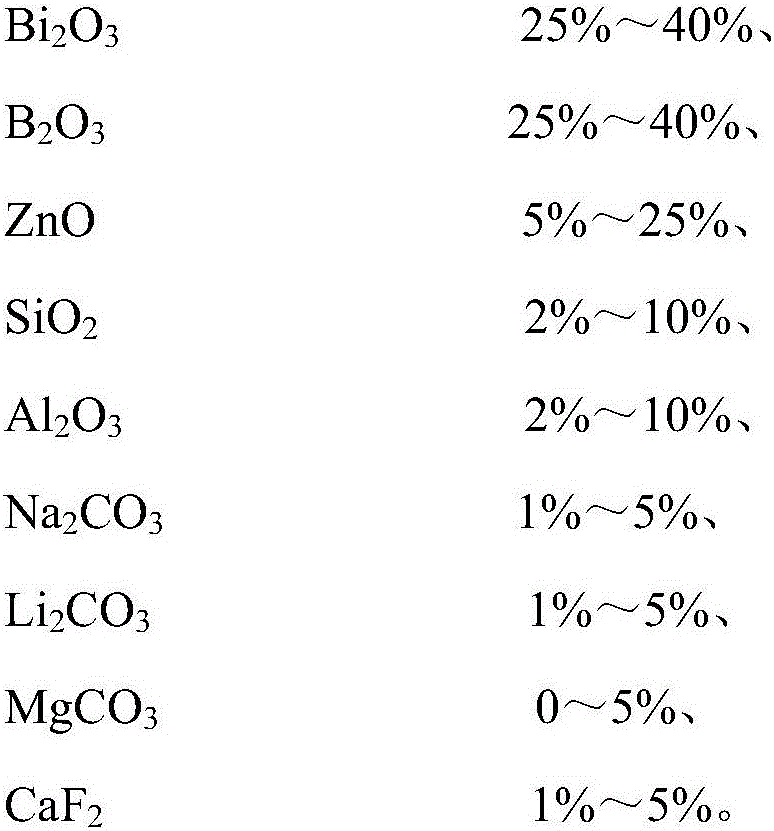

[0036] The additive raw material composition for superhard material products of this embodiment consists of the following components in mass percentage:

[0037]

[0038] The additive for superhard material products of this embodiment is made from the above-mentioned raw material composition, and the preparation method includes the following steps:

[0039] 1) Take Bi of formula quantity 2 o 3 , B 2 o3 , ZnO, SiO 2 、Al 2 o 3 、Na 2 CO 3 , Li 2 CO 3 , MgCO 3 After mixing evenly, put it into a quartz crucible, place it in a high-temperature resistance furnace, heat it at 10°C / min to 1250°C and keep it warm for 2 hours to obtain a mixture;

[0040] 2) Cool the mixture obtained in step 1) to 850°C at a rate of 5°C / min, and add the formula amount of CaF 2 And stir and mix, keep warm for 2h to get sintered product;

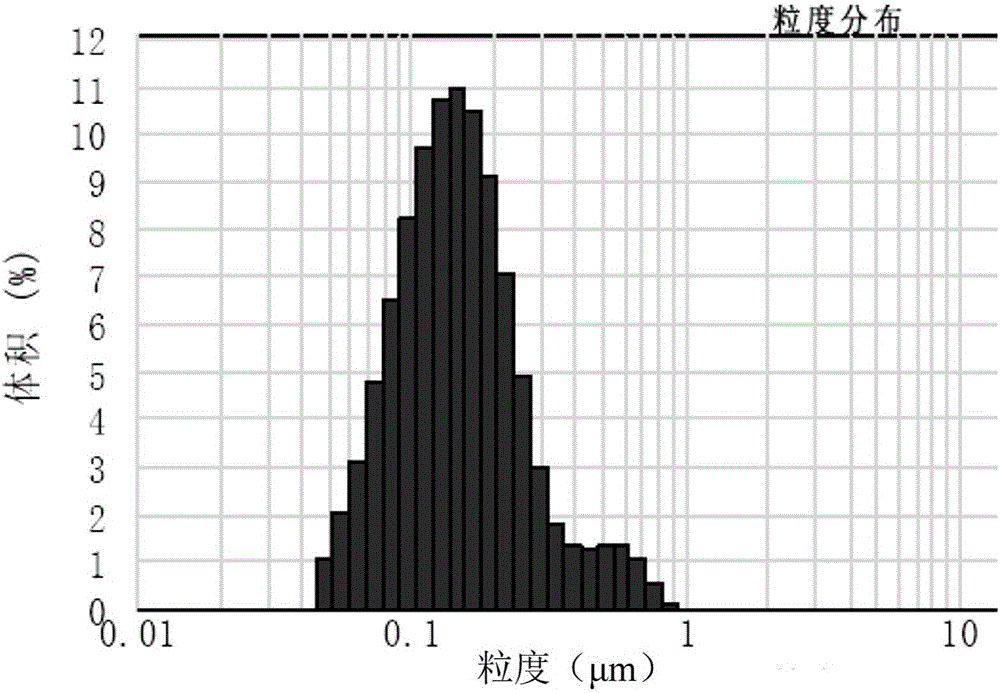

[0041] 3) Pour the sintered product obtained in step 2) into cold water for quenching to obtain a block material; according to the volume ratio of the mat...

Embodiment 2

[0049] The additive raw material composition for superhard material products of this embodiment consists of the following components in mass percentage:

[0050]

[0051]

[0052] The additive for superhard material products of this embodiment is made from the above-mentioned raw material composition, and the preparation method includes the following steps:

[0053] 1) Take Bi of formula quantity 2 o 3 , B 2 o 3 , ZnO, SiO 2 、Al 2 o 3 、Na 2 CO 3 , Li 2 CO 3 After mixing evenly, put it into a quartz crucible, place it in a high-temperature resistance furnace, heat it at 10°C / min to 1300°C and keep it warm for 1 hour to obtain a mixture;

[0054] 2) Cool the mixture obtained in step 1) to 850°C at a rate of 5°C / min, and add the formula amount of CaF 2 And stir and mix, keep warm for 2h to get sintered product;

[0055] 3) Pour the sintered product obtained in step 2) into cold water for quenching to obtain a block material; according to the volume ratio of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com