Production method of environment-friendly dual-purpose coating suspending agent

A production method and technology of suspending agent, applied in the direction of coating, casting mold, core, etc., can solve the problems of high cost, unsatisfactory performance, limited application scope, etc., and achieve the effect of simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

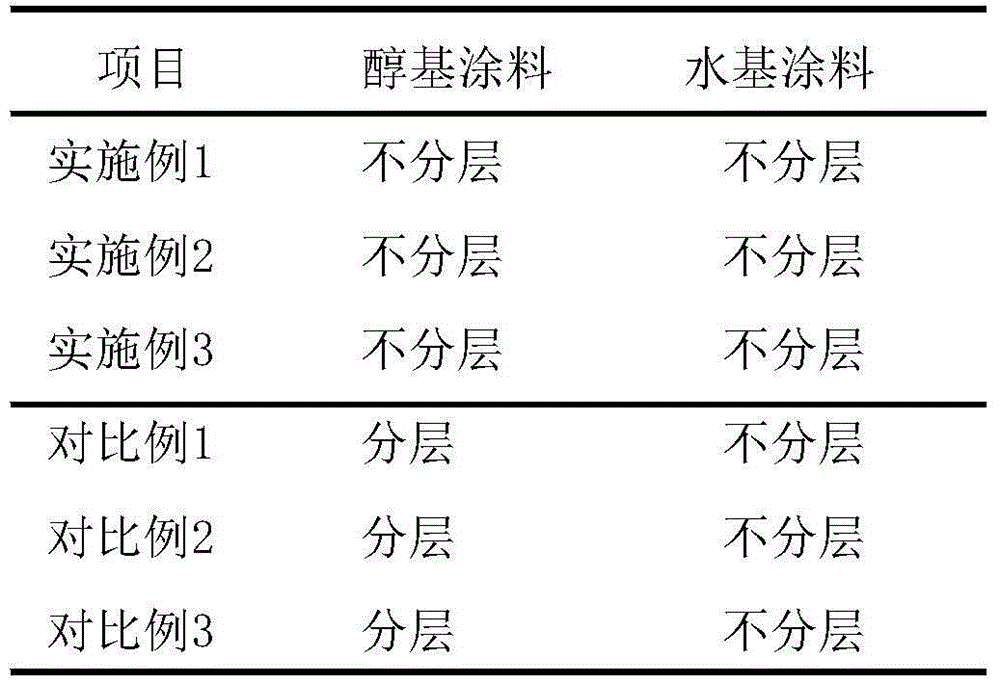

Examples

Embodiment 1

[0033] The present embodiment relates to a kind of production method of environmental protection dual-purpose type paint suspending agent, is made up of following steps:

[0034] Step 1, stir 20kg bentonite, 1kg sodium carbonate and 6kg water evenly, then crush the pair of rolls twice, stack them for 17 hours, control the weight percentage water content of the pair of roll sheets to be 33%, and obtain modified bentonite;

[0035] Step 2, mixing the modified bentonite with 75kg attapulgite clay, 4kg lithium carbonate and 15kg water, crushing the pair of rolls twice, stacking for 36 hours, controlling the weight percentage water content of the pair of roll sheets to be 45%;

[0036] Step 3: Air-dry or dry the product obtained in Step 2 naturally, crush it, and grind it to a solid powder of 150 meshes.

Embodiment 2

[0038] The present embodiment relates to a kind of production method of environmental protection dual-purpose type paint suspending agent, is made up of following steps:

[0039]Step 1: Stir 10kg of bentonite, 1.5kg of sodium carbonate and 5kg of water evenly, then crush the pair of rolls twice, stack them for 24 hours, control the weight percentage water content of the pair of roll sheets to be 30%, and obtain modified bentonite;

[0040] Step 2, mixing the modified bentonite with 65kg attapulgite clay, 5kg lithium carbonate and 10kg water, crushing the pair of rolls twice, stacking them for 24 hours, controlling the weight percentage water content of the pair of roll sheets to be 50%;

[0041] Step 3, the product obtained in step 2 is air-dried or dried naturally, crushed, and ground to 200-mesh solid powder.

Embodiment 3

[0043] The present embodiment relates to a kind of production method of environmental protection dual-purpose type paint suspending agent, is made up of following steps:

[0044] Step 1: Stir 30kg of bentonite, 0.5kg of sodium carbonate and 4kg of water evenly, then crush the pair of rolls twice, stack them for 10 hours, control the weight percentage water content of the pair of roll sheets to be 35%, and obtain modified bentonite;

[0045] Step 2, mixing the modified bentonite with 85kg attapulgite clay, 3kg lithium carbonate and 13kg water, crushing the pair of rolls twice, stacking for 48 hours, and controlling the weight percentage water content of the pair of roll sheets to be 40%;

[0046] Step 3, the product obtained in step 2 is air-dried or dried naturally, crushed, and ground to 300-mesh solid powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com