Flock breeding individual sorting system

A sorting system and individual technology, applied in the field of livestock breeding group sorting, can solve the problems of difficult sorting, high degree of manual participation, and low sorting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

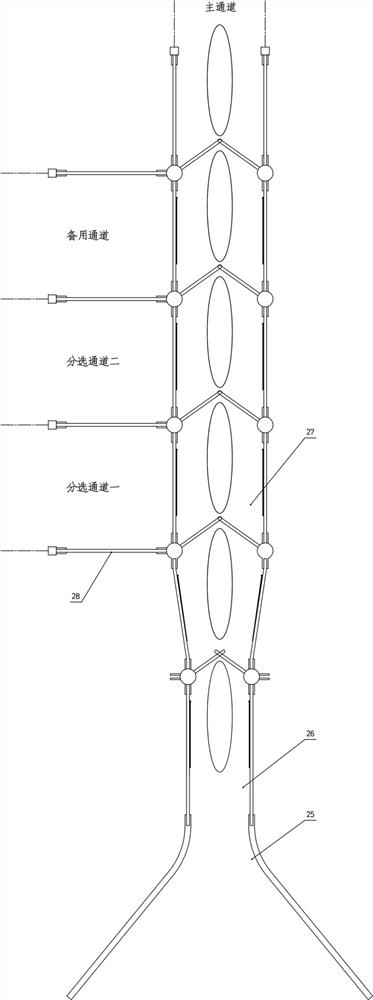

[0028] Example 1: A flock breeding individual sorting system adopts such as figure 1 shown in the form of structure, from figure 1 It can be seen that the system consists of a main channel and multiple sorting channels. The inlet end of the main channel 27 is provided with a conical inlet 25, which is further connected with a restricting channel 26, which is used to compress the two side walls to ensure that only one sheep passes through. And then connect the main part of the main channel. Usually, the main channel is used as the output channel of the main population (normal population), and the sorting channel is used as the sorting channel for a small number of different populations.

[0029] There are multiple detection areas in the main part of the main channel, figure 1 Take three detection zones as an example. Each detection area includes two side walls, and each detection area has a pair of revolving door systems in front of it, and the adjacent detection areas are ...

Embodiment 2

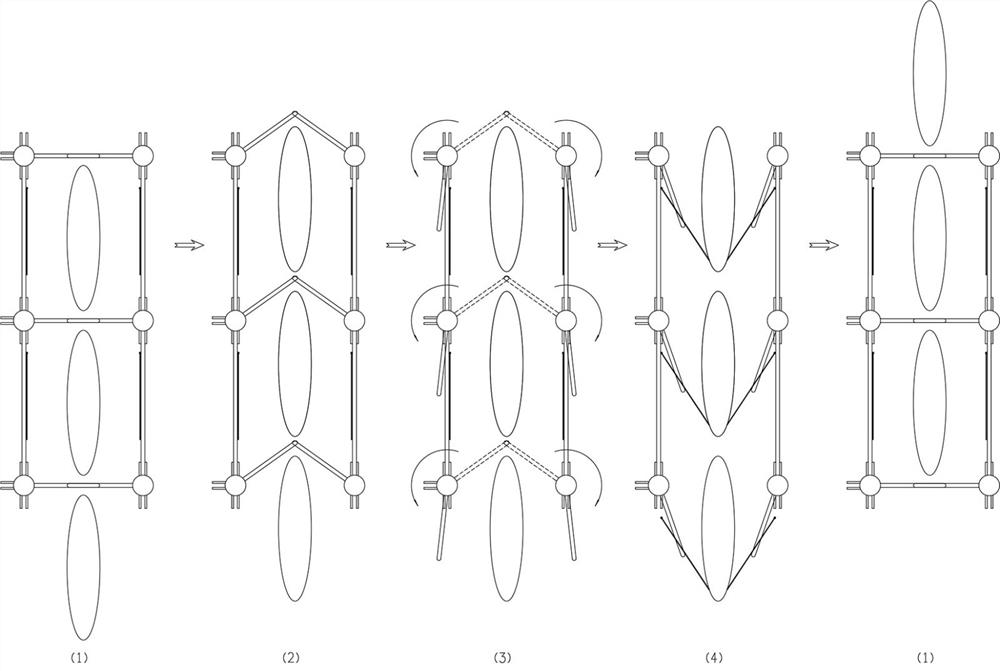

[0037] Example 2: On the basis of Example 1, for the motion state of each revolving door system in one rotation cycle, such as figure 2 In step (4), the auxiliary push component is set to automatically drive the individual sheep forward. The side wall is provided with an auxiliary push assembly such as Figure 4 As shown, it includes components such as auxiliary push plate 17 and U-shaped link telescopic mechanism.

