Water-based paint for full mold and preparation method and using method of water-based paint

A water-based coating and lost foam technology, applied in coatings, manufacturing tools, casting and molding equipment, etc., can solve the problems of high price and high cost, and achieve the effects of low production cost, good coating and hanging performance, and high refractoriness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of lost foam water-based paint described in the embodiment of the present invention comprises a primer and a topcoat, and the primer is composed of: 10-15 parts of 200-mesh quartz powder, 10-15 parts of 270-mesh quartz powder, 1.2-1.4 parts of sodium hydroxymethyl cellulose, 1.2-1.4 parts of lithium bentonite, 0.8-1.0 parts of starch, 0.024-0.026 parts of washing powder, 0.2-0.3 parts of iron oxide, and 90-100 parts of water; The composition in parts by weight is as follows: 10-15 parts of 200-mesh quartz powder, 10-15 parts of 270-mesh quartz powder, 0.8-1.0 parts of sodium hydroxymethylcellulose, 1.1-1.3 parts of sodium bentonite, 0.8-1.0 parts of flour, washing powder 0.024-0.026 parts, 110-120 parts of water.

Embodiment 2

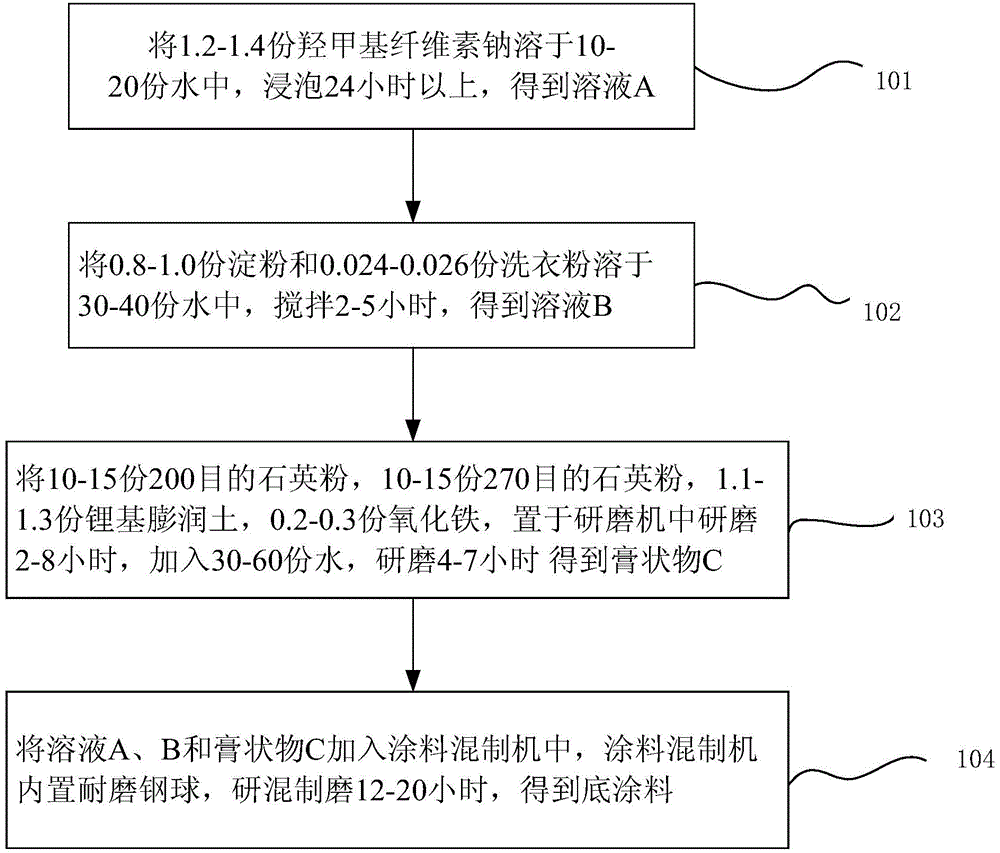

[0024] A kind of preparation method of primer as described in embodiment 1, such as figure 1 shown, including the following steps:

[0025] Step 101: Dissolving 1.2-1.4 parts of hydroxymethylcellulose sodium in 10-20 parts of water, soaking for more than 24 hours to obtain solution A;

[0026] Step 102: Dissolve 0.8-1.0 parts of starch and 0.024-0.026 parts of washing powder in 30-40 parts of water, and stir for 2-5 hours to obtain solution B;

[0027] Step 103: Put 10-15 parts of 200-mesh quartz powder, 10-15 parts of 270-mesh quartz powder, 1.1-1.3 parts of lithium-based bentonite, and 0.2-0.3 parts of iron oxide in a grinder for 2-8 hours, and add 40 -60 parts of water, grind for 4-7 hours to obtain paste C;

[0028] Step 104: Add solutions A, B and paste C into a paint mixer with built-in wear-resistant steel balls, knead and grind for 12-20 hours to obtain a primer;

Embodiment 3

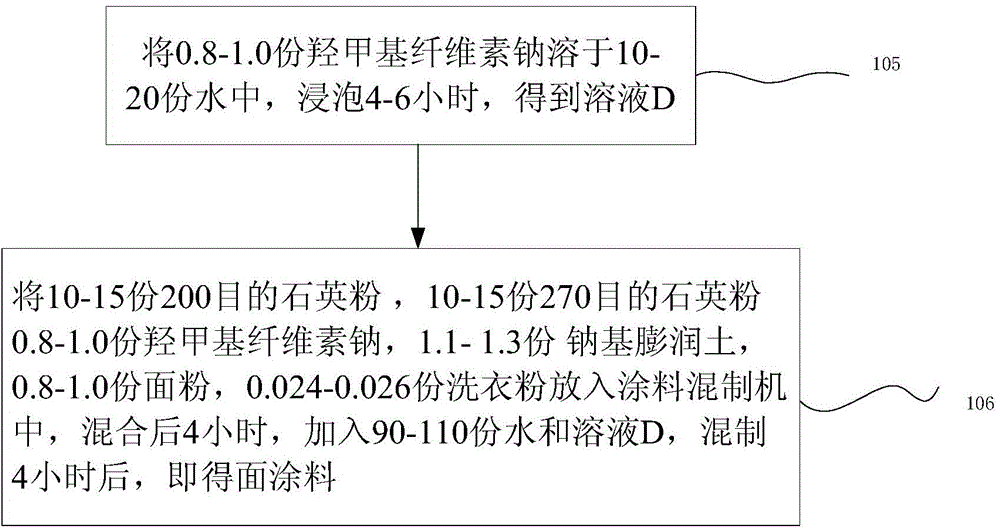

[0030] A kind of preparation method of top coating as described in embodiment 1, such as figure 2 shown, including the following steps:

[0031] Step 105: Dissolving 0.8-1.0 parts of hydroxymethylcellulose sodium in 10-20 parts of water, soaking for 4-6 hours to obtain solution D;

[0032] Step 106: Mix 10-15 parts of 200-mesh quartz powder, 10-15 parts of 270-mesh quartz powder, 0.8-1.0 parts of sodium hydroxymethylcellulose, 1.1-1.3 parts of sodium bentonite, 0.8-1.0 parts of flour, 0.024-0.026 Put one part of washing powder into the paint mixer, and after 4 hours of mixing, add 90-110 parts of water and solution D, and mix for 4 hours to get the top coat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com