Cast-iron evaporative pattern coating and preparation method thereof

A technology of lost foam and cast iron, applied in casting molding equipment, coating, mold and other directions, can solve the problems of the decline of the grain size grade of the casting, the influence of the mechanical properties of the casting, the reduction of the gas permeability of the coating, etc. The surface is smooth and the effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Preparation of tools High-speed mixer, scale, viscosity cup

[0037] 2. Material preparation:

[0038] 320 mesh high alumina powder, perlite, sepiolite, styrene-acrylic emulsion, white latex, sodium bentonite, carboxymethyl cellulose, additives

[0039] 3. Operation method:

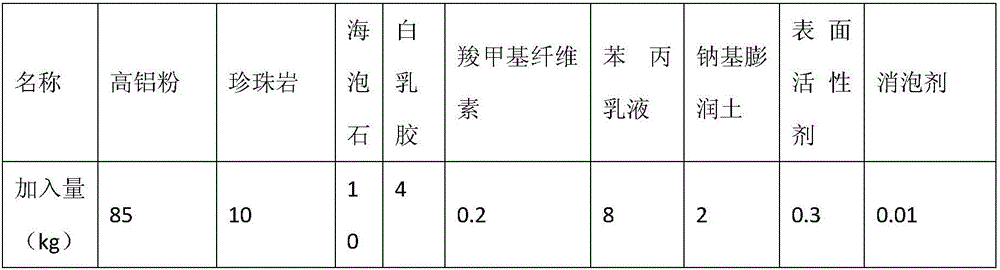

[0040] 1) The coating ratio is shown in Table 1 below:

[0041]

[0042] Table 1

[0043] Add carboxymethyl cellulose, sodium bentonite and sepiolite to water, stir at high speed for 30 minutes and soak for no less than 12 hours; then add high alumina powder, perlite, styrene-acrylic emulsion and white latex into the mixing tank, and Stir at high speed for 1-2 hours; finally add the additives and stir for 45 minutes.

[0044] Stir well and measure the viscosity (20-25 seconds) before use.

[0045] smear:

[0046] The model is dipped into the paint by rain-coating method, dip-coated three times, and dried after each dip-coating before the next dip-coating.

[0047] Allow to cool for 3-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com