Vitrified bond, preparation method and manufacturing method of vitrified bonded abrasive tool

A vitrified bond and ball milling technology, applied in the manufacture of tools, abrasives, grinding devices, etc., can solve the problems of reducing the strength of vitrified bond, affecting the refractoriness of vitrified bond, low thermal expansion coefficient, strength stability, etc., and achieve temperature distribution Uniformity, solve the effect of high preparation cost and unstable performance of vitrified bond, uniform overall reaction and reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Vitrified bond and its preparation method embodiment

[0025] The preparation method step of vitrified bond of the present invention is:

[0026] Material preparation step: prepare raw materials according to the components and contents in Table 1, wherein the particle size of ultrafine silicon dioxide is not greater than 5 microns;

[0027] Drying step: Put the prepared raw materials into an oven and keep them warm for 3 hours at 300 degrees Celsius;

[0028] Ball milling step: Put the heat-preserved raw materials into a star ball mill or a high-energy ball mill, mill at 300 rpm for 5-6 hours, and cool to room temperature;

[0029] Screening step: pass the cooled raw material through a 180-mesh sieve;

[0030] Repeat the above ball milling steps and sieving steps until all raw materials pass through a 180-mesh sieve.

[0031] Table 1 Components and content

[0032]

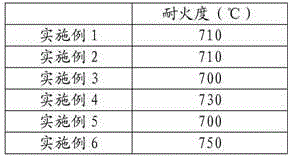

[0033] Refractory cones were used to test the refractoriness of the vitrified bonds prepared in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com