Lens continuous pouring system and process thereof

A pouring system and lens technology, which is applied to other household appliances, household appliances, optical components, etc., can solve the problems of troublesome switching between molds and molds, affecting production efficiency and product quality, and achieve efficiency improvement, production efficiency, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

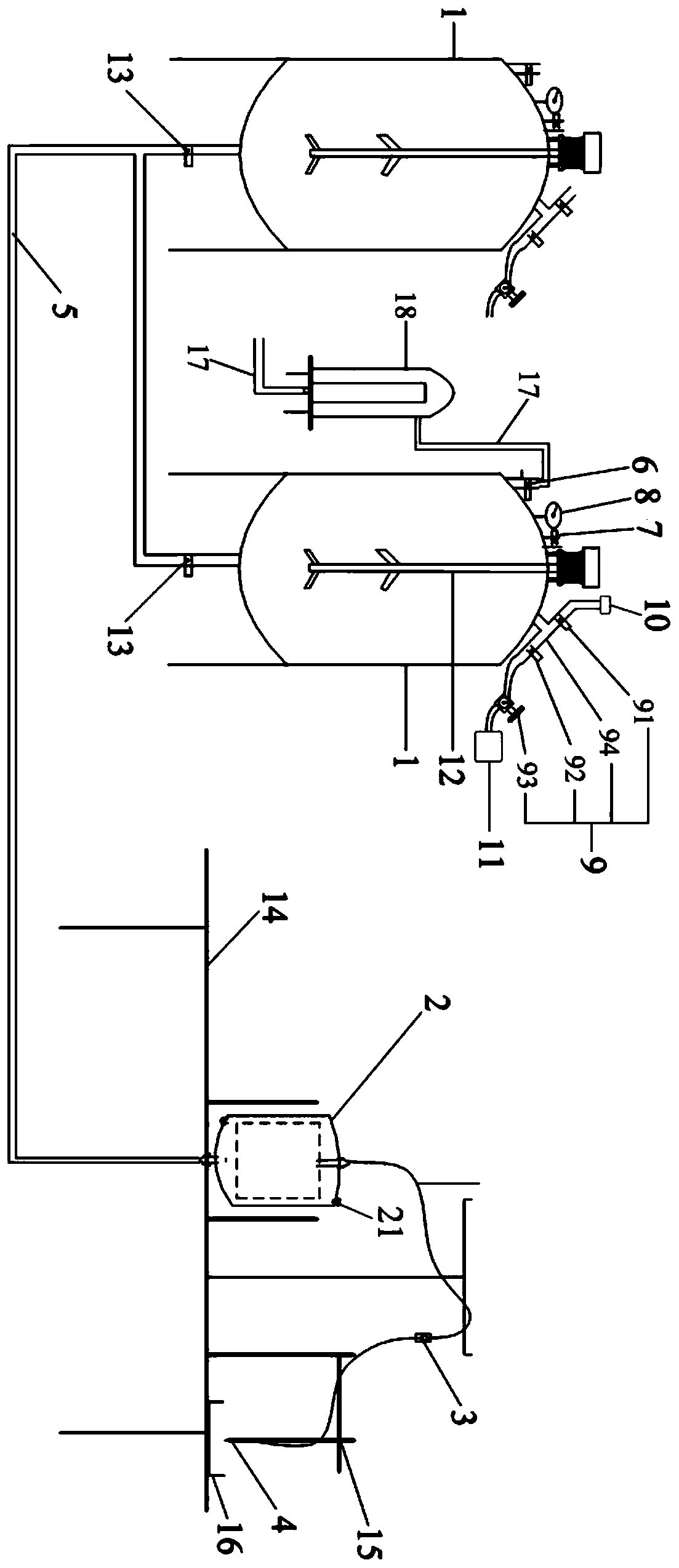

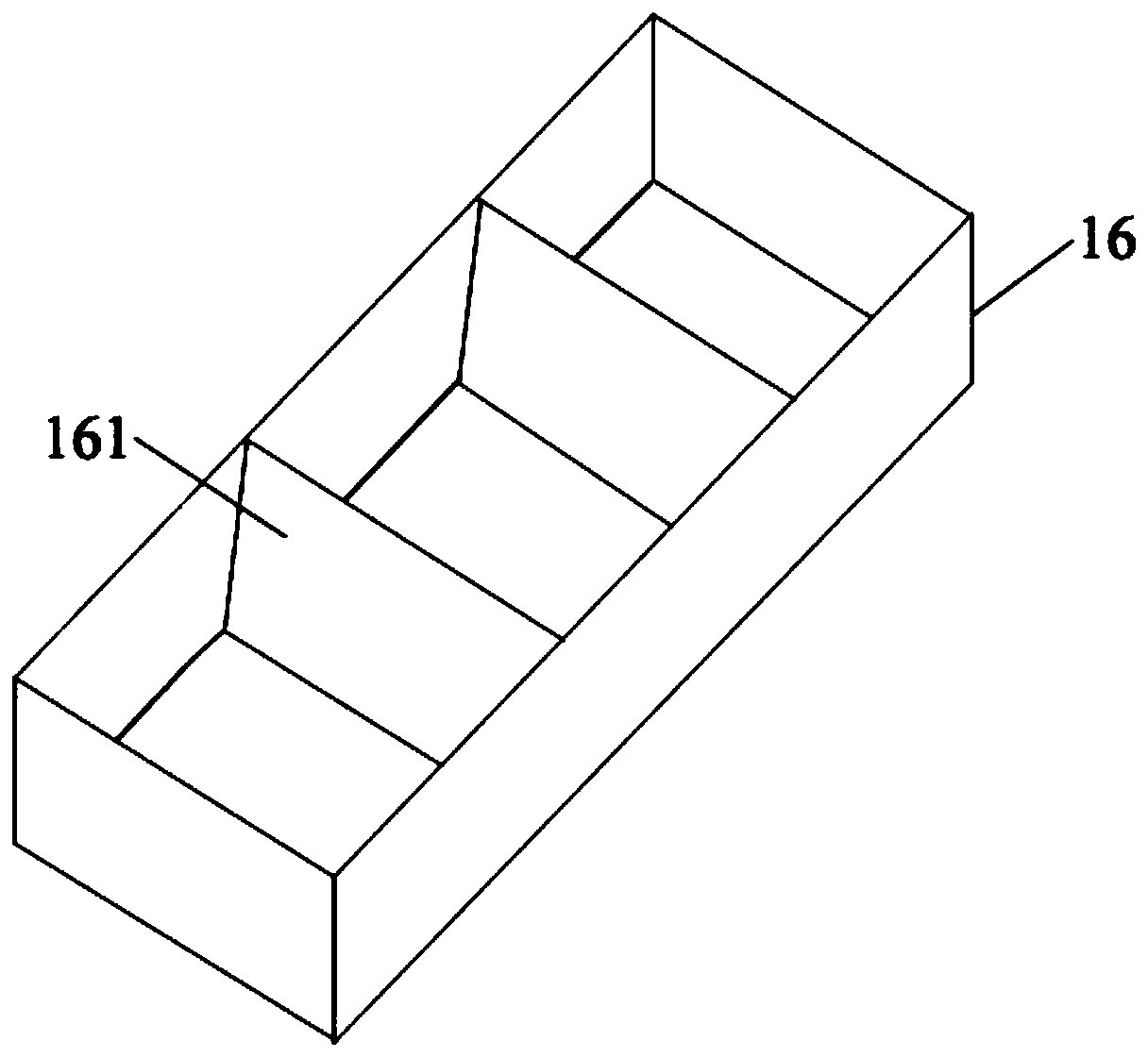

[0041] according to figure 1 and figure 2 A continuous pouring system for lenses is shown, which includes a material tank 1 sequentially connected through a pouring pipeline 5, a filter device 2 that is easy to remove air bubbles, a pouring valve 3 and a pouring needle 4, and the pouring needle 4 is fixed on the On the pouring rack 15 on the pouring table 14, on the pouring table 14 at the lower end of the pouring needle 4, a mold push plate 16 containing multiple spaces is placed, and the top of the material tank 1 is provided with a feed inlet 6 and an exhaust valve. 7 and a pressure control assembly 9, the bottom of which is provided with a discharge valve 13, one end of the pressure control assembly 9 is connected to a vacuum generating device 10, and the other end is connected to a compressed air device 11; an agitator 12 is installed inside the material tank 1.

[0042] The pressure control assembly 9 in this embodiment includes a pressure pipeline 94, on which a vacuu...

Embodiment 2

[0049] A continuous casting process for old light lenses based on the continuous casting system for lenses of the present invention, comprising the following steps:

[0050] 1) Open the vacuum valve 91 and vacuumize the material tank 1 to 0.04-0.09MP;

