Pasting process of polyimide film on the surface of honeycomb structure board

A technology of polyimide film and honeycomb structure, applied in lamination auxiliary operations, chemical instruments and methods, lamination, etc., can solve problems such as poor bonding performance, failure of commercial satellites, insufficient bonding strength, etc., and achieve reduction The effect of production cost, improvement of curing efficiency, and good paste quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

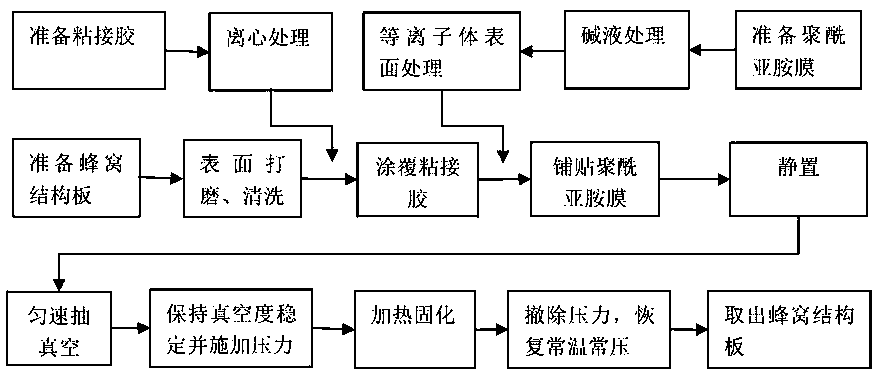

[0036] A kind of pasting process of polyimide film on the surface of honeycomb structure board, its pasting process is as follows figure 1 shown, including the following steps:

[0037] (1) Pretreatment of polyimide membrane:

[0038] (1.1) Alkali treatment: put the polyimide film with a thickness of 50 microns in pure water for 15 minutes, and then soak it in a sodium hydroxide solution with a concentration of 2mol / L at 40°C. Lye treatment was carried out for 20 minutes.

[0039] (1.2) Cleaning: Wash the polyimide membrane obtained after the lye treatment in step (1.1) with pure water until the pH value of the washing solution is neutral, then clean it with tetrahydrofuran, acetone, and alcohol in sequence, and let it dry in the air. Dry. According to the observation of microscopic morphology, the surface corrosion depth of the polyimide film was about 500 nanometers after the alkali treatment, and a nano-velvet surface was formed on the surface, showing a nano-velvet stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com