A kind of production method of artificial stone

A production method and artificial stone technology, which can be used in manufacturing tools, supply devices, ceramic molding machines, etc., can solve problems such as poor product quality, and achieve the effects of reduced equipment costs, high product compactness, and high product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

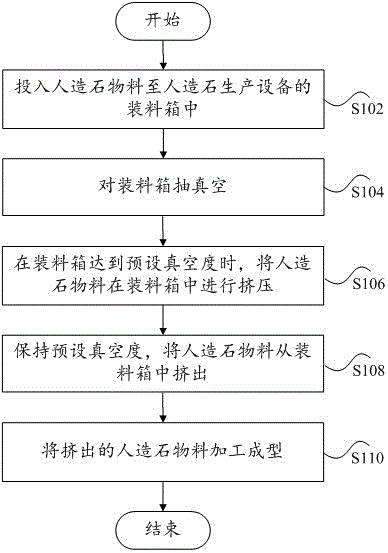

[0020] figure 1 It is a flow chart of the artificial stone production method according to the first embodiment of the present invention, as figure 1 As shown, the method includes the following steps S102 to S110.

[0021] Step S102: Putting artificial stone materials into the charging box of the artificial stone production equipment.

[0022] Step S104: Vacuum the charging box, for example, a pipeline connected to a vacuum device is provided on the box body or the sealing cover of the charging box, and the charging box is vacuumed through the vacuum device and the pipeline.

[0023] Step S106: When the charging box reaches the preset vacuum degree, squeeze the artificial st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com