High voltage splitflow type fuse

A fuse, shunt technology, applied in the field of high-voltage line protection devices, can solve the problems of power failure maintenance, economic losses, etc., to achieve the effect of blocking economic losses and the continuous smooth flow of the power grid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

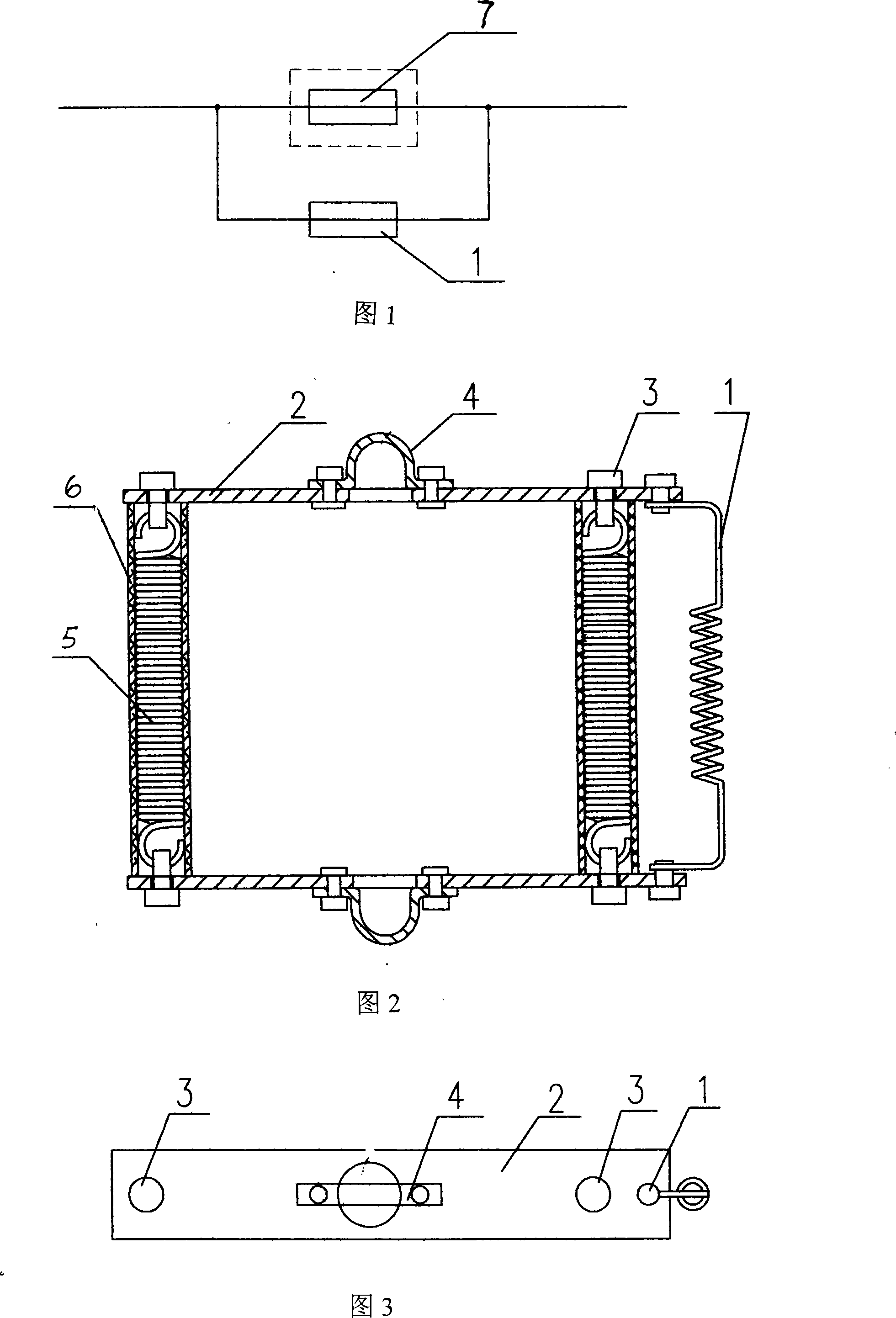

[0012] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0013] A high-voltage shunt fuse, comprising a shunt rubber fuse 1, upper and lower copper conductive contact plates 2, upper and lower insulating columns 3, upper and lower hanging rings 4, left and right tension springs 5, and insulating sleeves 6.

[0014] A total of four insulating columns 3 are arranged on the two ends of the upper and lower copper conductive contact plates 2, and the upper and lower corresponding insulating columns 3 are hooked with the tension spring 5, and an insulating sleeve 6 is arranged outside the tension spring 5. The shunt rubber sleeve fuse 1 is connected to both ends of the upper and lower copper conductive contact plates 2, the rated current of the shunt rubber sleeve fuse 1 is the same as the rated current of the high voltage drop fuse 7, and the middle of the upper and lower copper conductive contact plates 2 The posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com