[0038] Specifically, a fixed seat 16 is installed on the inner side rail of the side wall, and the auxiliary push plate 17 is hinged on the fixed seat 16. In this embodiment, a plurality of horizontally parallel auxiliary push plates 17 pass through the vertical connecting plate in the middle 19 are fastened together to form a composite push plate. The U-shaped connecting rod telescopic mechanism is that two pairs of guide sleeves 20 and two U-shaped connecting rods 21 are fixed on the inner side crossbar of the side wall. The two wing rods of each U-shaped li...

Embodiment 3

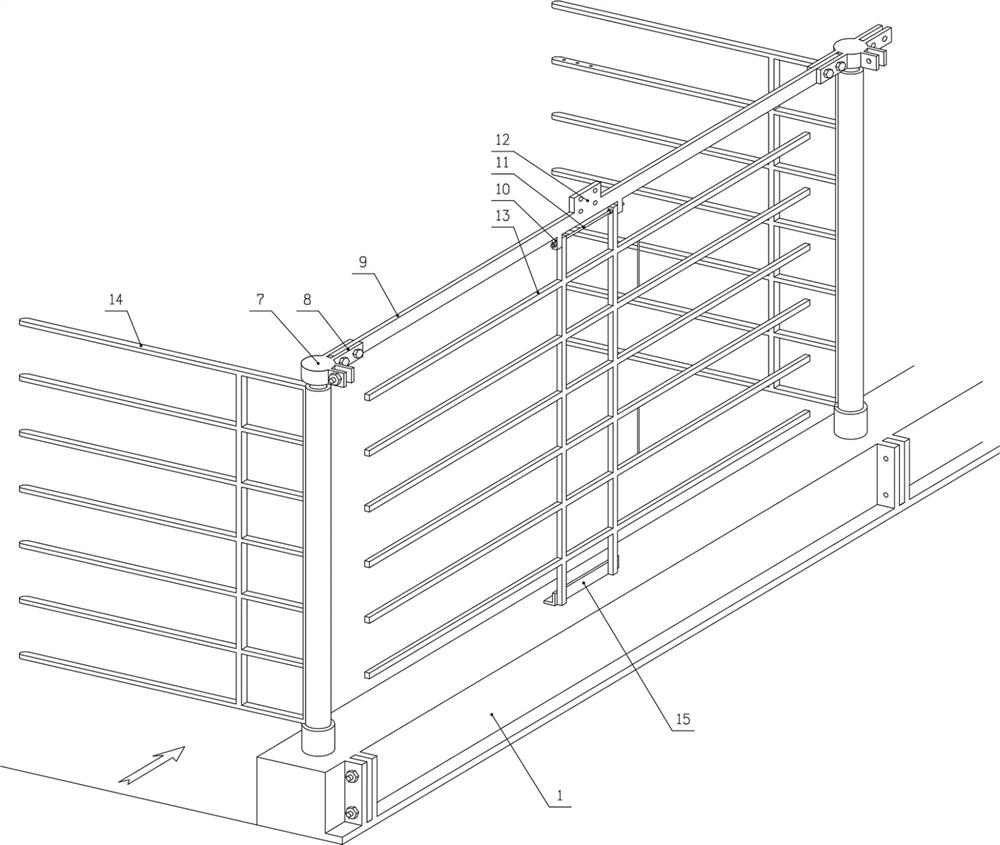

[0041] Embodiment 3: On the basis of Embodiment 1, the rotating column assembly in this embodiment is a cylindrical fixed column that can rotate the rotating drum 6 and cannot be rotated, and a cylindrical fixed column is sleeved inside the rotating drum 6 . The lower end of the cylindrical fixed column is fixed in the corresponding lower sleeve in the base, and the upper end of the cylindrical fixed column is fixed with the upper sleeve. Both ends of the connecting rod 9 are respectively connected to the upper sleeves on the upper parts of the front and rear adjacent rotating column assemblies.

[0042] A drum seat 29 is provided on the base 1 for installing the drum 6 , and a composite pulley is installed on the inner part of the drum 6 extending into the base 1 . The transmission mechanism provided in the base 1 drives the rotating drum to rotate. Specifically, a composite pulley 4 is installed under each rotating drum 6, and the adjacent composite pulleys are connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com