Magnesium alloy furnace material fluxless remelting refining method and device

A magnesium alloy and flux-free technology is applied to the field of a flux-free remelting refining method for magnesium alloy charge and its device, which can solve problems such as clogging of a filter device and achieve the effect of improving refining efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

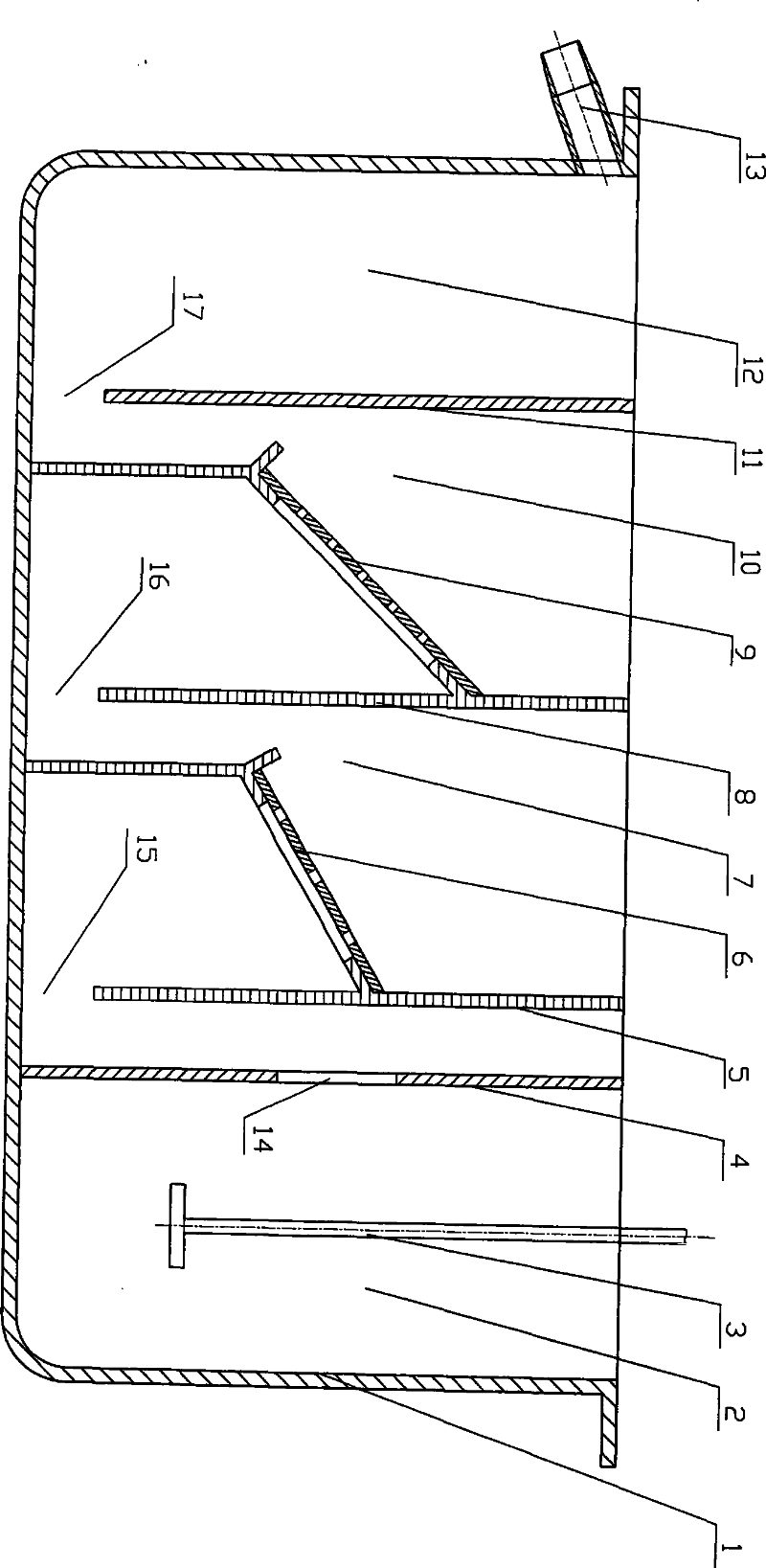

Image

Examples

Embodiment 1

[0034] Put the preheated and dried die-casting AD91 magnesium alloy scrap into a crucible with a temperature of 680-800°C to melt, seal the crucible and use CO 2 and SF 6 Mixed gas protection, after the melting is complete, use mechanical stirring and blowing gas to refine the magnesium melt for 10 minutes, and the flow rate of argon gas is controlled at 0.15m 3 / h, the gas purity is 99.9%, the distance from the stirring head for stirring and refining to the bottom of the crucible is about 400mm, then stop stirring and blowing for refining, continue to feed the material to the forward processing chamber, stop the feeding, wait for the melting to complete, stir and blow Refining for 10 minutes, this cycle is carried out; there are 2 filter chambers in the crucible, each filter chamber is equipped with a first-level filter mechanism, the apertures are 3mm and 1.5mm, and the corresponding filter orifice is clamped with the direction of the melt flowing into the filter orifice. T...

Embodiment 2

[0036] Put the preheated and dried AM50 magnesium alloy waste into the refining device of Example 1, and its corresponding technical parameters are: use mechanical stirring and refining, the distance from the stirring head for stirring and refining to the bottom of the crucible is about 100 mm, and the stirring and refining time is about 100 mm. 30min, the melt was left in the pouring chamber for 80min and then came out of the furnace for continuous pouring, and its technical parameters were the same as in Example 1. The analysis result of the sample shows that the tensile strength of the sample reaches above 191MPa, and the elongation reaches 8.5%, reaching the standard of new magnesium alloy material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com