Improved internal combustion engine burner

A combustion device and internal combustion engine technology, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of low combustion efficiency and unclean exhaust gas discharge, and achieve sufficient and good combustion, smooth gas exchange, and variable compression ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

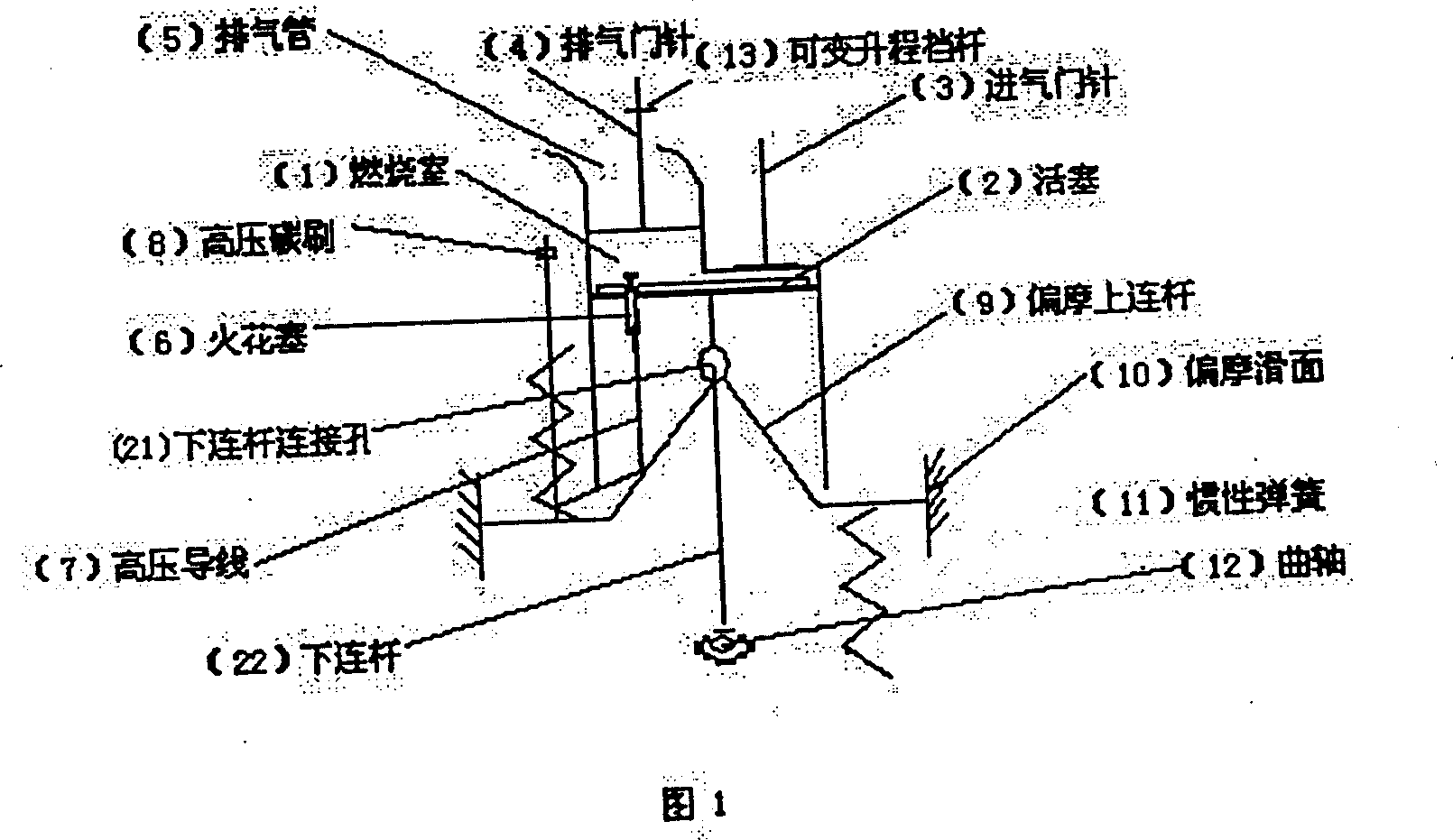

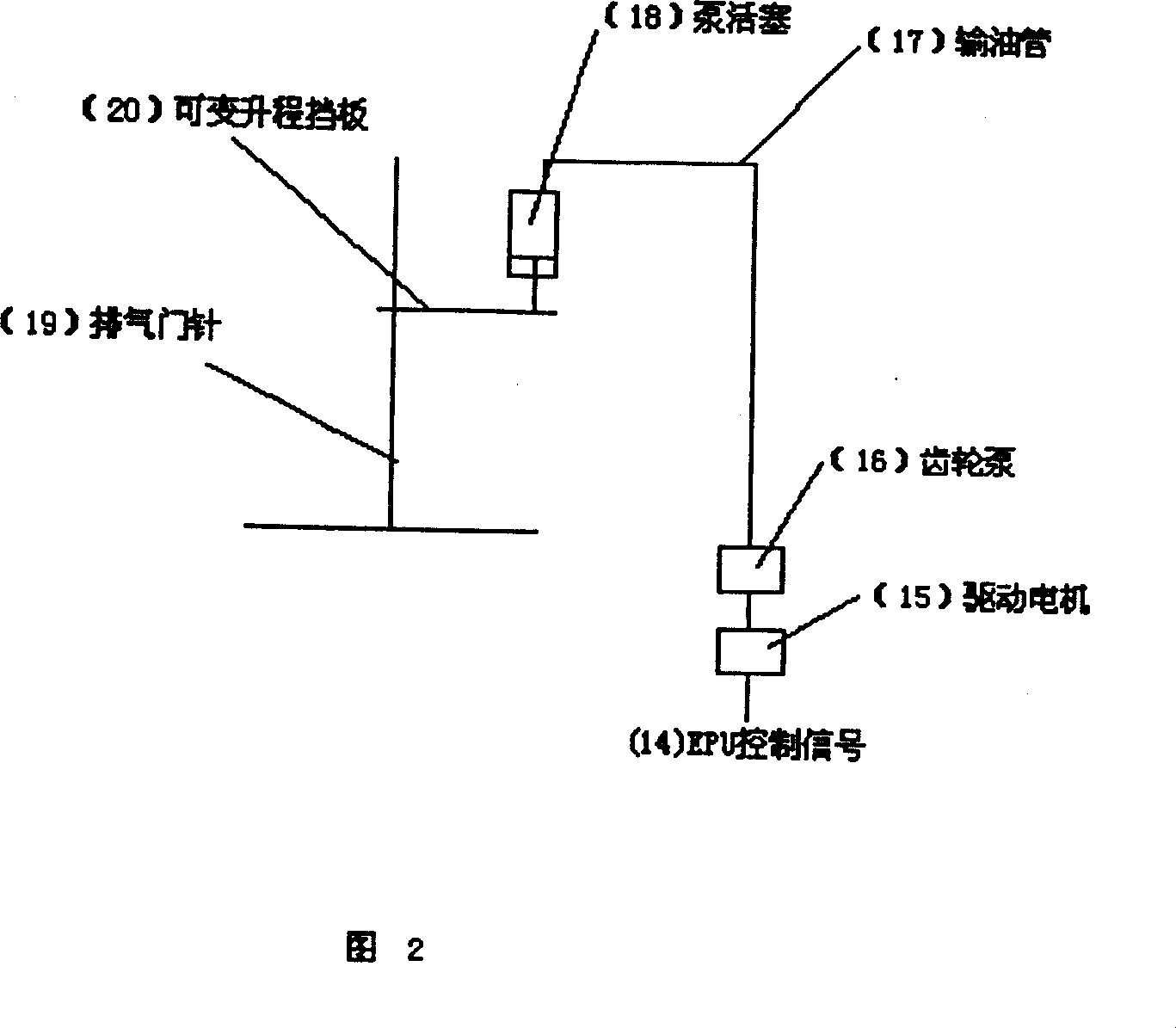

[0006] (4) The exhaust valve needle is used as the only top of the (1) combustion chamber and (5) the exhaust pipe part is completely sealed to form the combustion chamber. When the piston (2) is compressed, (4) the exhaust valve needle moves upward to a certain position, its upper limit is determined by (10) pump piston, (13) variable lift and stop lever and (14) EPU signal. At this time, the combustion chamber is only composed of (5) exhaust pipe and (4) exhaust valve needle In that section (combustion chamber size, extensibility, and lower edge can be customized according to needs), during the exhaust stroke, the valve mechanism makes the exhaust valve fully open when the piston is at the bottom dead center according to the movement process of the piston. (4) The exhaust valve needle uses the negative pressure generated by the spring to take the exhaust gas out of the combustion chamber, and at the same time absorbs fresh air. The inertial spring flips back and forth for ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com