Coating chocolate added with beet juice powder and used for frozen drinks

A technology for frozen drinks and chocolate, applied in applications, frozen desserts, food ingredients, etc., can solve the problems of not being bright enough, not reaching the color, not satisfying consumers, etc., and achieve the effect of bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

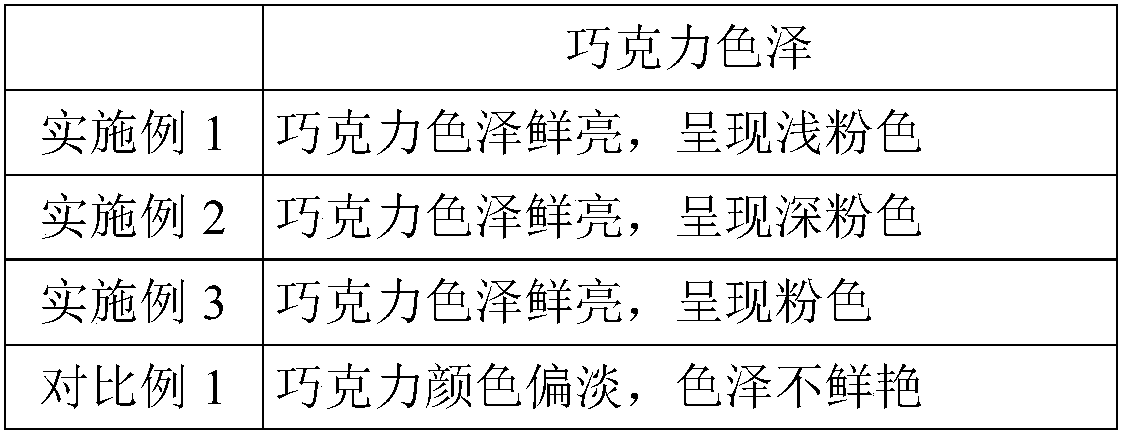

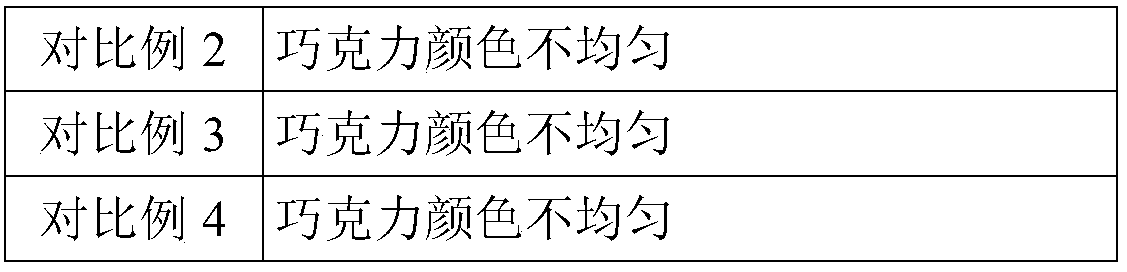

Examples

Embodiment 1

[0022] This embodiment provides a kind of coated chocolate for frozen drinks added with beet juice powder, which comprises the following raw materials in parts by weight: white granulated sugar 350kg, milk powder 150kg, cocoa liquor 140kg, natural anhydrous cream 50kg, cocoa butter 280kg, eggs Phospholipids 2kg, beet juice powder 2kg.

[0023] The chocolate is prepared by the following steps:

[0024] 1) Mix white sugar, milk powder, cocoa mass, natural anhydrous butter, cocoa butter, and lecithin to obtain a chocolate base, and heat the chocolate base to 45°C;

[0025] 2) Add 200kg of chocolate base material to the ball mill, slowly add beet juice powder (control the speed at 300g / 10min), stir fully for 10 minutes (control the stirring speed at 5000 rpm, and control the temperature at 50°C), and wait for the beet juice powder Completely disperse evenly to obtain pink chocolate mother liquor;

[0026] 3) Add the pink chocolate mother liquor to the remaining chocolate base ma...

Embodiment 2

[0028] This embodiment provides a kind of coated chocolate for frozen drinks added with beet juice powder, which comprises the following raw materials in parts by weight: white granulated sugar 330kg, milk powder 170kg, cocoa liquor 120kg, natural anhydrous cream 60kg, cocoa butter 260kg, eggs Phospholipids 1kg, beet juice powder 10kg.

[0029] The chocolate is prepared by the following steps:

[0030] 1) Mix white sugar, milk powder, cocoa mass, natural anhydrous butter, cocoa butter, and lecithin to obtain a chocolate base, and heat the chocolate base to 55°C;

[0031] 2) Take 300kg of chocolate base material and add it to the ball mill, slowly add beet juice powder (control the speed at 300g / 10min), stir fully for 15 minutes (control the stirring speed at 7000 rpm, and control the temperature at 55°C), and wait for the beet juice powder Completely disperse evenly to obtain pink chocolate mother liquor;

[0032] 3) Add the pink chocolate mother liquor to the remaining choc...

Embodiment 3

[0034] This embodiment provides a kind of coated chocolate for frozen drinks added with beet juice powder, which comprises the following raw materials in parts by weight: white granulated sugar 380kg, milk powder 130kg, cocoa liquor 160kg, natural anhydrous cream 40kg, cocoa butter 300kg, eggs Phospholipids 3kg, beet juice powder 4kg.

[0035] The chocolate is prepared by the following steps:

[0036] 1) Mix white sugar, milk powder, cocoa mass, natural anhydrous butter, cocoa butter, and lecithin to obtain a chocolate base, and heat the chocolate base to 46°C;

[0037] 2) Take 250kg of chocolate base and add it to the ball mill, slowly add beet juice powder (control the speed at 300g / 10min), stir thoroughly for 5 minutes (control the stirring speed at 6000 rpm, and control the temperature at 50°C), and wait for the beet juice powder Completely disperse evenly to obtain pink chocolate mother liquor;

[0038] 3) Add the pink chocolate mother liquor to the remaining chocolate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com