Cast iron sand mold protecting coating coated to surface of 40-120-mesh sand and preparation method thereof

A technology of protective coating and cast iron sand, applied in coating, casting molding equipment, casting molds, etc., can solve the problems of reducing the thickness of ductile iron castings and the thickness of ductile iron castings, and reduce the thickness of bad spheroidization. , Improve flatness, good effect of coating and hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 also provides the preparation method of cast iron sand mold protective coating, and the steps are as follows:

[0057] (1) Mix the binder and the suspending agent in the solvent, and emulsify and stir at a high speed of 30°C for 30 minutes in the reaction kettle to obtain the bonding system;

[0058] (2) Disperse the refractory aggregate in the bonding system obtained in step (1), stir and disperse at a high speed for 60 minutes, and obtain a cast iron sand mold protective coating.

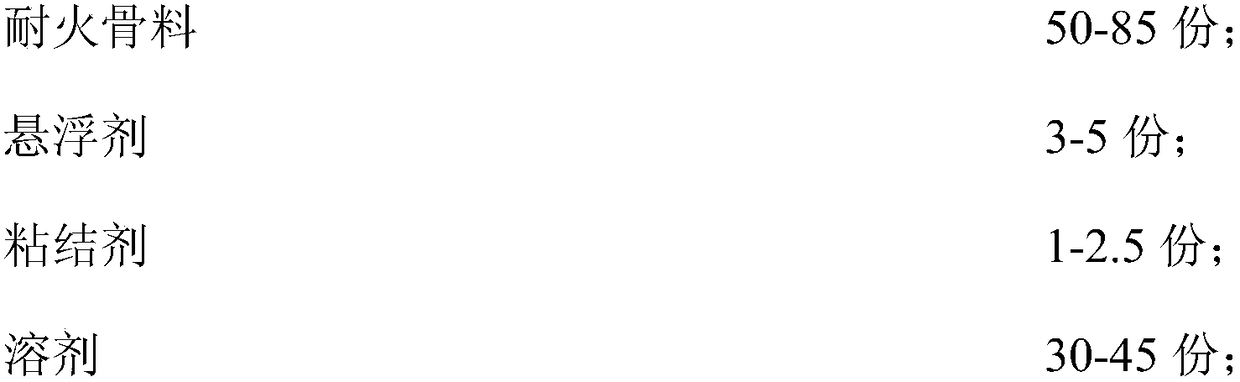

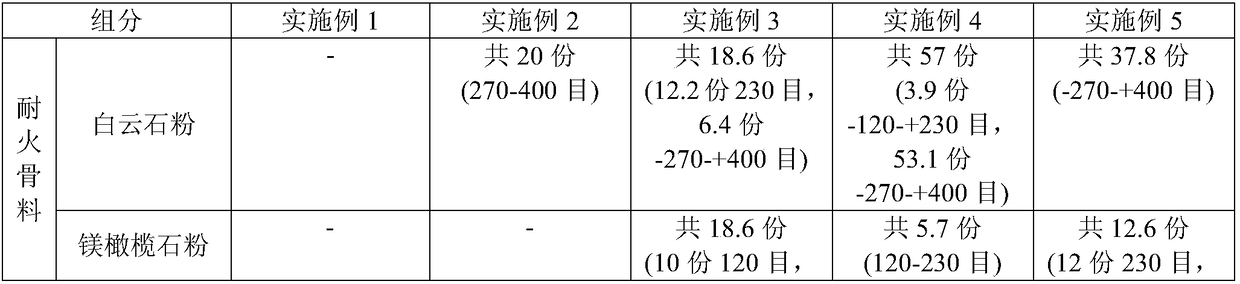

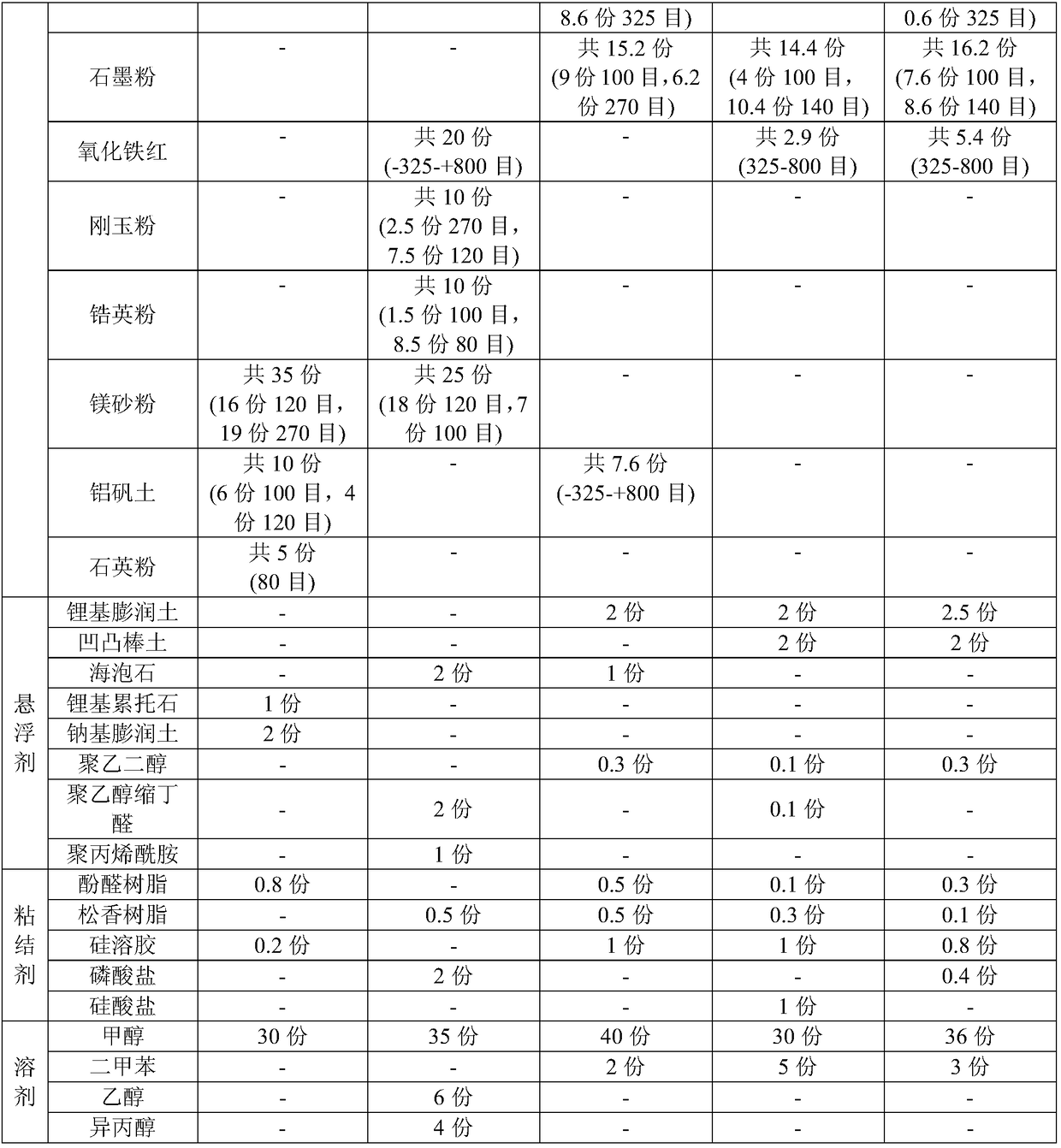

[0059] Table 1

[0060]

[0061]

[0062] In Table 1, "parts" means parts by mass, and "-" means that the content of the corresponding component is 0.

Embodiment 6

[0082] The only difference from Example 5 is that the forsterite powder is replaced by dolomite powder, and the parts by mass and particle size distribution remain unchanged.

Embodiment 7

[0084] The only difference from Example 5 is that the dolomite powder is replaced by forsterite powder, and the parts by mass and particle size distribution remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com