A New Chromatographic Column with Exhaust

A chromatographic column and exhaust pipe technology, applied in the field of preparative chromatography, can solve the problems of difficult operation, increase production cost, and reduce the effective height of the column, and achieve the effects of convenient processing, lower overall height, and lower height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

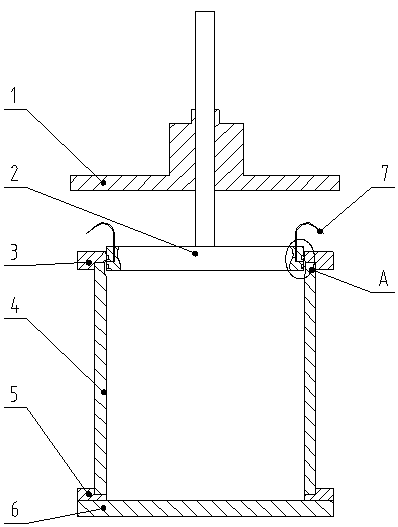

[0015] The present invention will be further described in detail with reference to Fig. 3 to Fig. 8 .

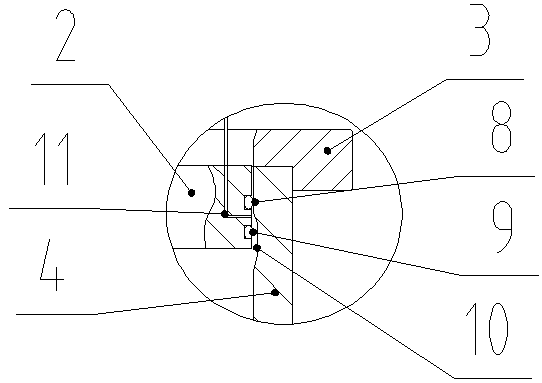

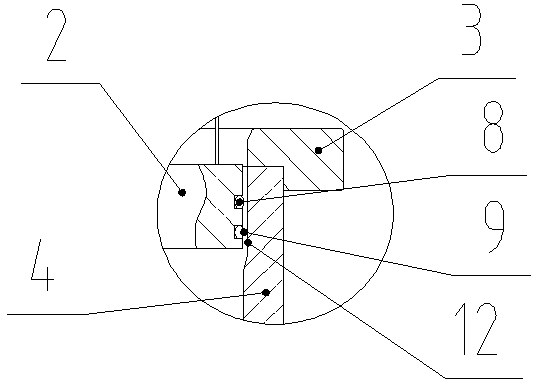

[0016] The first embodiment of the present invention is shown in Figures 3 to 5, consisting of a piston support assembly 1, a piston 2, a column upper flange 3, a column 4, a column lower flange 5, an end cover assembly 6, and an exhaust pipe 7. Seal ring A 8, seal ring B 9 and exhaust groove 10 are formed. Piston 2 is provided with two exhaust holes 11, and exhaust hole 11 is connected with exhaust pipe 7.

[0017] When the chromatographic column is exhausted, move the piston 2 to the exhaust position (as shown in Figure 3), the sealing ring A 8 is fitted and sealed with the upper flange 3 of the column cylinder, and the sealing ring B 9 is in the position of the exhaust groove (10). An unsealed state is formed, and the exhaust hole 11 on the piston 2 and the exhaust pipe 7 communicate with the outside world. The granular medium is pumped into the cylinder 4 from the end c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com