Fire-proof coating used for die casting

A technology for refractory coatings and molds, applied in coatings, casting molding equipment, casting molds, etc., to achieve good wettability and adhesion, good coating and hanging properties, and easy drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

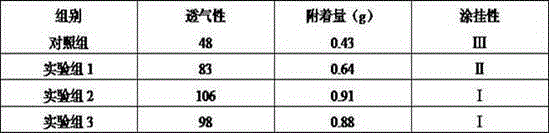

Examples

Embodiment 1

[0029] A refractory coating for mold casting, which is composed of the following raw materials: bauxite 4kg, quartz powder 3kg, corundum 1kg, diatomite 1kg, talcum powder 1kg, cryolite 0.1kg, CMC 0.8kg, polyethylene Alcohol 0.3kg, water glass 0.3kg, sodium phosphate 0.1kg.

[0030] The preparation method is that water is used as a carrier, and all raw materials are mixed evenly in proportion.

Embodiment 2

[0032] A refractory coating for mold casting, which is composed of the following raw materials: bauxite 6kg, quartz powder 1kg, corundum 0.5kg, diatomite 0.5kg, talcum powder 0.5kg, cryolite 0.3kg, CMC 0.3kg , polyvinyl alcohol 0.1kg, water glass 0.8kg, sodium phosphate 0.3kg.

[0033] The preparation method is that water is used as a carrier, and all raw materials are mixed evenly in proportion.

Embodiment 3

[0035] A refractory coating for mold casting is composed of the following raw materials: 4.5kg of bauxite, 2.5kg of quartz powder, 0.8kg of corundum, 0.6kg of diatomaceous earth, 0.8kg of talcum powder, 0.1kg of cryolite, CMC0 .4kg, polyvinyl alcohol 0.1kg, water glass 0.6kg, sodium phosphate 0.1kg, fatty alcohol polyoxyethylene ether 0.02kg.

[0036] The preparation method is that water is used as a carrier, and all raw materials are mixed evenly in proportion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com