[0051] 2) Open the feed inlet 6, and pump the lens feed liquid into the feed tank 1 through the feed pipe 17;

[0052] 3) Keep the vacuum, turn on the agitator 12, until the lens feed liquid in the material tank 1 is uniform;

[0053] 4) Stop stirring, keep the vacuum at 0.09-0.11MP, and vacuum defoam the lens material in material tank 1;

[0054] 5) Close the vacuum valve 91, open the pressure regulating valve 92, adjust the pressure reducing valve 93, and control the pouring pressure to 0.05MP;

[0055] 6) Open the discharge valve 13 and the pouring valve 3 of a material tank to allow the lens material liquid to flow out. When the lens material liquid passes through the filter device 2 that is easy to remove air bubbles, op...

Embodiment 3

[0061] A continuous casting process for myopia lenses based on the continuous casting system for lenses of the present invention, comprising the following steps:

[0062] 1) Open the vacuum valve 91 and vacuumize the material tank 1 to 0.04-0.09MP;

[0063] 2) Open the feed inlet 6, and pump the lens feed liquid into the feed tank 1 through the feed pipe 17;

[0064] 3) Keep the vacuum, turn on the agitator 12, until the lens feed liquid in the material tank 1 is uniform;

[0065] 4) Stop stirring, keep the vacuum at 0.09-0.11MP, and vacuum defoam the lens material in material tank 1;

[0066] 5) Close the vacuum valve 91, open the pressure regulating valve 92, adjust the pressure reducing valve 93, and control the pouring pressure to 0.08MP;

[0067] 6) Open the discharge valve 13 and the pouring valve 3 of a material tank to allow the lens material liquid to flow out. When the lens material liquid passes through the filter device 2 that is easy to remove air bubbles, open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com